Asynchronous inducting type less-polarity-difference magnetic driving eccentric gear pair in transverse magnetic field

A technology of magnetic transmission and transverse magnetic field, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of permanent magnet magnetic flux reduction, influence on torque, consumption of magnetomotive force of rare earth permanent magnet, etc., and achieve energy loss Small size, increase unit moment density, and save the consumption of a single unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

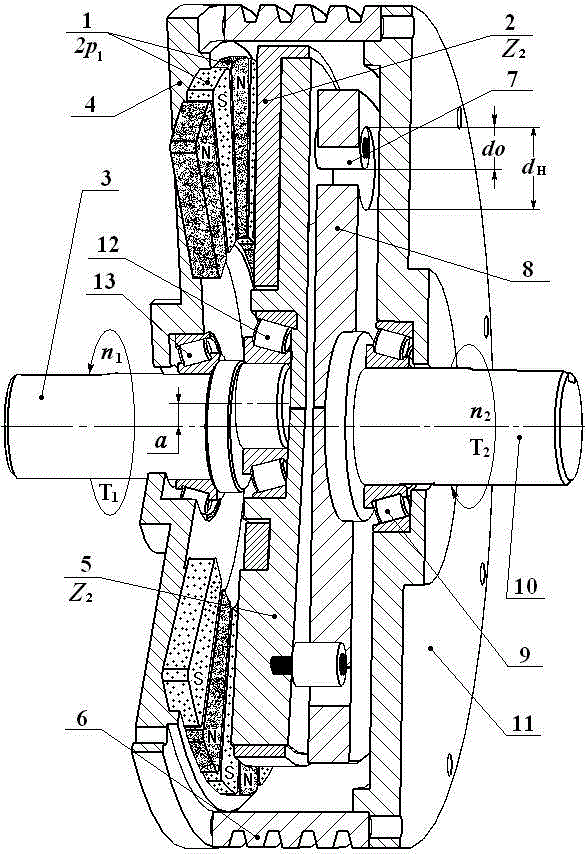

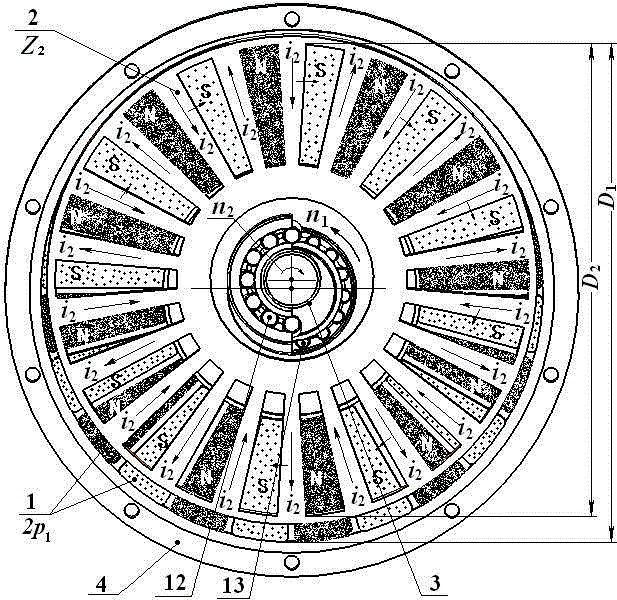

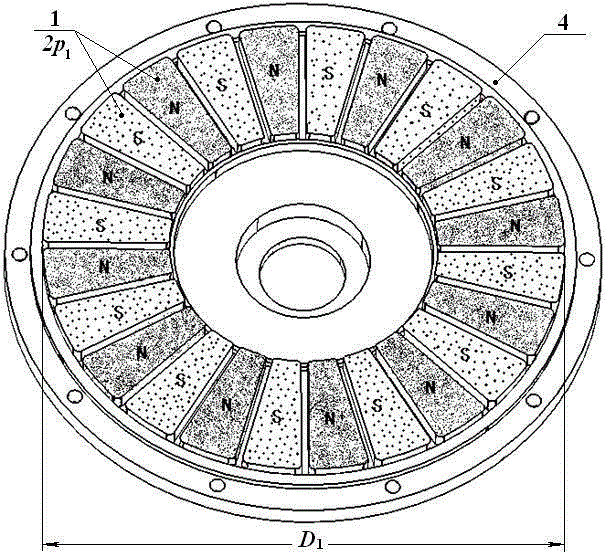

[0038] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described: figure 1 It is a full section view of the three-dimensional structure of the eccentric gear pair of the asynchronous induction type magnetic transmission with a transverse magnetic field, figure 2 It is a planar topological diagram of the working principle of the eccentric gear pair of the asynchronous induction type magnetic transmission with transverse magnetic field, image 3 It is a three-dimensional structure diagram of a large magnetic disk of an asynchronous induction type magnetic transmission eccentric gear pair with a transverse magnetic field, Figure 4 It is a composite cross-sectional view of the three-dimensional structure of the planetary disc of the asynchronous induction type magnetic transmission eccentric gear pair with transverse magnetic field.

[0039] One, from figure 2 It can be seen that the working principle of the asynchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com