Drill pipe straightening and anti-wear device for riser section in deepwater drilling

A deepwater drilling and riser technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of riser deformation, anti-wear sleeve accumulation, channel blockage, etc., achieve simple assembly and installation, eliminate contact friction, and simple structure And the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

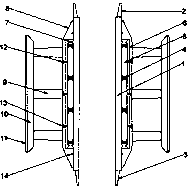

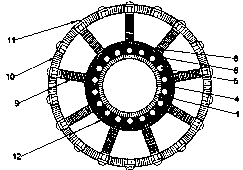

[0033] Such as Figure 1-6 As shown, a drill pipe straightening and anti-wear device for a deepwater drilling riser section includes a drill pipe connecting pipe 1, an internally threaded joint 2, an externally threaded joint 3, a roller support frame 4, a roller 5, and a roller restraint cylinder 6, A sealing ring 7, a protective shell 8, a support column 9, a support shell 10, a rubber strip 11, a screw 12, a screw anti-wear washer 13, and a locking ring 14. The two ends of the drill pipe connecting pipe 1 are respectively provided with internally threaded joints 2 and externally threaded joints 3 for connecting two upper and lower drill pipes, and the drill pipe connecting pipe 1 rotates with the drill pipe connecting pipe 1 . A roller support frame 4 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com