Deep water riser buoyance block closed-loop control system

A deepwater riser and closed-loop control technology, which is applied in the automatic control system of drilling, drilling equipment, and mineral mining, etc., can solve the problems of increasing the accumulation of fatigue damage of the riser, large deformation of the riser, and the decrease of strength and buoyancy efficiency. Reduce water flow excitation and eddy current induced vibration, relieve stress concentration effect, and reduce dynamic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

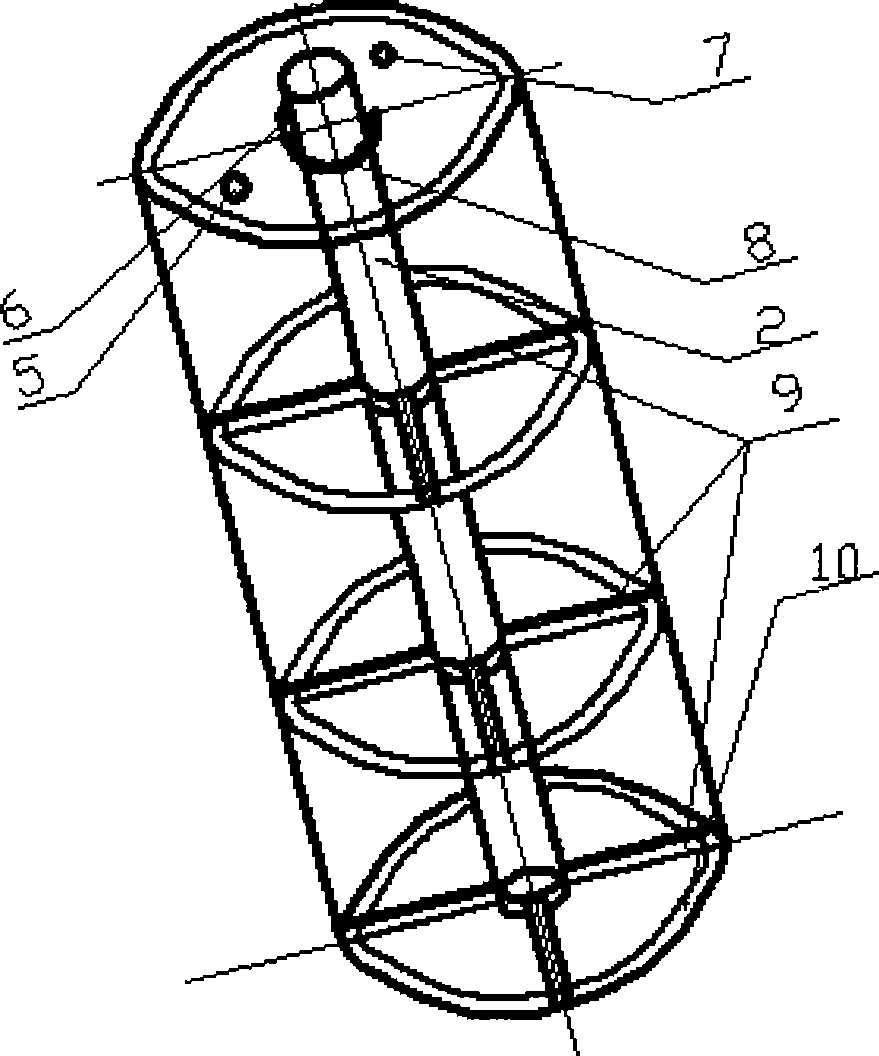

[0017] The details and work flow of the deepwater riser buoyancy block closed-loop control system proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

