A kind of preparation method of anti-high temperature binary copolymerization low molecular weight polyamine inhibitor for water-based drilling fluid

A polyamine inhibitor, water-based drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as poor temperature resistance and stability, achieve good inhibition performance, and improve wellbore stability. Effect

Active Publication Date: 2022-06-03

DAQING PETROLEUM ADMINISTRATION +1

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

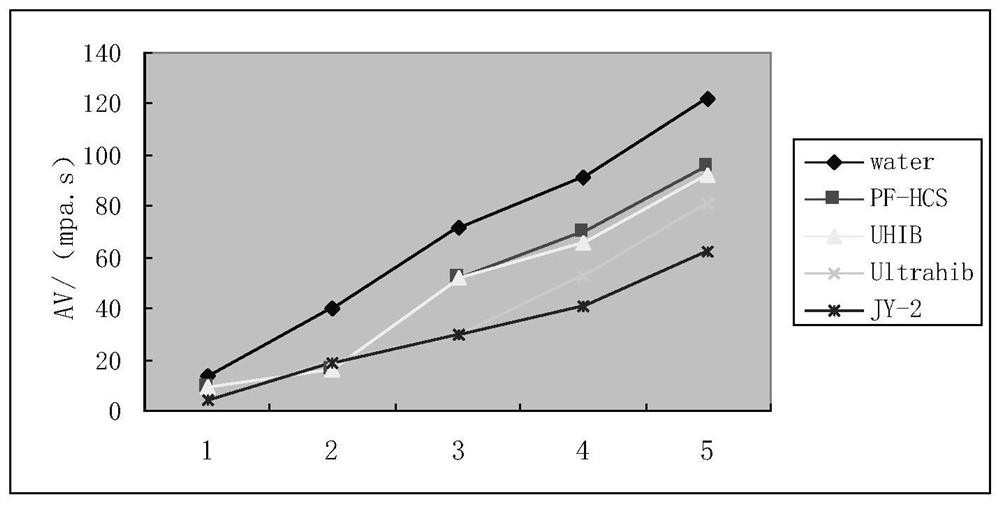

[0005] The present invention aims to overcome the problems of poor temperature resistance and poor stability of existing inhibitors in the background technology, and provides a method for preparing a high-temperature resistant binary copolymerized low-molecular-weight polyamine inhibitor for water-based drilling fluids. The water-based drilling fluid The anti-high temperature binary copolymerization low molecular weight polyamine inhibitor for liquid has stronger temperature resistance and stability, which can improve the inhibitory effect of water-based drilling fluid on shale formations, improve the stability of the well wall, reduce downhole complexity, and promote water-based drilling. Advances in base drilling fluid technology and smooth oil and gas exploration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

