Device and method for drilling by using full-automatic composite material continuous pipe

A technology of composite material and coiled tubing, which is applied in drilling drive devices, drilling equipment, and directional drilling in boreholes, and can solve the problems of unsuitable drilling fluids with high compression ratios, large restrictions on the type of screw motors, and shortened service life of coiled tubing, etc. problems, to achieve the effect of increasing controllability and flexibility, light weight, and reducing the number of trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

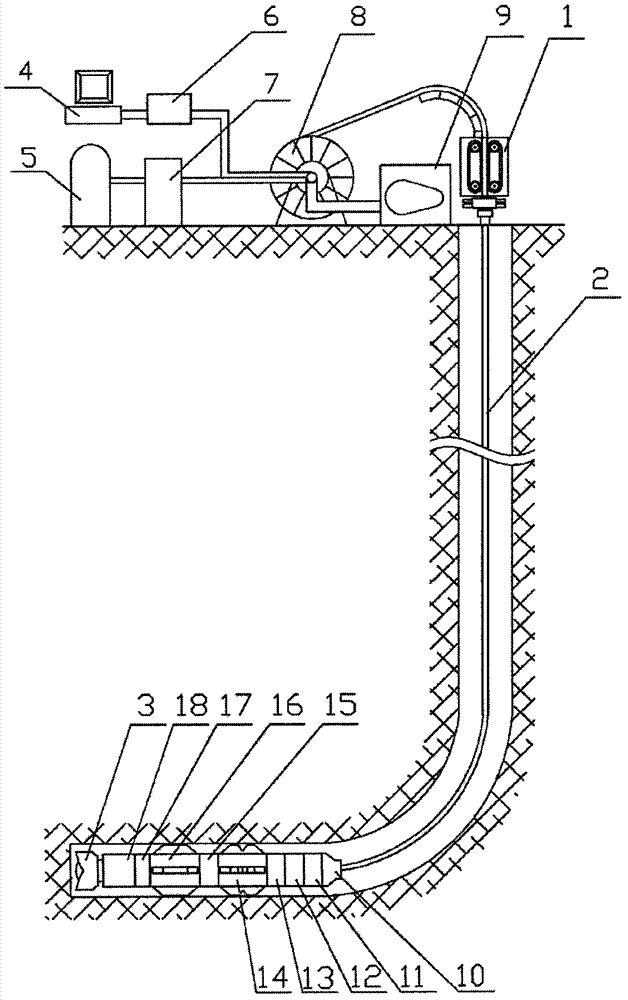

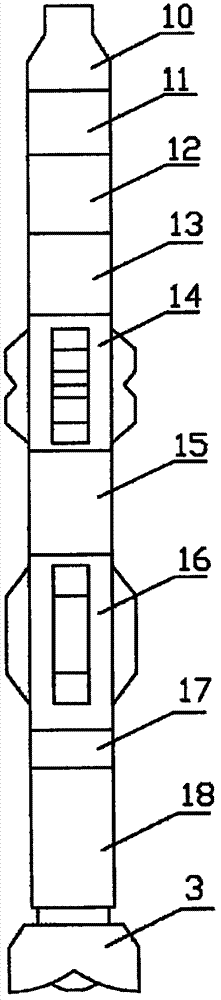

[0030] Refer to the attached figure 1 And attached figure 2 , the invention discloses an all-electric composite coiled tubing drilling device, the upper end of the drill bit 3 is connected to an electric motor 18 that drives the drill bit 3 to rotate, the invention includes a composite coiled tubing 2 embedded with cables, a coiled tubing drum 8, and a coiled tubing joint 10. A measuring mechanism 15 for measuring downhole parameters, and a steering tool 16 for changing the direction of the drill bit. The composite material coiled tubing 2 is provided with a mud flow channel, and the mud flow channel communicates with the nozzle of the drill bit 3 . The coiled tubing 2 of composite material is wound on the coiled tubing drum 8 , and the lower end of the coiled tubing 2 of composite material is connected with a coiled tubing joint 10 . The continuous pipe joint 10, the measuring mechanism 15, the guide tool 16 and the electric motor 18 are sequentially connected in series. ...

Embodiment 2

[0035] The invention discloses an all-electric composite coiled tubing drilling method:

[0036] In the first step, the coiled tubing 2 made of composite material is used to run the bottom hole assembly including the drill bit 3 , the electric motor 18 , the steering tool 16 , the measurement mechanism 15 and the electric control thruster 14 .

[0037] In the second step, the electric motor 18 is used to drive the drill bit 3 to rotate, and the electronically controlled thruster 14 is used to apply drilling pressure to the drill bit 3;

[0038] In the third step, in the underground, use the measuring mechanism 15 to collect data, and upload the measured data to the ground in real time; receive the control command transmitted from the ground, use the electric motor 18 to change the speed of the drill bit 3, use the guide tool 16 to change the direction of the drill bit 3, and use the electric motor 18 to change the direction of the drill bit 3. Control the thruster 14 to change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com