Expanding continuous-flow balloon catheter and preparation method thereof

A balloon and flow ball technology, which is applied in the direction of balloon catheter, dilator, surgery, etc., can solve the problems of pressure difference safety, affect the performance of the balloon, and be difficult to achieve, so as to achieve good pressure resistance and anti-corrosion. Improved extrusion performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

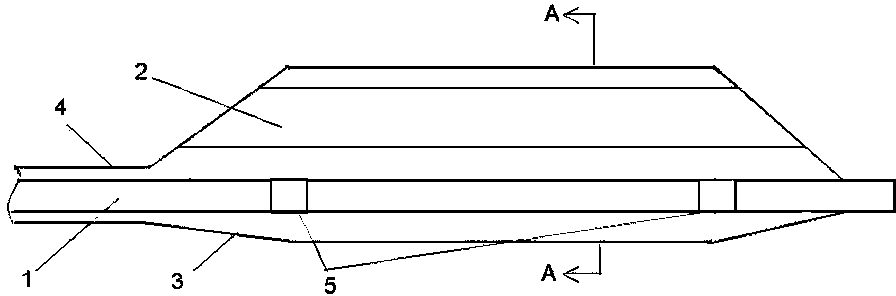

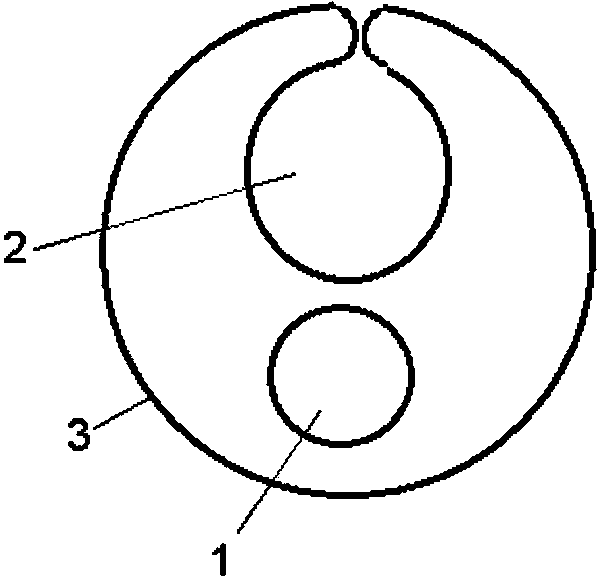

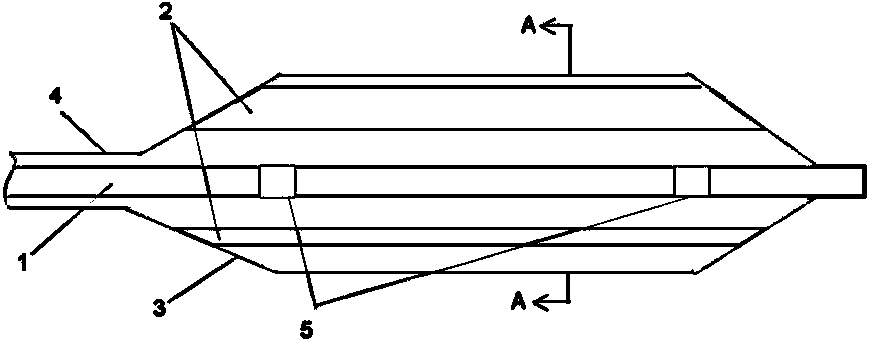

[0025] use as figure 1 , 2 The shape of the balloon shown in the mold is formed by pressurized heating and blow molding with a hollow tube, the forming pressure is 28bar, and the forming temperature is 50°C. The balloon 3 with two lobes on the edge is made. After the balloon 3 is filled, it is formed A hollow passage 2 . The cross-section of the hollow channel is round hole, oval hole or other irregular polygons. The balloon 3 is welded together with the outer catheter 4 and the inner catheter 1 equipped with the developing ring 5, and the inner catheter is arranged on one side of the balloon; the outer surface of the outer catheter is coated with a lubricating coating, and the surface of the balloon is coated with drugs . The hollow pipe used in this embodiment is a polyamide (nylon 12) pipe. The lubricious coating on the outer catheter is polyvinylpyrrolidone. The drug coated on the outer surface of the balloon is paclitaxel.

Embodiment 2

[0027] In this embodiment, as figure 1 , 2 The mold of the shape of the balloon shown is formed by pressurized heating blow molding with a hollow tube, the forming pressure is 38bar, and the forming temperature is 140°C. The hollow tube used is block polyetheramide. The lubricious coating on the outer catheter is polyethylene glycol. The drug coated on the outer surface of the balloon is rapamycin and its derivatives, and the rest are the same as in Example 1.

Embodiment 3

[0029] In this embodiment, as figure 1 , 2 The shape of the balloon shown in the mold is formed, and the hollow tube is pressurized and heated by blow molding. The forming pressure is 16bar, and the forming temperature is 200°C. The outer surface of the outer catheter is coated with a lubricating coating, and the surface of the balloon is coated with drugs. . The hollow pipe is polyethylene terephthalate (PET). The lubricating coating is polypropylene glycol. The drug coated on the outer surface of the balloon is resveratrol. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com