Polyamine inhibitor for drilling fluids and method for preparing polyamine inhibitor

A polyamine inhibitor and drilling fluid technology, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problem of not being able to well inhibit the hydration expansion of mud shale and that the treatment agent cannot reach the storage area. problems such as layer protection and environmental protection, to achieve the effects of wellbore cleaning, guaranteed performance, and high-temperature rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

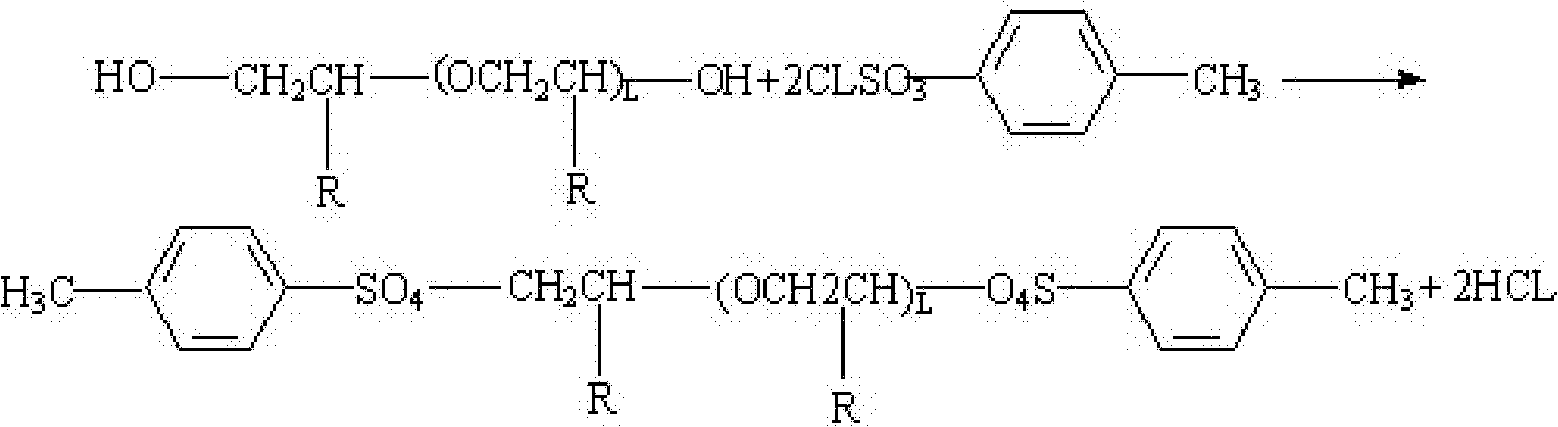

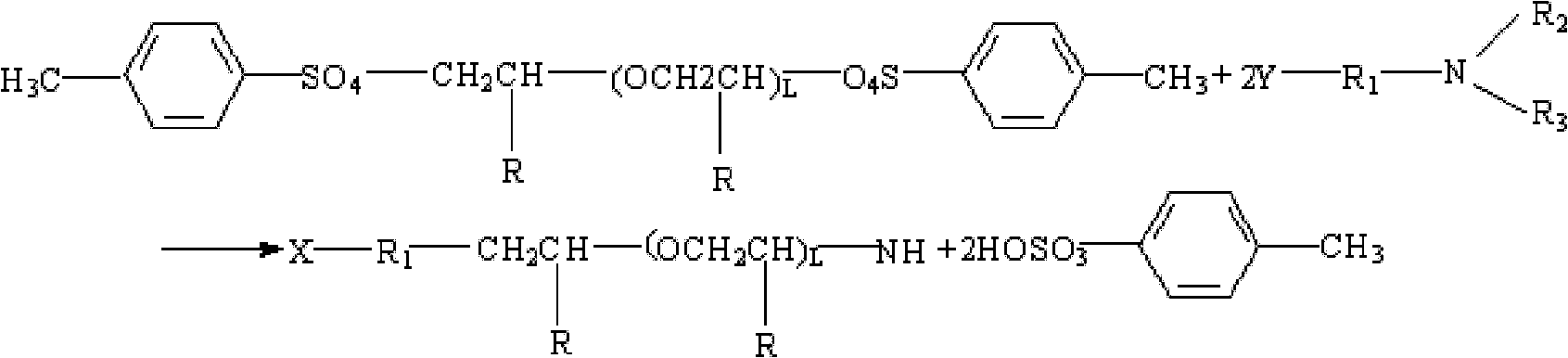

Method used

Image

Examples

Embodiment 1

[0024] Take 60g of hydroxyl-terminated polybutadiene (molecular weight: 2000), 58g of p-toluenesulfonyl chloride, and 69.2g of pyridine into a three-necked flask, maintain the temperature at about 20°C, and stir to dissolve. The reaction time was 13 hours. After the reaction is completed, filter to obtain a light yellow liquid, which is dissolved in water. After static phase separation, the lower layer liquid is removed, and the water is distilled off under reduced pressure to obtain the terminal sulfoester compound. Take another three-neck flask (with a stirring reflux device), add 32.5g of m-phenylenediamine, 90ml of precipitant toluene, heat up to 85°C, start to reflux, add the above esterification solution dropwise, react for 2 hours, cool and filter to obtain Pale yellow liquid, the solvent and m-phenylenediamine are distilled off under reduced pressure to obtain the polyamine inhibitor.

[0025] The total reaction yield is 92.6%, and the viscosity is 10.2mPa.S.

Embodiment 2

[0027] Take 40g of hydroxyl-terminated polybutadiene (molecular weight: 1000), 100g of methanesulfonyl chloride, and 120g of sodium carbonate into a three-necked flask, maintain the temperature at about 10°C, and stir to dissolve. The reaction time was 11 hours. After the reaction is completed, filter, dissolve the filtrate in water, and after static phase separation, take the liquid in the lower layer, and distill under reduced pressure to remove the water to obtain the terminal sulfoester compound. Take another three-neck flask (with a stirring reflux device), add 90.2g of polypropylene glycol diamine, 150ml of precipitant DMF, heat up to 90°C, start to reflux, add the above esterification solution dropwise, react for 3 hours, cool and filter to obtain a shallow Yellow liquid, distilled off under reduced pressure to remove the solvent and polypropylene glycol diamine to obtain the polyamine inhibitor.

[0028] The total reaction yield is 94.3%, and the viscosity is 7.8mPa.S...

Embodiment 3

[0030] Take 20g of hydroxyl-terminated polybutadiene (molecular weight: 400), 190g of toluenesulfonyl chloride, and 92g of triethylamine into a three-necked flask, maintain the temperature at about 15°C, and stir to dissolve. The reaction time was 8 hours. After the reaction is completed, filter, dissolve the filtrate in water, and after static phase separation, take the liquid in the lower layer, and distill under reduced pressure to remove the water to obtain the terminal sulfoester compound. Take another three-neck flask (with a stirring reflux device), add 56.2 g of butylamine, 200 ml of cyclohexane as a precipitating agent, raise the temperature to 120 ° C, start to reflux, add the above esterification solution dropwise, react for 2 hours, cool and filter to obtain Pale yellow liquid, distilled off under reduced pressure to remove the solvent and butylamine to obtain the polyamine inhibitor.

[0031] The total reaction yield is 96.7%, and the viscosity is 6.4mPa.S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com