Double-stator permanent magnet brushless doubly-fed wind generator

A wind turbine, permanent magnet brushless technology, applied in wind energy power generation, electrical components, electromechanical devices, etc., can solve problems such as reducing reliability, increasing maintenance workload, noise pollution maintenance workload, etc., to improve torque density and power density, reduce maintenance workload, and reduce the effect of maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

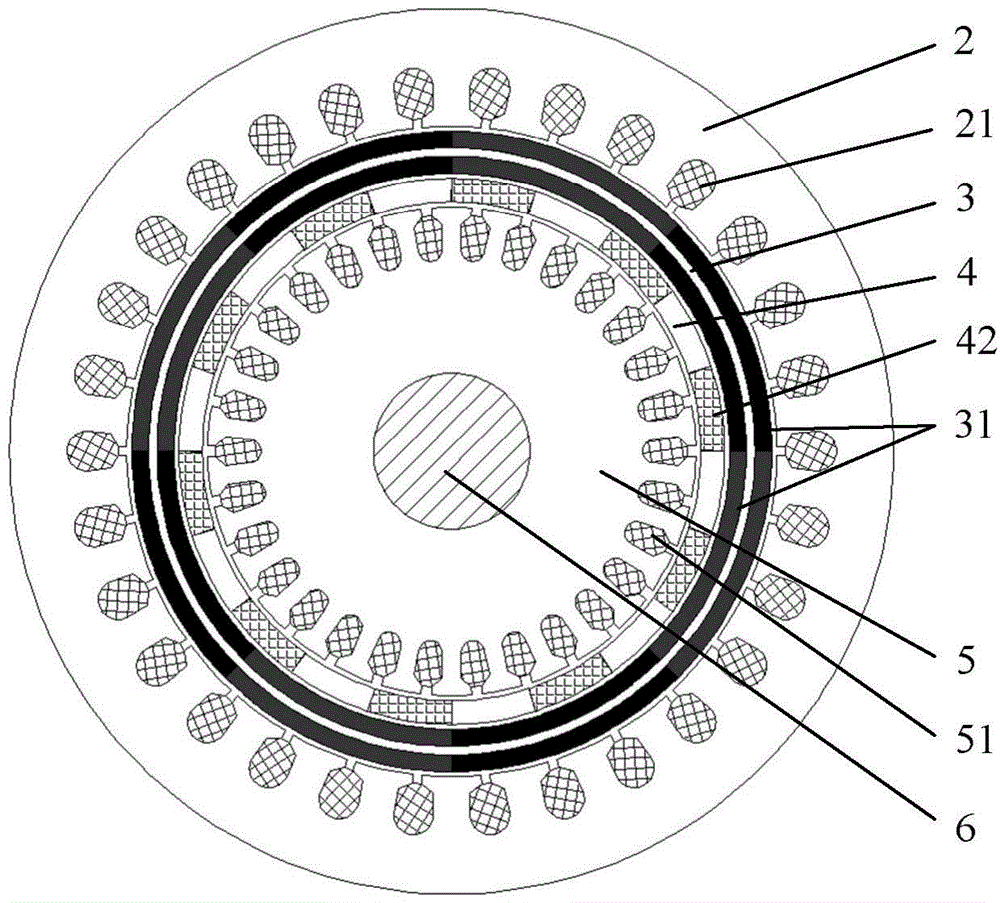

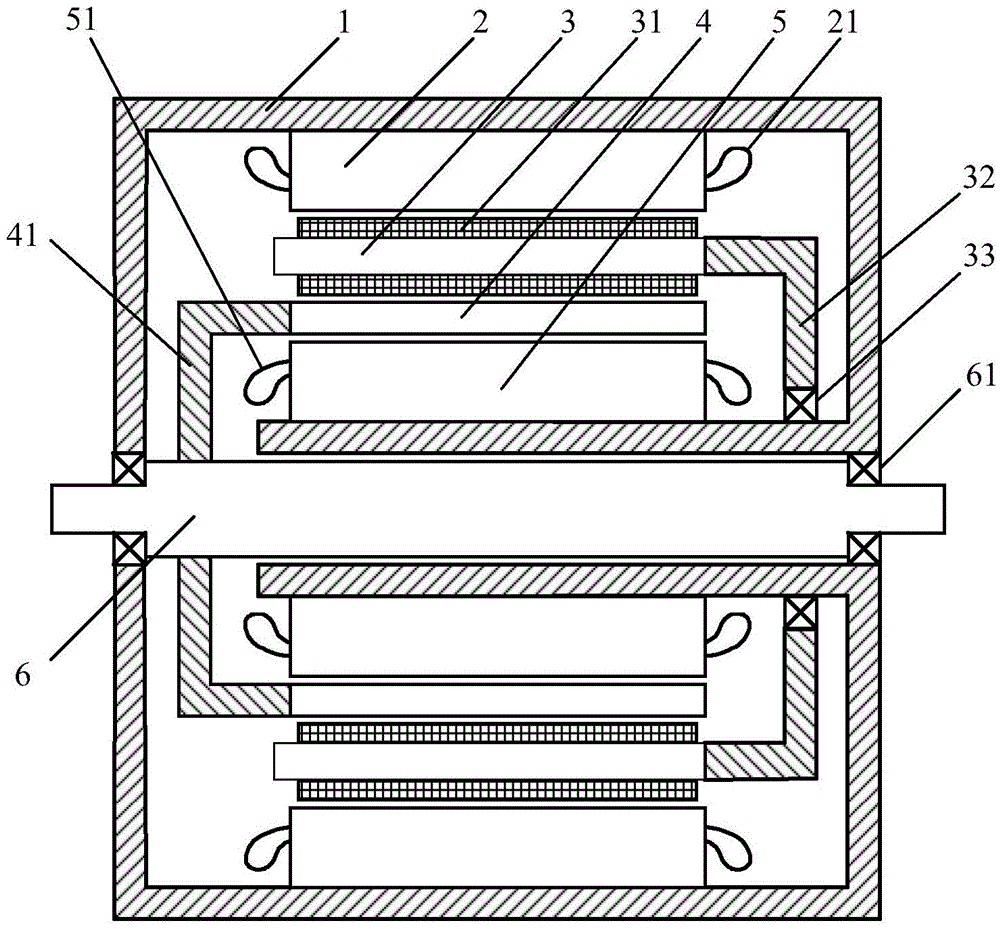

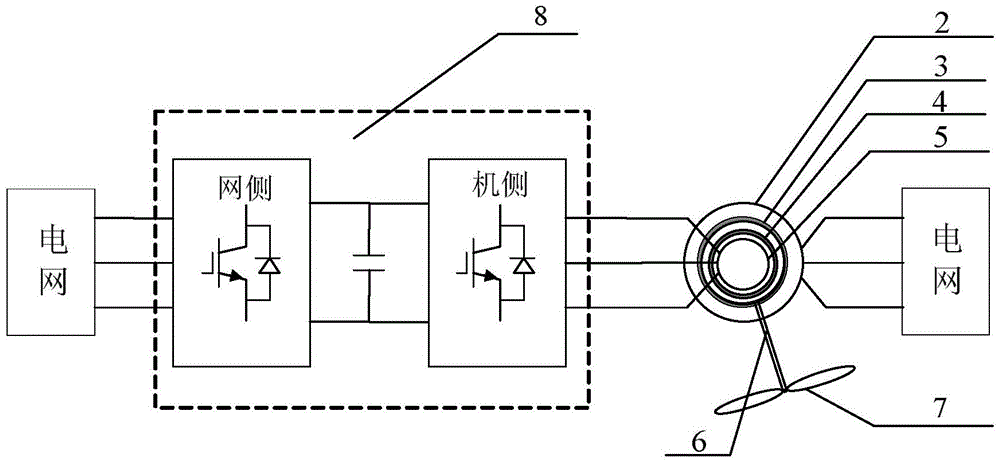

[0021] The double-stator permanent magnet brushless double-fed wind power generator of the present invention includes an outer stator, an outer rotor, an inner rotor, an inner stator and a rotating shaft, and the outer stator and the inner rotor are respectively arranged on the outer circumference and inner circumference of the outer rotor; The inner stator is located on the inner periphery of the inner rotor. The outer rotor is fixed on the outer rotor end cover, and the outer rotor end cover is connected to the machine base through the outer rotor bearing; the inner rotor is fixed on the rotating shaft through the inner rotor end cover, and the rotating shaft is connected to the machine base through a bearing. The outer rotor is coaxial with the inner rotor and can rotate freely; the outer stator and the inner stator are respectively provided with power windings and control windings, and the number of poles of the two sets of windings is different, which are used for power ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com