KCl blocking and anti-sloughing drilling fluid and preparation method thereof

A technology of drilling fluid and coating inhibitor, which is applied in the field of petroleum drilling, can solve the problems of poor plugging ability and insufficient ability to inhibit water-sensitive collapse, and achieve good anti-collapse and meet the needs of safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

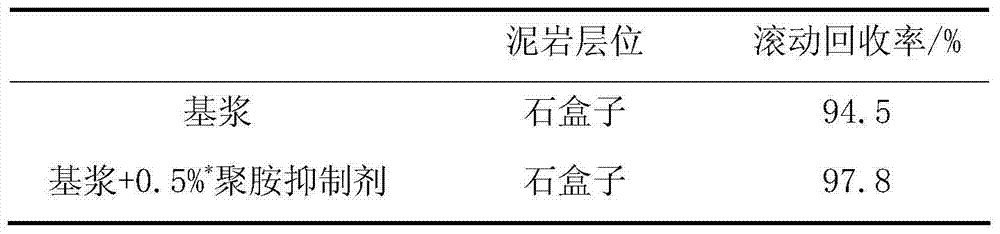

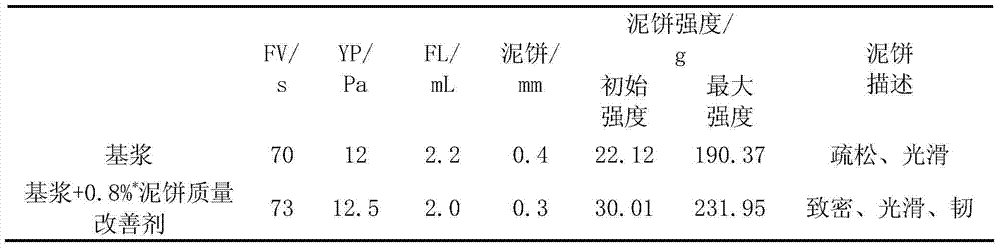

[0037] Prepare the drilling fluid according to the components of the following mass fractions, each component is added into the water by a shear pump, and the middle is supplemented with 75rpm stirring: add 0.1% Na 2 CO 3 , stirred for 6 minutes; added 3.2% bentonite, stirred for 30 hours; added 0.2% NaOH, stirred for 10 minutes; added 4% modified asphalt, 2.5% anti-salt fluid loss additive, 3% anti-high temperature fluid loss additive, 1.5% compound ammonium salt, stir for 15 minutes; add 0.3% polymer inhibitor, stir for 15 minutes; add 0.5% polyamine inhibitor, stir for 15 minutes; add 1% mud cake quality improver, stir for 15 minutes; add 8% KCL, stirred for 15 minutes; added 0.2% flow regulator, stirred for 15 minutes; added 3% anti-slump lubricant, 2% extreme pressure liquid lubricant, stirred for 10 minutes; added 2.5% high-efficiency anti-slump agent, stirred for 10 minutes ; Add 0.3% film-forming wall-solidifying agent and stir for 10 minutes to obtain drilling fluid....

Embodiment 2

[0039] Add the following mass fraction components into water with a shear pump under stirring at 70rpm: add 0.1% Na 2 CO 3 , stirred for 8 minutes; added 3.2% bentonite, stirred for 25 hours; added 0.2% NaOH, stirred for 10 minutes; added 4% modified asphalt, 2.5% anti-salt fluid loss additive, 3% anti-high temperature fluid loss additive, 1.5% compound ammonium salt, stir for 15 minutes; add 0.3% polymer inhibitor, stir for 15 minutes; add 0.5% polyamine inhibitor, stir for 15 minutes; add 0.8% mud cake quality improver, stir for 12 minutes; add 8% KCL, stirred for 15 minutes; added 0.2% flow regulator, stirred for 15 minutes; added 3% anti-slump lubricant, 2% extreme pressure liquid lubricant, stirred for 15 minutes; added 2.5% high-efficiency anti-slump agent, stirred for 10 minutes ; Add 0.3% film-forming wall-solidifying agent and stir for 10 minutes to obtain drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com