Polyamine inhibitor for water-based drilling fluid and preparation method thereof

A technology for water-based drilling fluid and polyamine inhibitor, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of shale inhibition effect and high temperature resistance performance not satisfactory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

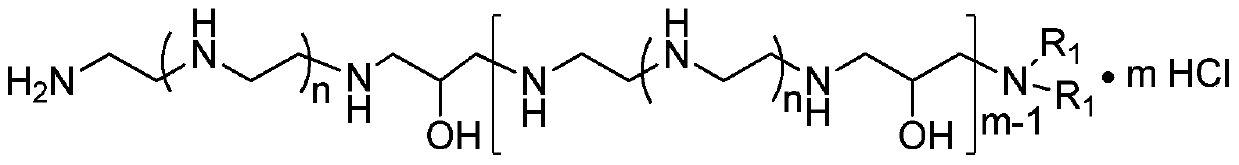

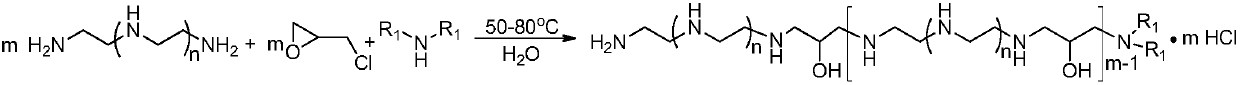

[0024] Add 6.01kg of ethylenediamine and 18kg of water into a double-layer glass reactor with a capacity of 50L and mix them. Slowly add 9.25kg of epichlorohydrin under stirring conditions. Heat is released during the reaction, and circulating cooling water is introduced into the interlayer. Control the reaction temperature not to exceed 80°C, add epichlorohydrin within 45 minutes, keep stirring, start heating when the temperature drops to 50°C, control the temperature, and the reaction temperature is 75-80°C, add 1.05kg diethanolamine after 2 hours of reaction, continue After reacting for 2 hours and cooling to room temperature, a light yellow viscous liquid was obtained, which was the polyamine inhibitor for the water-based drilling fluid. Gained polyamine inhibitor molecular structure simplified formula is as follows:

[0025]

Embodiment 2

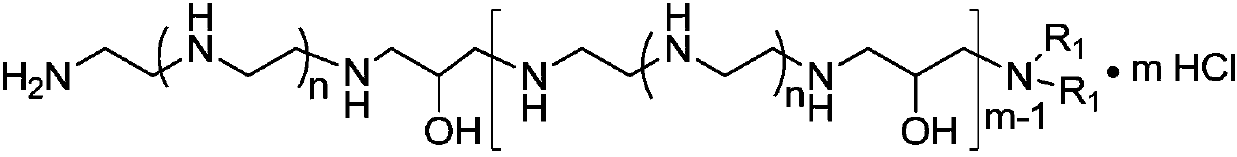

[0027] Add 7.31kg of triethylenetetramine and 14kg of water into a double-layer glass reactor with a capacity of 50L and mix them. Slowly add 4.63kg of epichlorohydrin under stirring conditions. Heat is released during the reaction, and circulating cooling water is introduced into the interlayer. , control the reaction temperature not to exceed 80°C, add epichlorohydrin within 30 minutes, keep stirring, and start heating when the temperature drops to 50°C, the temperature control reaction temperature is 70-73°C, add 0.50kg mass fraction after 3 hours of reaction 30% dimethylamine aqueous solution was continued to react for 1.8 h, and cooled to room temperature to obtain a light yellow viscous liquid, which was the polyamine inhibitor for the water-based drilling fluid. The molecular structure simplified formula of gained polyamine inhibitor is as follows:

[0028]

Embodiment 3

[0030] Add 9.45kg of tetraethylenepentamine and 20kg of water into a double-layer glass reactor with a capacity of 50L and mix them. Slowly add 4.63kg of epichlorohydrin under stirring conditions. Heat is released during the reaction, and circulating cooling water is introduced into the interlayer. , control the reaction temperature not to exceed 80°C, add epichlorohydrin within 35 minutes, keep stirring, start heating when the temperature drops to 50°C, control the temperature, the reaction temperature is 74-77°C, add 0.24kg of diethylamine after 2 hours of reaction , continue the reaction for 1.8h, and cool to room temperature to obtain a light yellow viscous liquid, which is the polyamine inhibitor for the water-based drilling fluid; the molecular structure of the polyamine inhibitor obtained is as follows:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com