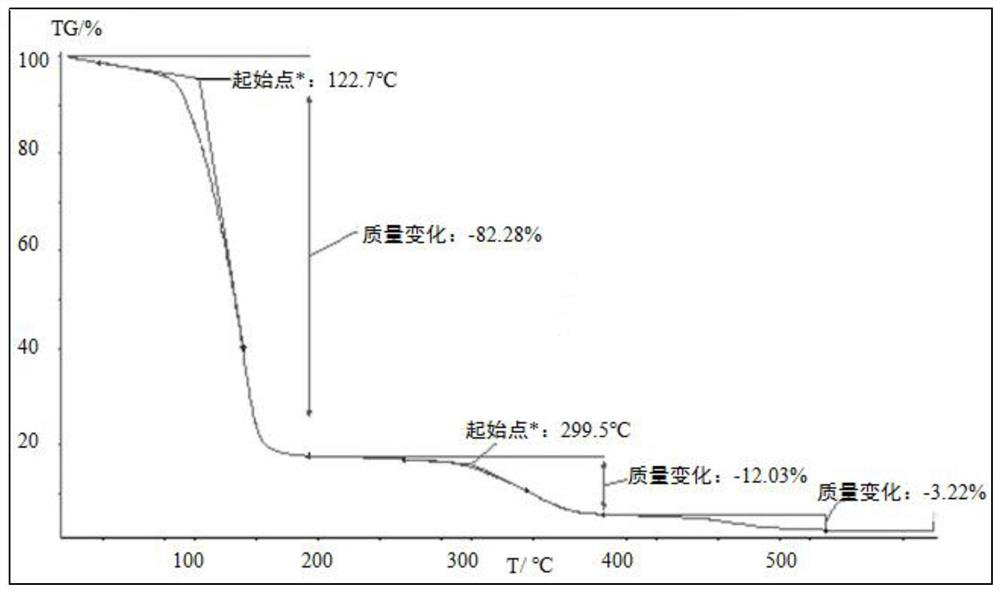

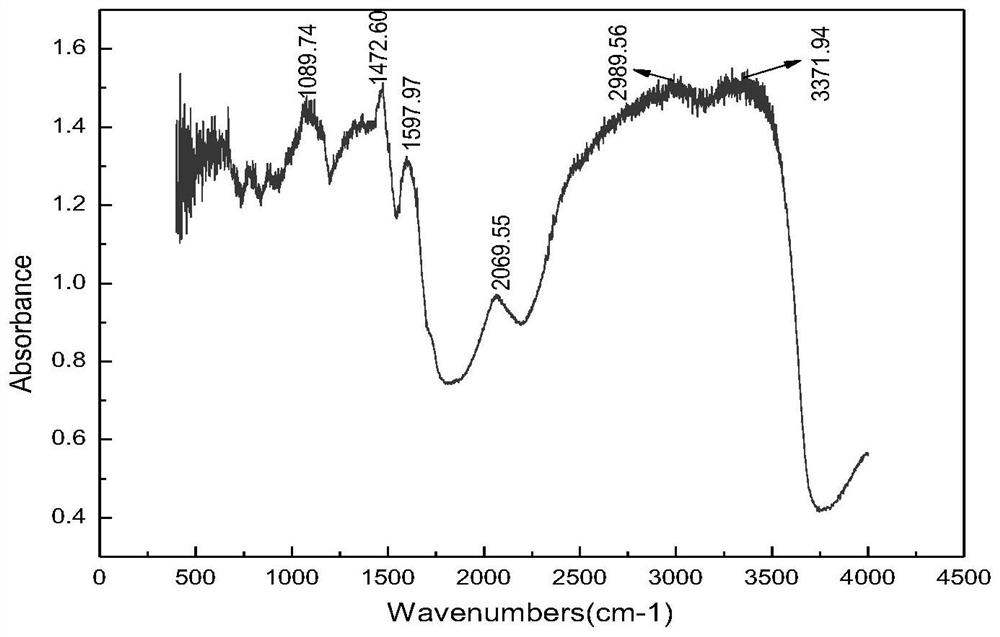

The invention relates to a preparation method of a high-temperature-resistant binary copolymerization low-molecular-weight polyamine inhibitor for water-based drilling fluid. It mainly solves the problems of poor temperature resistance and stability of the existing inhibitors. The preparation method of the inhibitor is composed of monomer A and monomer N-vinylpyrrolidone in a molar ratio of 1:2 to 1:10, under the action of metal catalysts such as sodium borohydride and Raney nickel, through catalytic hydrogenation The method is a low-molecular-weight polymer inhibitor synthesized by aqueous solution polymerization through multi-step reaction. The water-based drilling fluid uses a high-temperature resistant binary copolymer low-molecular-weight polyamine inhibitor, which has stronger temperature resistance and stability, can improve the inhibitory effect of the water-based drilling fluid on the shale formation, improve the stability of the well wall, and reduce downhole complex, promote the advancement of water-based drilling fluid technology and the smooth progress of oil and gas exploration.

Description

Preparation of high temperature resistant binary copolymer low molecular weight polyamine inhibitor for water-based drilling fluid backup method Technical field: The present invention relates to the technical field of synthetic preparation of water-soluble organic polymers for oil drilling, especially a kind of water-based The invention discloses a preparation method of high temperature resistant binary copolymer low molecular weight polyamine inhibitor for drilling fluid. Background technique: The instability of wellbore in mud shale formation is a technical problem that is often encountered in drilling engineering, and every year gives world oil Industry causes losses of at least about $600 million and consumes about 5% to 6% of the total drilling time. According to statistics It is shown that shale formations account for 70% of the total formations drilled, and more than 90% of the wellbore instability problems occur in shale formations. water sensitive Active...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/035

CPCC09K8/035

Inventor 刘永贵侯杰杨决算于兴东宋涛初成宋程周波

Owner DAQING PETROLEUM ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com