Little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of novel radial direction magnetic field

A magnetic transmission and radial magnetic field technology, applied in electromechanical transmissions, electric vehicles, electric components, etc., can solve the problems of large amount of expensive rare earth materials, reduction of magnetic flux of permanent magnets, consumption of rare earth permanent magnets, etc., and achieve dynamic instantaneous stability High, improve the unit torque density and power density, without the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

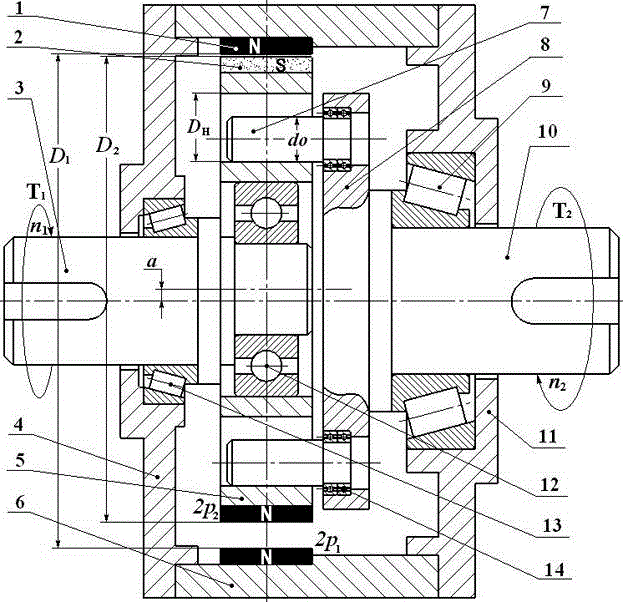

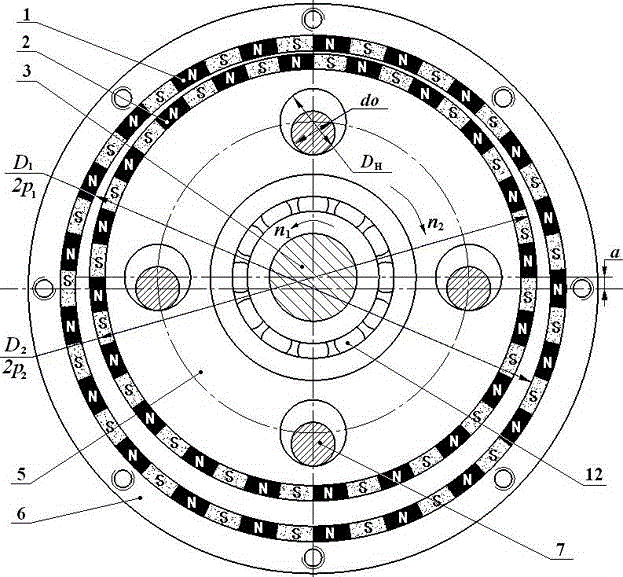

[0032] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described: figure 1 It is the full cross-sectional view of the axial structure of the eccentric gear pair of the magnetic transmission eccentric gear pair with few extreme differences in the radial magnetic field, figure 2 It is a radial structural full section view of the magnetically driven eccentric gear pair with few extreme differences in the radial magnetic field.

[0033] One, from figure 2 It can be seen that the working principle of the magnetic transmission eccentric gear pair with few polar differences in the radial magnetic field is: the eccentric input shaft 3 drives the planetary rotor core 5 to revolve around the axis of rotation, and the planetary rotor permanent magnet on the eccentrically revolving planetary rotor core 5 2 and the stator permanent magnet 1 drive the planetary rotor core 5 to reversely rotate around its own axis through magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com