Anti-collapse drilling fluid for coal seams, and preparation method thereof

A drilling fluid and anti-collapse technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problems of poor applicability, achieve good rheology, wide application range of density, and inhibit plugging ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

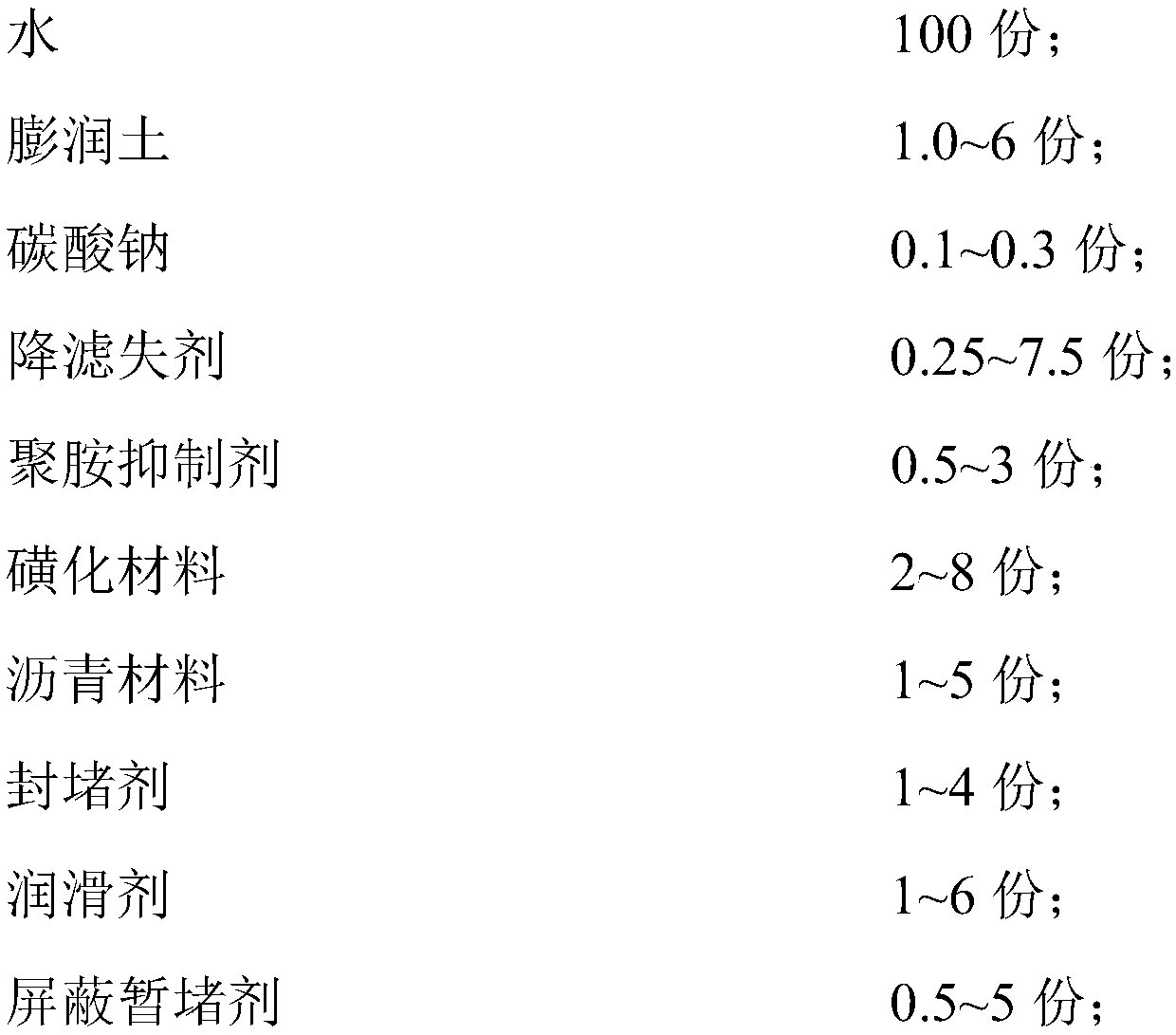

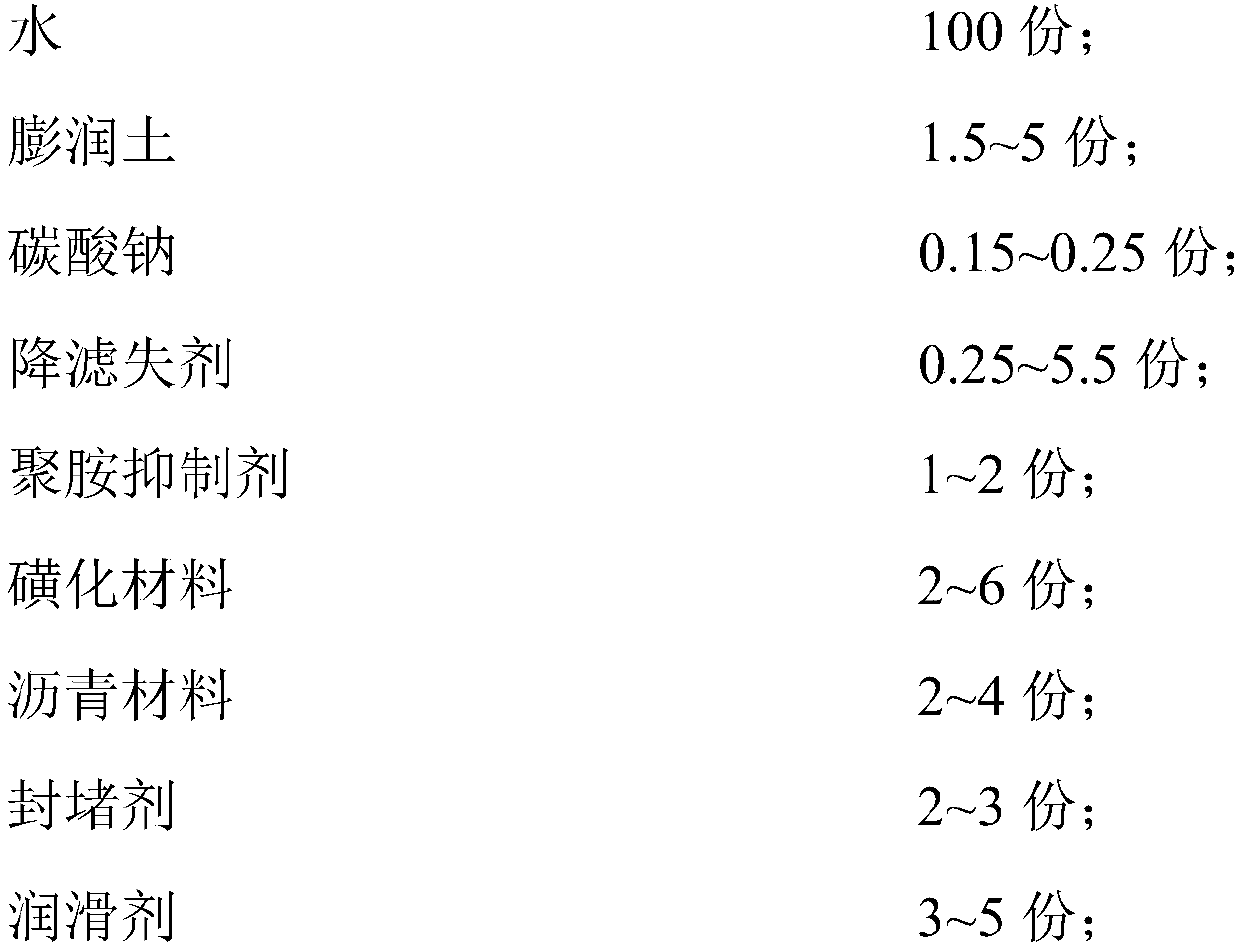

Method used

Image

Examples

Embodiment 1

[0040] The drilling fluid includes the following components: 100 parts of tap water, 4 parts of drilling fluid sodium bentonite, Na 2 CO 3 0.2 parts, SMPFL-L 0.75 parts, SMJA-1 1 part, sulfonated material (SMC 2 parts, SMP-2 2 parts, SPNH 2 parts), FF-III 3 parts, SMGF-1 2 parts, SMNR-1 2 parts parts, 2 parts of SMPB-1, 11.5 parts of SMJH-1, some sodium hydroxide and barite.

[0041] The simplified drilling fluid treatment agent of the present embodiment is prepared by the following method:

[0042] Add 0.2 parts of Na to 100 parts of tap water 2 CO 3 After dissolving, add 4 parts of drilling fluid sodium-based bentonite and maintain for 24 hours, then add 0.75 parts of SMPFL-L, 2 parts of SMC, 2 parts of SMP-2, 2 parts of SPNH, 3 parts of FF-III, 1 part of SMJA-1, 2 parts of