Polyamine composite salt water-based drilling fluid and preparation method thereof

A drilling fluid and compound salt technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of complex composition of rheological stabilizers, difficulty in exerting excellent performance, and inability to obtain molecular configurations, and achieve excellent thermal stability. Stability, excellent reliable inhibition, excellent rheological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

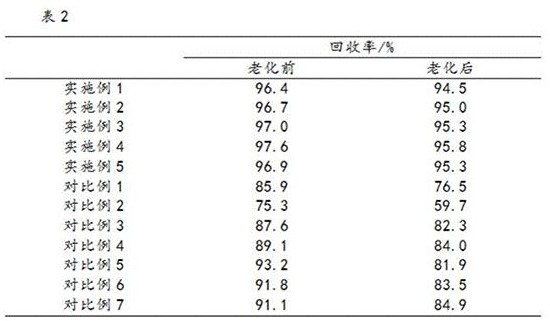

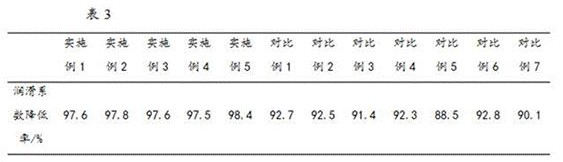

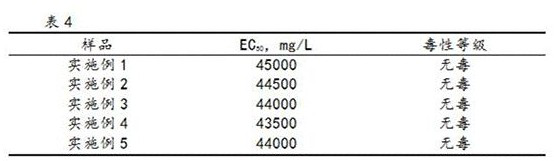

Examples

Embodiment 1

[0028] A polyamine composite brine-based drilling fluid, comprising the following components by weight: calcium formate 1%, sodium carbonate 1%, polyamine inhibitor 6%, pentaerythritol ricinoleate 2%, high polymer fluid loss reducer 1%, 3% sodium perfluorononenyloxybenzene sulfonate, 1% nonylphenol ethoxylate, 2% barite powder, and the balance of deionized water; the polyamine inhibitor comprises the following steps: Preparation method: Add amino cyclodextrin and maleic anhydride in a molar ratio of 2.5:6 into the reaction kettle and mix thoroughly, heat to 90-100 ° C, add glacial acetic acid, stir in vacuum for 6 hours, stop heating, and then add deionized water Continue to stir for 1 hour, cool and stand to obtain the polyamine inhibitor; the high polymer fluid loss reducer is a copolymer of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and acrylic acid.

[0029] Its preparation method comprises the following steps:

[0030] S1: weigh each component in proportion; ...

Embodiment 2

[0034] A polyamine composite brine-based drilling fluid, comprising the following components by weight: calcium formate 2%, sodium carbonate 2%, polyamine inhibitor 6%, pentaerythritol ricinoleate 2%, high polymer fluid loss reducer 1%, 3% sodium perfluorononenyloxybenzene sulfonate, 1% nonylphenol ethoxylate, 2% barite powder, and the balance of deionized water; the polyamine inhibitor comprises the following steps: Preparation method: Add amino cyclodextrin and maleic anhydride in a molar ratio of 2.5:6 into the reaction kettle and mix thoroughly, heat to 90-100 ° C, add glacial acetic acid, stir in vacuum for 6 hours, stop heating, and then add deionized water Continue to stir for 1 hour, cool and stand to obtain the polyamine inhibitor; the high polymer fluid loss reducer is a copolymer of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and acrylic acid.

[0035] Its preparation method comprises the following steps:

[0036] S1: weigh each component in proportion; ...

Embodiment 3

[0040] A polyamine composite brine-based drilling fluid, comprising the following components by weight: calcium formate 2%, sodium carbonate 2%, polyamine inhibitor 8%, pentaerythritol ricinoleate 5%, sodium nitrohumate 2% %, polymer fluid loss reducer 2%, sodium perfluorononenyloxybenzene sulfonate 5%, nonylphenol polyoxyethylene ether 2%, barite powder 3%, and the balance of deionized water; The polyamine inhibitor is prepared by a method comprising the following steps: adding aminocyclodextrin and maleic anhydride in a molar ratio of 2.5:6 into a reaction kettle and mixing thoroughly, heating to 90-100° C., adding glacial acetic acid, and vacuum stirring for reaction for 6 hours , stop heating, then add deionized water to continue stirring for 1h, cool and stand to obtain the polyamine inhibitor; the high polymer fluid loss control agent is 2-acrylamido-2-methylpropanesulfonic acid, Copolymer of acrylamide and acrylic acid.

[0041] Its preparation method comprises the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com