Deepwater drilling device based on near surface deviation

A deepwater drilling and drilling platform technology, which is applied in underwater drilling, earthwork drilling, wellbore/well components, etc. It can solve the problems that the ABS system cannot bear the flow rate, the system stability is not good, and the system requirements are high, so as to achieve improvement. Stability and adaptability, increased operating window, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

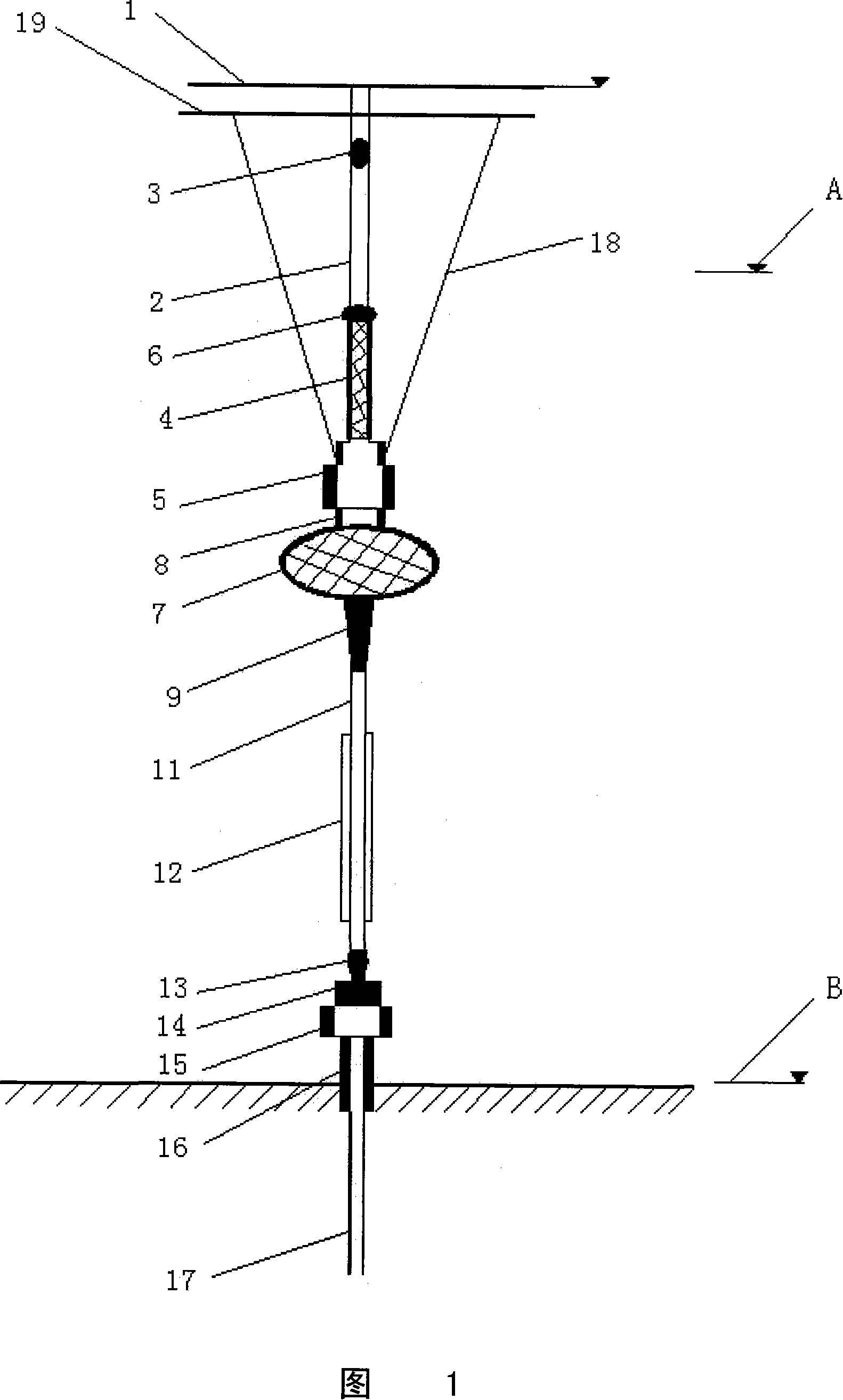

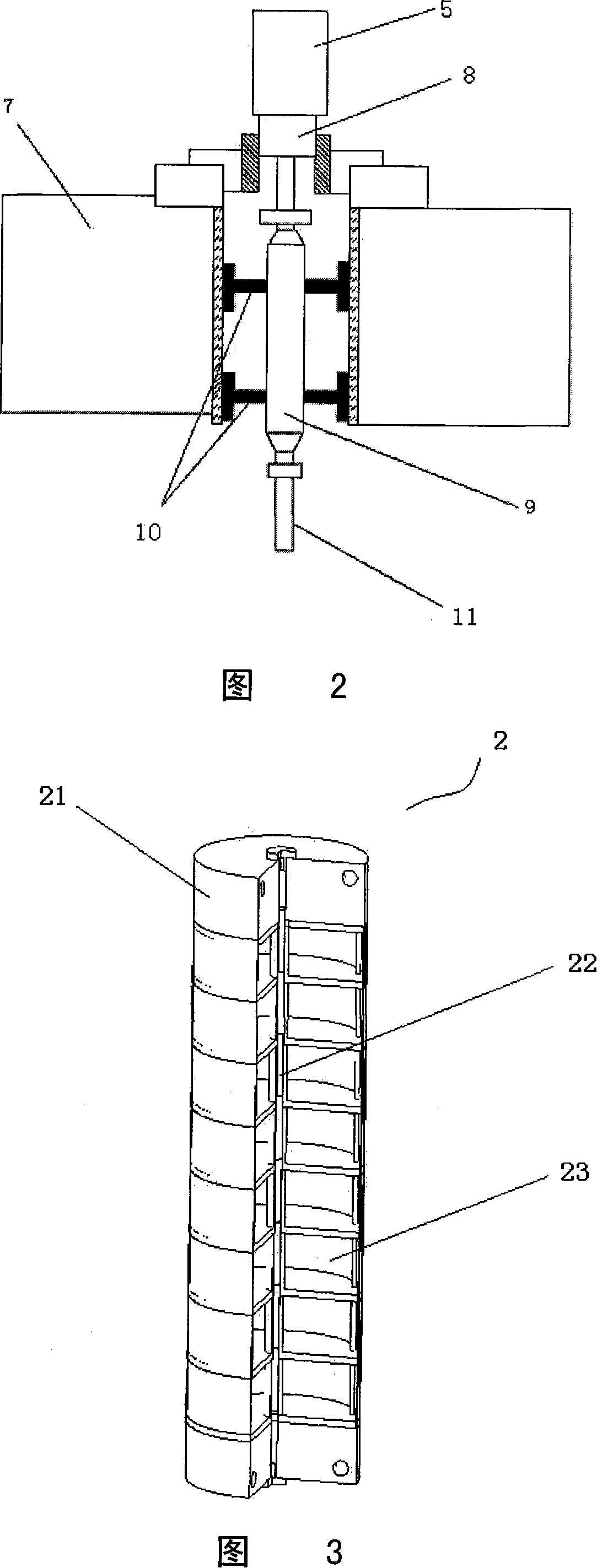

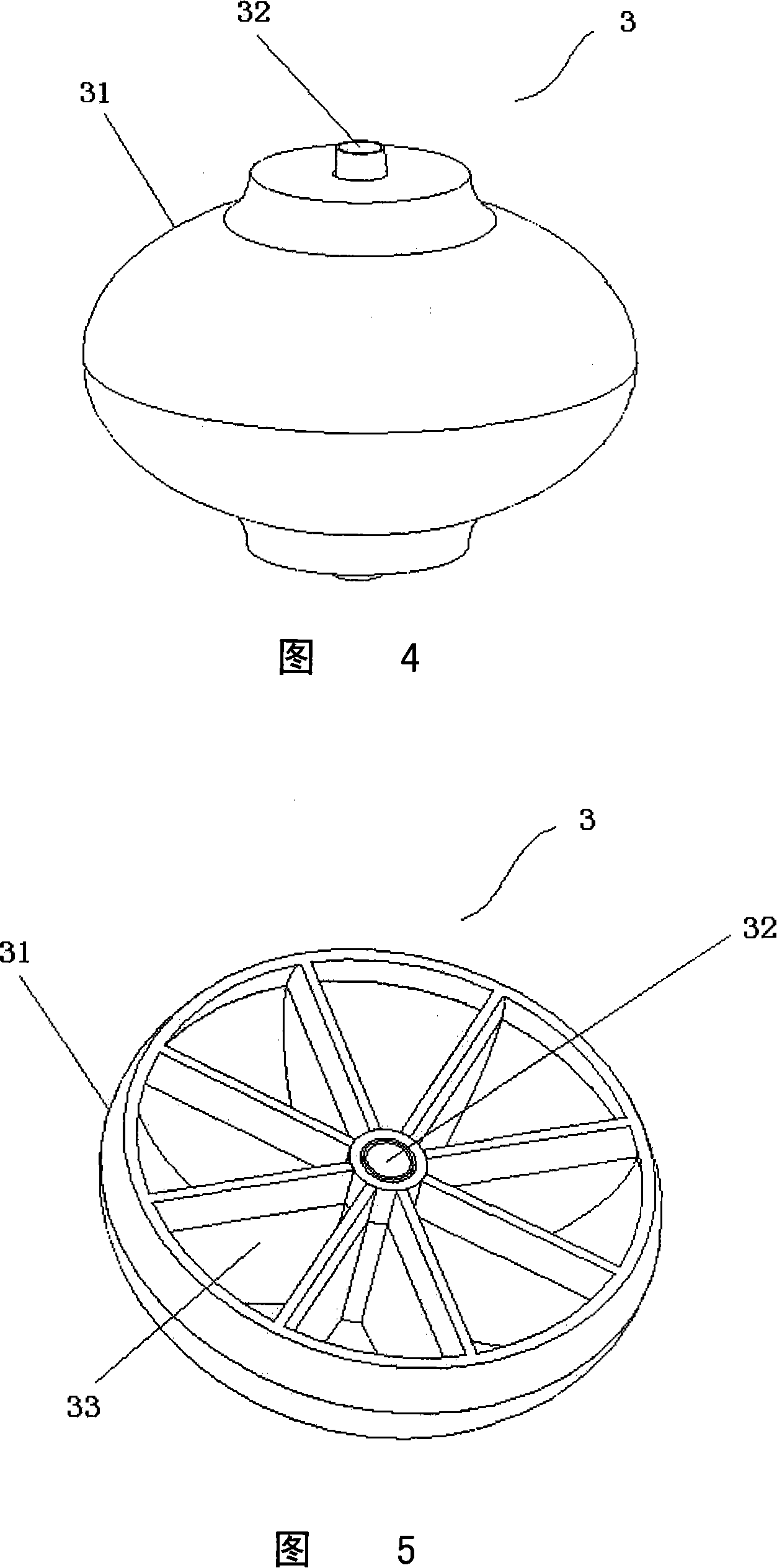

[0020] As shown in Fig. 1 and Fig. 2, the present invention includes a conventional riser 2 connected to the drilling platform 1, an upper flexible joint 3 is arranged in the middle of the riser 2, the riser 2 passes through a buoyancy chamber 4, and a blowout preventer The blowout preventer 5 is installed at a place 80-100m below the water surface A. The upper end of the buoyancy chamber 4 is provided with a disconnecting device 6 from the riser 2. A ballast tank 7 and an upper wellhead are provided below the blowout preventer 5. 8 is located between the blowout preventer 5 and the ballast tank 7 and sits and hangs in the central axis hole of the ballast tank 7 . The upper end of a stress joint 9 goes deep into the central shaft hole of the ballast tank 7 and is connected with the upper wellhead 8 , and a centralizer 10 is arranged between the stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com