Slide ball pin assembly suitable for heavy duty truck balance rear-pendant thrust rod

A sliding ball, rear suspension technology, applied in the direction of suspension, vehicle parts, cantilever mounted on the pivot, etc. Pin failure and other problems, to avoid easy failure, improve life and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

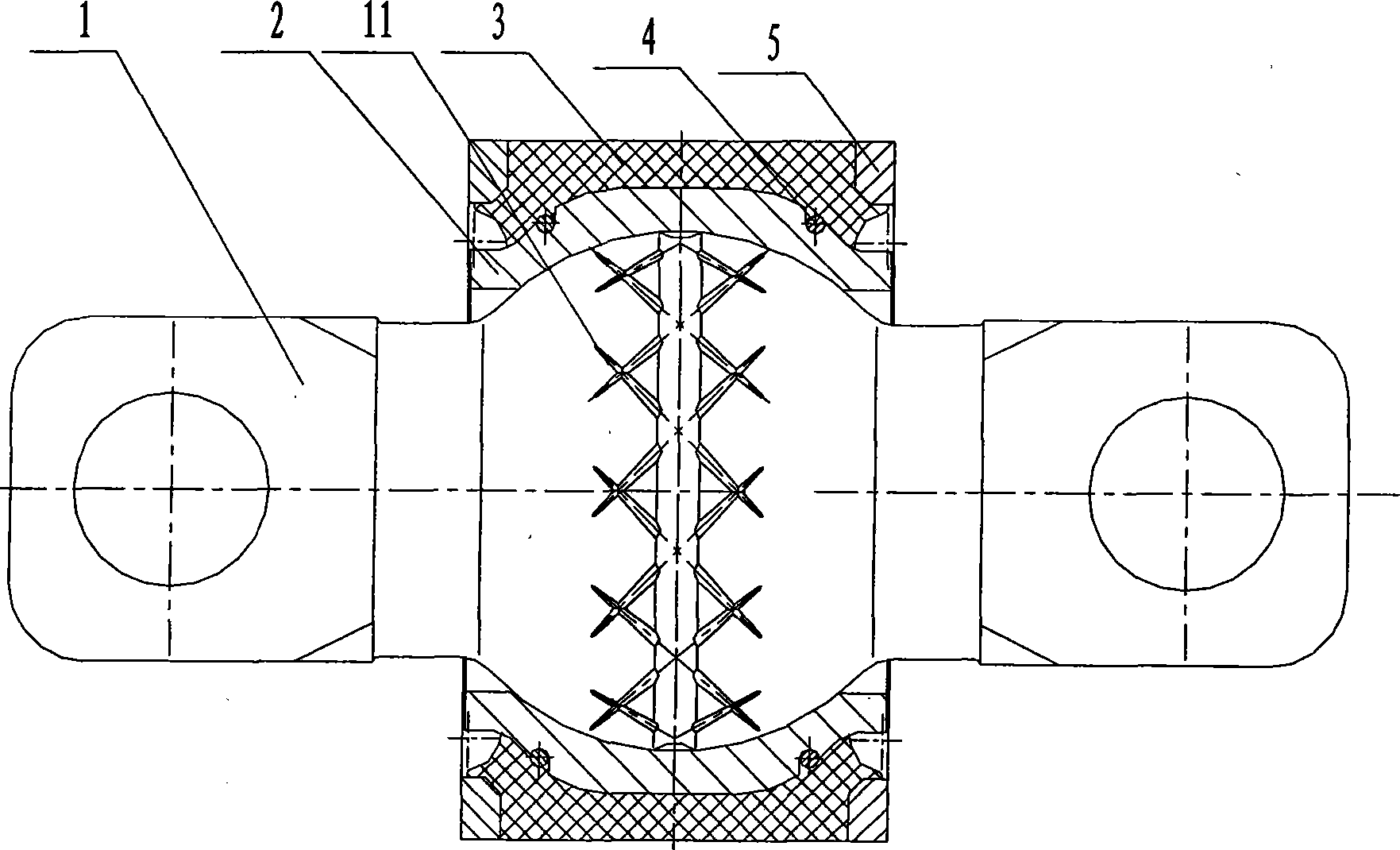

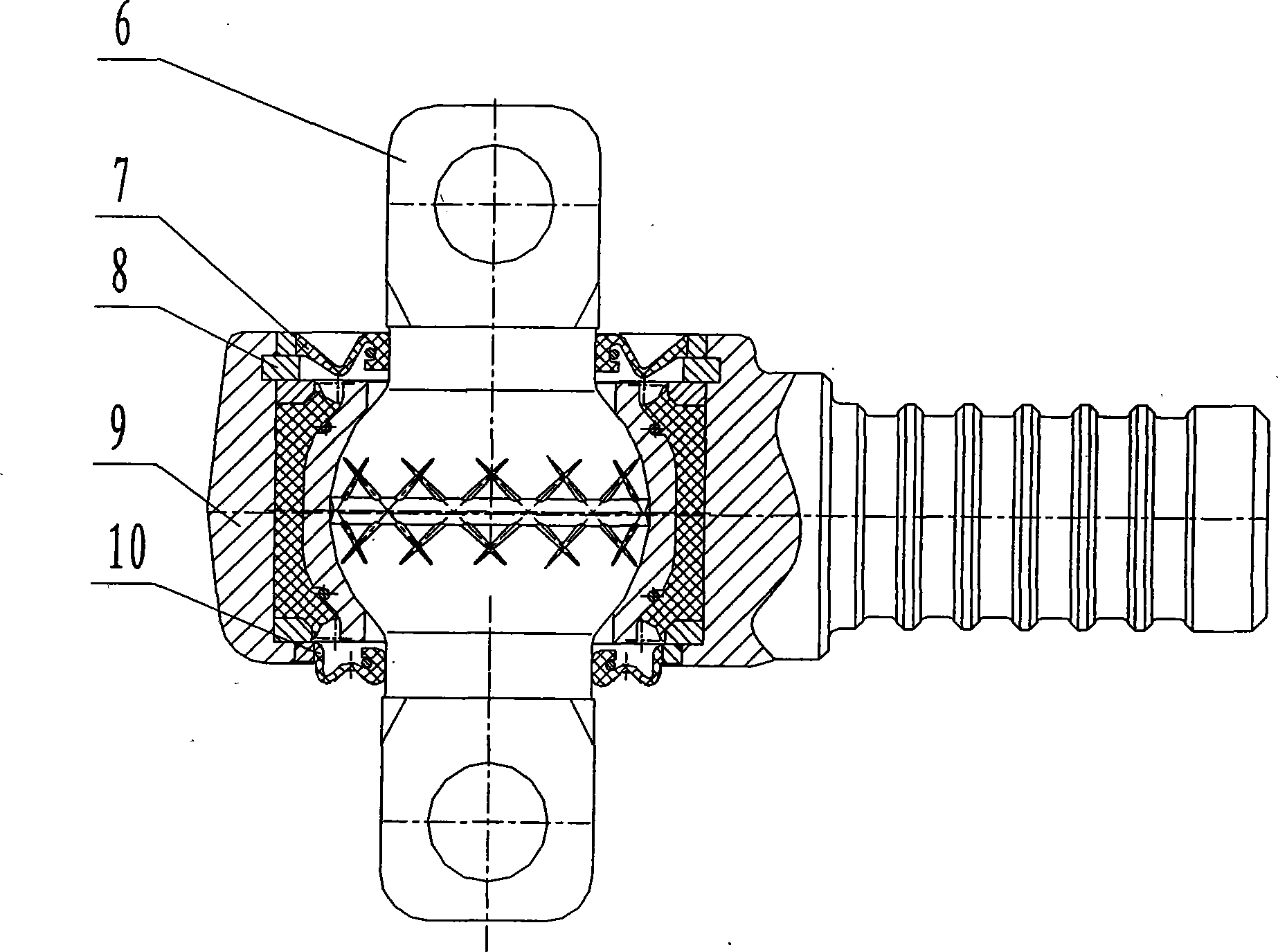

[0014] figure 1 , 2 Among them, the sliding ball pin assembly 6 includes a ball pin metal joint bearing and an end cover 5. The ball pin metal joint bearing includes a ball pin 1 and a friction pair outer ring 2. The middle part of the ball pin 1 is spherical, and the outside of the ball pin 1 is assembled There is a friction pair outer ring 2 that cooperates with it, and the two form a friction pair in the form of universal motion. The outer circumferential surface of the friction pair outer ring 2 is vulcanized with a layer of polyurethane 3, and the polyurethane 3 connects the friction pair outer ring 2 to the two ends. Cover 5 is vulcanized as one. The spherical surface of the ball pin 1 is provided with oil storage tanks 11 distributed in a cross pattern,

[0015] The outer ring 2 of the friction pair is a split structure, and the outer ring 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com