Feeding-in tool for surface guide tube during deepwater drilling

A deepwater drilling and feeding tool technology, applied in the field of offshore oil and gas drilling, can solve the problems of high operating costs, non-disclosure of process technology and sales of product tools, confidentiality of key parts and core data, etc., to prevent accumulation and rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

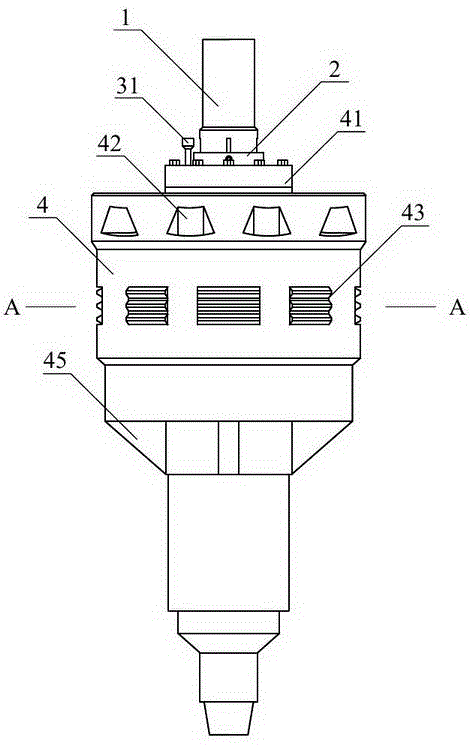

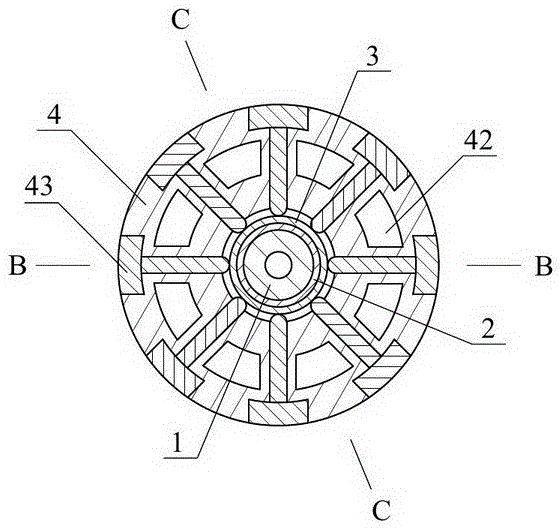

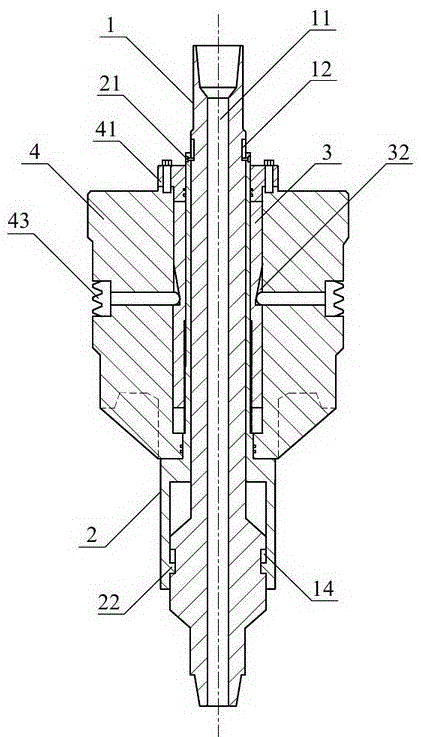

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the deep-water drilling surface conduit delivery tool includes: a mandrel 1, an inner sleeve 2, an outer sleeve 3, and a body 4; wherein: an inner sleeve 2, an outer sleeve 3, and a body 4. The inner sleeve 2 can slide up and down relative to the mandrel 1 and cannot rotate. The outer sleeve 3 and the inner sleeve are connected by a transmission thread pair, and the body 4 is located on the inner sleeve 2; the anti-rotation pin 44 runs through the body 4, The outer sleeve 3 is such that the outer sleeve 3 can only move up and down in the body 4 and cannot rotate.

[0020] The mandrel 1 is a hollow shaft, and the mandrel 1 is provided with a central hole 11, and the central hole 11 is a drilling fluid circulation channel; the upper end of the mandrel 1 is provided with an internal thread, and the mandrel 1 is connected with the upper drill pipe through the internal thread, and through the upper drill pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com