Water-based nano drilling fluid and preparation method thereof

A kind of drilling fluid and nanotechnology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of oil-based and synthetic-based drilling fluid cost and environmental protection restrictions, serious environmental pollution, complicated treatment process, etc., to achieve saving The effect of total drilling cost, simplicity of cuttings disposal, and application safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

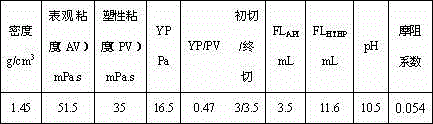

Embodiment 1

[0071] One, the water-based nano-drilling fluid of the present embodiment consists of the following components dispersed in water:

[0072] Base pulp,

[0073] Polyamine inhibitor, accounting for 3% of the volume of water-based nano drilling fluid,

[0074] Plugging agent, accounting for 2% of the mass of water-based nano-drilling fluid,

[0075] Deformable plugging polymer, accounting for 3% of the mass of water-based nano drilling fluid,

[0076] Lubricant, accounting for 2% of the volume of water-based nano-drilling fluid;

[0077] Wherein, the base slurry includes the following components:

[0078] Bentonite, accounting for 2% of the mass of water-based nano drilling fluid,

[0079] Sodium carbonate, accounting for 0.1% of the mass of water-based nano drilling fluid,

[0080] Sodium hydroxide, accounting for 0.1% of the mass of water-based nano drilling fluid,

[0081] Low-viscosity anionic cellulose, accounting for 1% of the mass of water-based nano-drilling fluid, ...

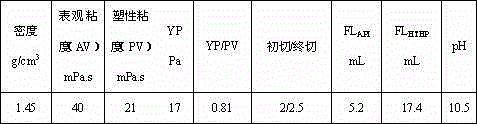

Embodiment 2

[0115] One, the water-based nano-drilling fluid of the present embodiment consists of the following components dispersed in water:

[0116] Base pulp,

[0117] Polyamine inhibitor, 0.5 % by volume of water-based nano drilling fluid,

[0118] Plugging agent, accounting for 0.5% of the mass of water-based nano drilling fluid,

[0119] Deformable plugging polymer AQUALSEAL, 0.5 % by mass of water-based nano-drilling fluid,

[0120] Lubricant, accounting for 0.5% of the volume of water-based nano-drilling fluid;

[0121] Wherein, the base slurry includes the following components:

[0122] Bentonite, accounting for 2% of the mass of water-based nano drilling fluid,

[0123] Sodium carbonate, accounting for 0.1% of the mass of water-based nano drilling fluid,

[0124] Sodium hydroxide, accounting for 0.1% of the mass of water-based nano drilling fluid,

[0125] Low-viscosity polyanionic cellulose, accounting for 1% of the water-based nano-drilling fluid mass,

[0126] Xanthan...

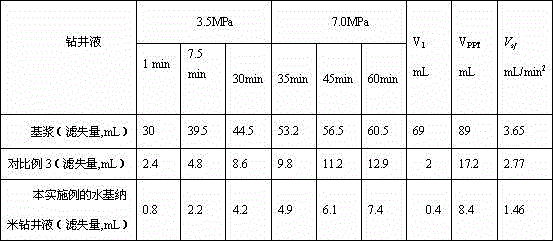

Embodiment 3

[0143] One, the water-based nano-drilling fluid of the present embodiment consists of the following components dispersed in water:

[0144] Base pulp, same as above

[0145] Polyamine inhibitor, accounting for 1.75% of the volume of water-based nano drilling fluid,

[0146] Plugging agent, accounting for 1.25% of the mass of water-based nano-drilling fluid,

[0147] The deformable plugging polymer AQUALSEAL accounts for 1.75% of the mass of water-based nano-drilling fluid,

[0148] Lubricant, accounting for 1.25% of the volume of water-based nano-drilling fluid;

[0149] Wherein, the base slurry includes the following ingredients:

[0150] Bentonite, accounting for 2% of the mass of water-based nano drilling fluid,

[0151] Sodium carbonate, accounting for 0.1% of the mass of water-based nano drilling fluid,

[0152] Sodium hydroxide, accounting for 0.1% of the mass of water-based nano drilling fluid,

[0153] Low-viscosity polyanionic cellulose, accounting for 1% of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com