Preparation method of explosion-suppressing material

An anti-explosion and blank technology, which is applied in medical science, dentistry, dental drilling, etc., can solve the problems of lack of flexibility and extensibility, blockage of fuel tank oil passage, and collapse of anti-explosion materials, so as to prolong the service life and prevent blockage Oil circuit, good retardation and effect of heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

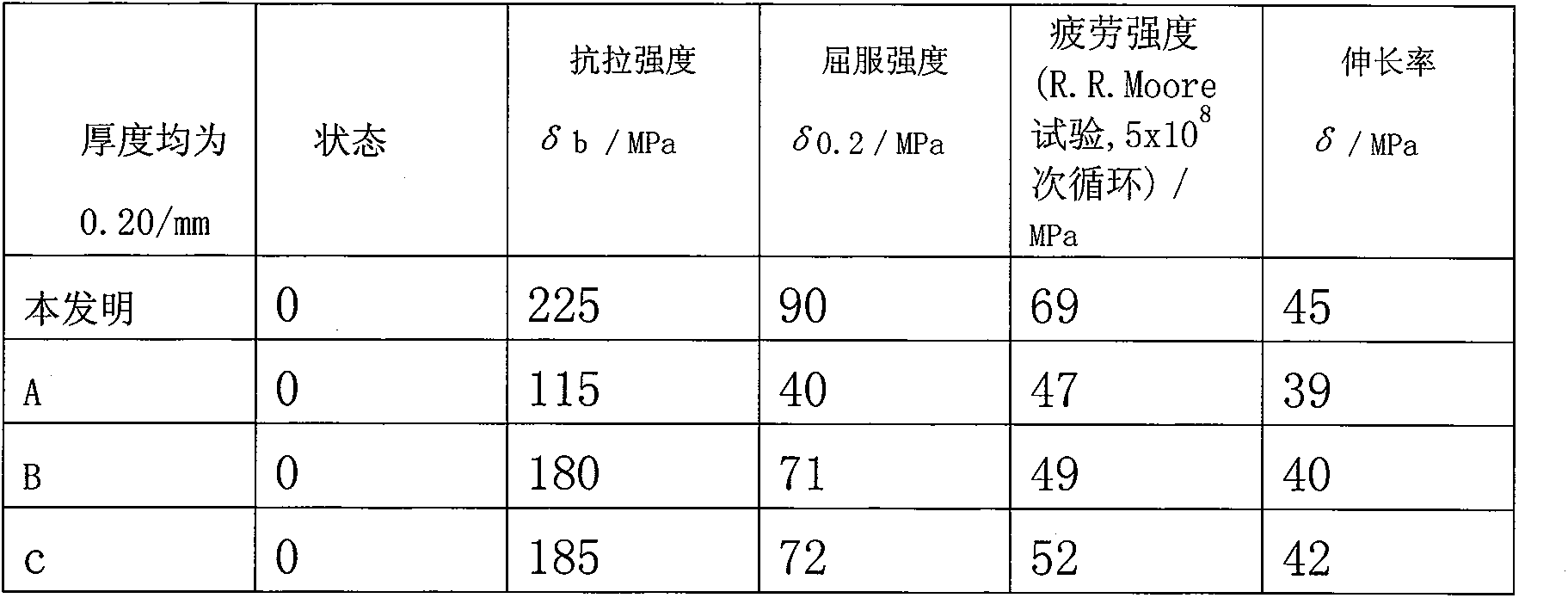

[0024] The chemical composition weight percentage of anti-explosion material of the present invention is Si0.3~0.5, Fe0.1~0.3, Cu0.15~0.25, Mn1.0~1.5, Mg1.0~1.5, Zn0.1~0.3, Ti0. 15~0.25, La0.03~0.06, Ce0.05~0.09, A1 balance. Among them, La and Ce are added in the form of mixed rare earth (La-Ce).

[0025] The weight percentage of the preferred component chemical composition is: the chemical composition weight percentage of the explosion suppression material is Si0.35~0.45, Fe0.15~0.2, Cu0.17~0.20, Mn1.1~1.3, Mg1.1~1.3 , Zn0.15~0.27, Ti0.19~0.22, La0.04~0.05, Ce0.06~0.08, A1 balance. Among them, La and Ce are added in the form of mixed rare earth (La-Ce).

[0026] The preparation method of the explosion-suppressing material of the present invention comprises putting the above-mentioned explosion-suppressing material of the chemical composition into a melting furnace and heating it at 730°C to 750°C to turn it into a liquid state, and the residence time of the liquid state is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com