SMGF-1, 2 parts of SMNR-1, 2 parts of SMPB-1, 1.5 parts of SMJH-1 and 67 parts of barite, after fully dispersed and uniform, adjust the pH of the drilling fluid with sodium hydroxide to 10. Drilling ...

Embodiment 2

[0048] The drilling fluid includes the following components: 100 parts of tap water, 2 parts of drilling fluid sodium bentonite, Na 2 CO 3 0.1 part, SMPFL-L 0.5 part, SMJA-1 1 part, sulfonated material (SMC 2 parts, SMP-3 3 parts, SPNH 2 parts), FF-III 1.5 parts, SMNA-1 3 parts, SMGF-1 2 parts 2 parts of SMNR-1, 1 part of SMPB-1, 1 part of SMJH-1, some sodium hydroxide and barite.

[0049] The simplified drilling fluid treatment agent of the present embodiment is prepared by the following method:

[0050] Add 0.1 part of Na to 100 parts of tap water 2 CO 3 After dissolving, add 2 parts of drilling fluid sodium-based bentonite and maintain for 24 hours, then add 0.5 parts of SMPFL-L, 2 parts of SMC, 3 parts of SMP-3, 2 parts of SPNH, 1.5 parts of FF-III, 3 parts of SMNA-1, 1 part of SMJA-1, 2 parts of SMGF-1, 2 parts of SMNR-1, 1 part of SMPB-1, 1 part of SMJH-1 and 178 parts of barite, fully dispersed and evenly oxidized with hydrogen Sodium adjusts the pH of the drillin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com