Environment-friendly type high-performance water-based drilling fluid and preparation method thereof

A water-based drilling fluid, high-performance technology, applied in the field of drilling fluid, can solve the problems of being unable to be widely used and high cost, and achieve the alleviation of the contradiction between inhibition and slurry mixing, good lubricity, excellent rheology and thixotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

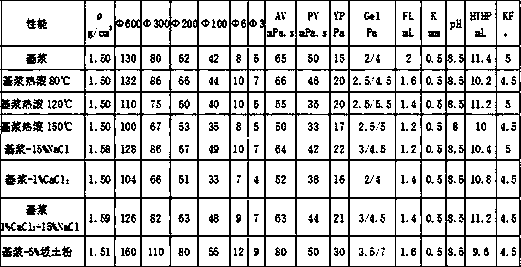

Image

Examples

Embodiment 1

[0023] Water and its components in parts by mass of water: 4% polyamine inhibitor, 17% compound formate, 0.8% polymer strong coating agent, 2% polymer fluid loss control agent, 0.8% compound ammonium Salt, 0.8% technical grade low viscosity carboxymethyl cellulose, 3% low fluorescent white asphalt, 0.5% biopolymer, 6% vegetable oil lubricant, 4% light calcium, 2% heavy calcium, 0.7% potassium hydroxide, heavy Crystal powder 120%;

[0024] Mix the above substances evenly by stirring.

Embodiment 2

[0026] Identical to embodiment 1 component and preparation method;

[0027] The polyamine inhibitor is an amino-terminated polyether with a molecular weight less than 1000;

[0028] The polymer strong coating agent is zwitterionic polymer strong coating agent emulsion YL-HP;

[0029] The compound ammonium salt is composed of hydrolyzed polyacrylonitrile ammonium salt as the main polymer, potassium polyacrylate, zwitterionic polymer fluid loss reducer, and polyacrylamide as auxiliary polymers;

[0030] The modified vegetable oil is obtained by settling waste vegetable oil for 24 hours, centrifuging to remove impurities, reacting with methanol and a catalyst at 90°C for 6 hours, adding non-ionic surfactant and high temperature resistant processor to modify after rectification.

[0031] The technical-grade low-viscosity carboxymethyl cellulose is prepared by reacting cotton fiber with sodium hydroxide to generate alkali cellulose, and then carrying out carboxymethylation with mo...

Embodiment 3

[0036] Water and components by mass parts of water: 2% bentonite slurry, 2% polyamine inhibitor, 12% compound formate, 0.5% polymer strong coating agent, 1% polymer fluid loss control agent, 0.5% compound ammonium salt, 0.5% technical grade low viscosity carboxymethyl cellulose, 2% low fluorescent white asphalt, 0.3% biopolymer, 4% vegetable oil lubricant, 2% light calcium, 1% heavy calcium, 0.5% Potassium hydroxide, barite powder 50%;

[0037] The bentonite slurry is put into water and mixed uniformly, and then left to stand for 8 hours to 24 hours, then the remaining substances are added, and the mixture is obtained by stirring and mixing uniformly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com