Preparation method of high-temperature-resistant binary copolymerized low-molecular-weight polyamine inhibitor for water-based drilling fluid

A technology of polyamine inhibitor and water-based drilling fluid, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and stability, achieve good inhibition performance and improve wellbore stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

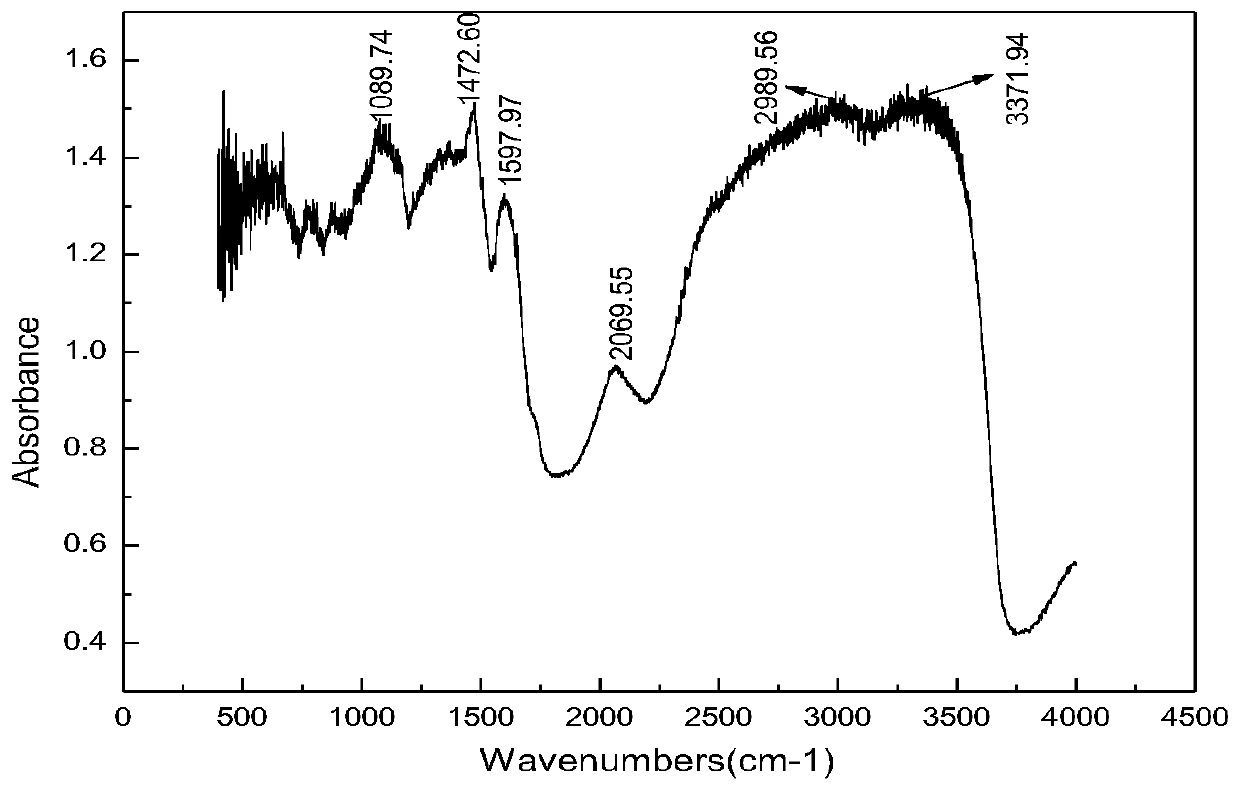

Image

Examples

Embodiment 1

[0022] Add divinyl glycol, NVP monomer and potassium persulfate (0.02% of the total amount of monomer) respectively in a high-temperature and high-pressure reactor at a molar ratio of 1:2, and stir and reflux at a temperature of 180-200°C After 2 to 3 hours; use sodium borohydride as catalyst, and under certain temperature and pressure conditions, adopt the method of catalytic hydrogenation to reduce all the carbonyl groups on divinyl glycol to hydroxyl groups; use palladium as catalyst, add to the calculation A good amount of ethylenediamine, feed high-purity hydrogen to stabilize the pressure between 2.6-3.2Mpa, raise the temperature to 220-240°C and keep it stable, react at high temperature for 4-5 hours under the condition of stirring, after cooling, filtering and other steps After that, can finally get containing multiple primary amines (-NH 2 ) group of amine-based inhibitor JY-2. The preparation reaction formula is as follows:

[0023]

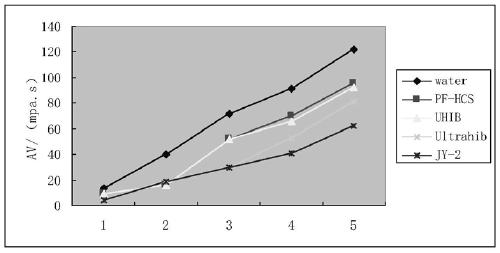

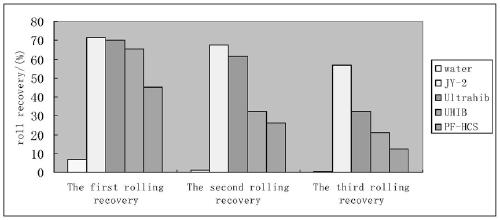

[0024] One, the inhibitor J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com