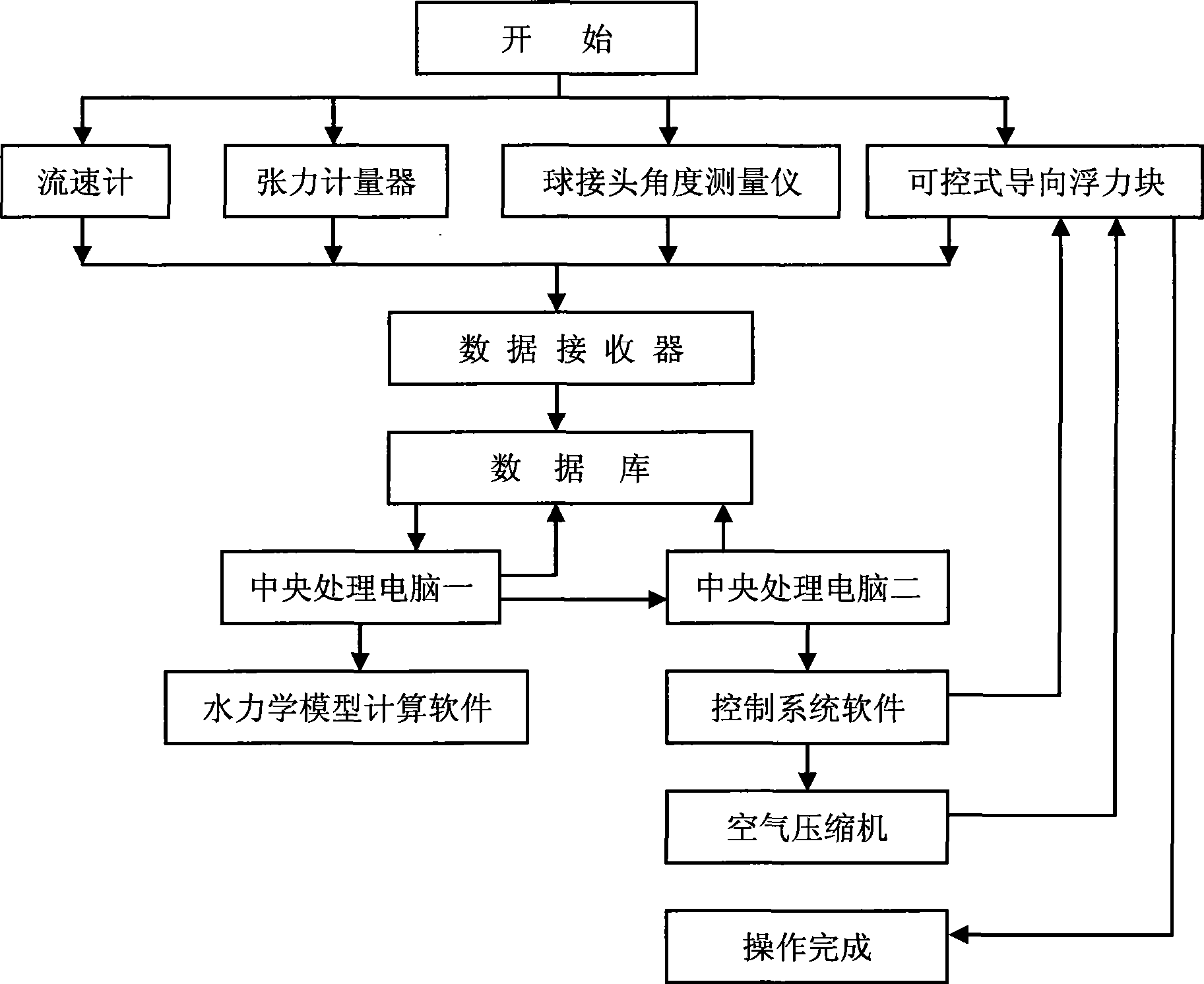

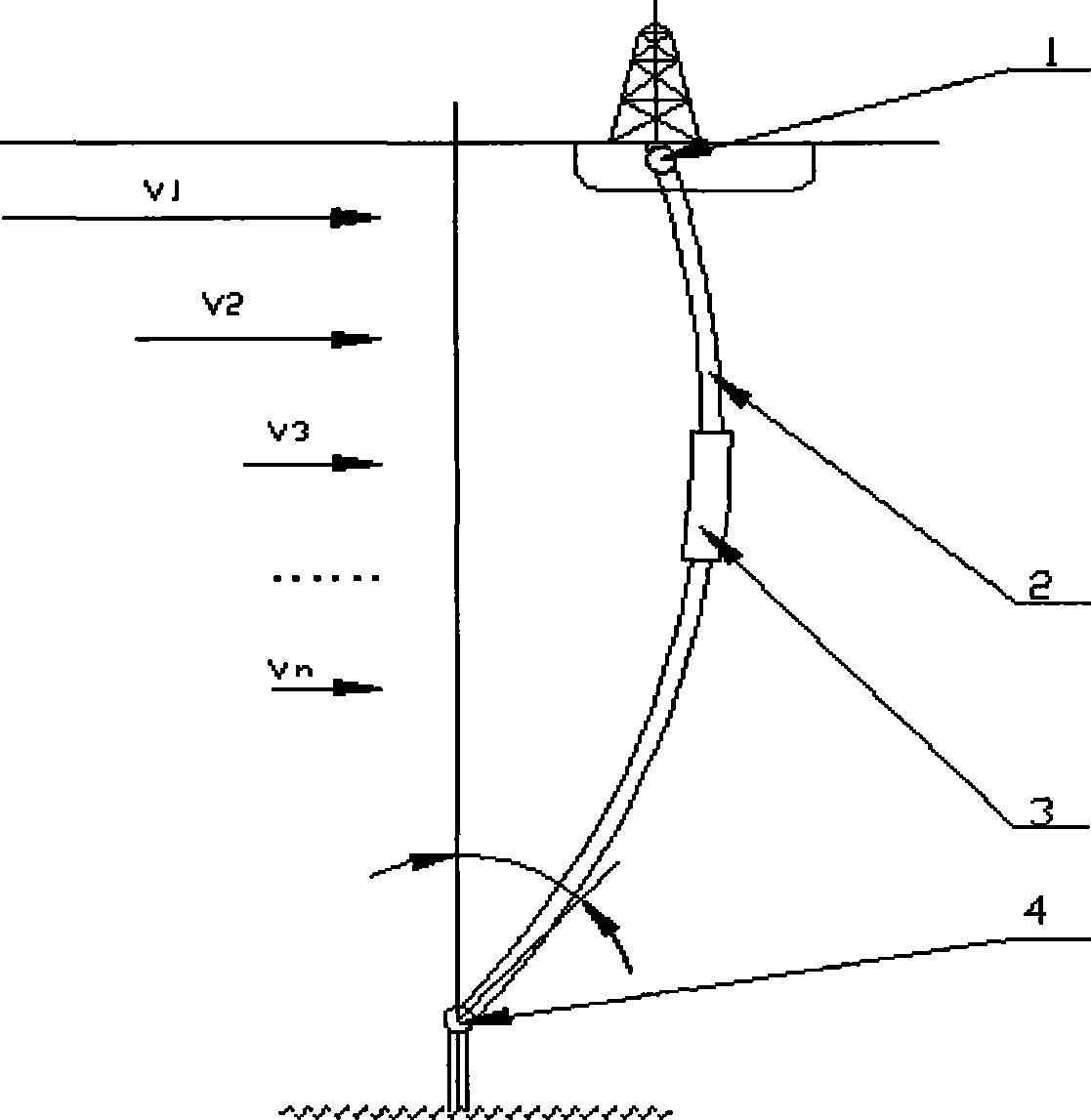

[0018] figure 1 , figure 2 Among them, the data receiver is connected with the current meter, the tensiometer, the controllable guide buoyancy block (3), and the ball joint angle measuring instrument, the data receiver is connected with the database, and the database is connected with the central processing computer. 1. Hydraulic model calculation software, Central processing computer 2. The control system software interacts with each other, and the control system software is connected with the air compressor and the controllable guide buoyancy block (3). System operation, current meter, tensiometer, controllable guide buoyancy block (3), ball joint angle measuring instrument to detect sea conditions and riser (2), upper ball joint (1), lower ball joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com