Magnetic field modulating type concentric magnetic gear transmission device in Halbach magnet structure

A magnetic field modulation and magnetic gear technology, applied in electromechanical transmissions, electromechanical devices, electric components, etc., can solve the problems of weakening the positioning torque of magnetic gear transmissions, non-sinusoidal air gap magnetic density waveform, etc., to improve the utilization of magnets , the effect of reducing harmonic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

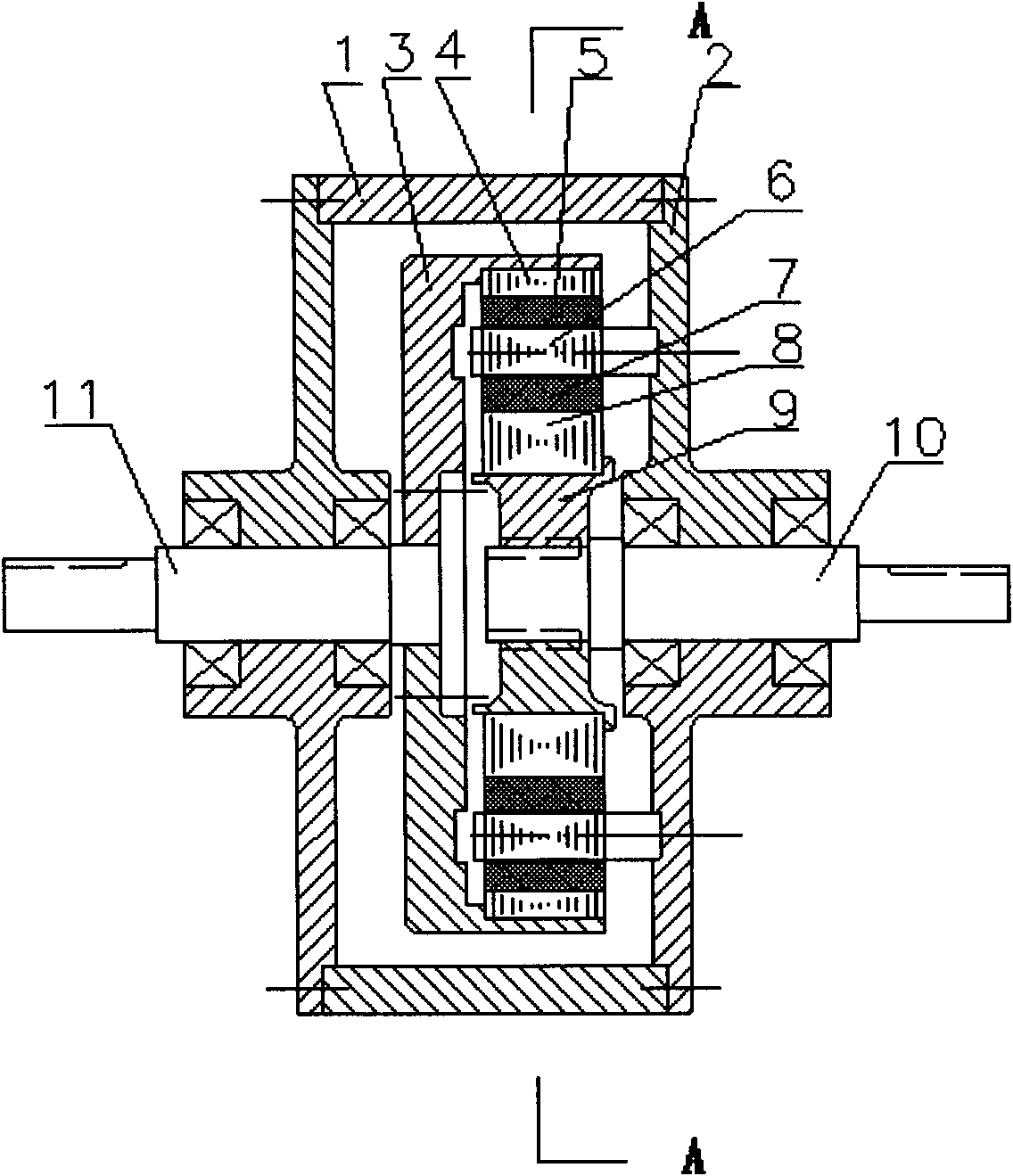

[0025] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

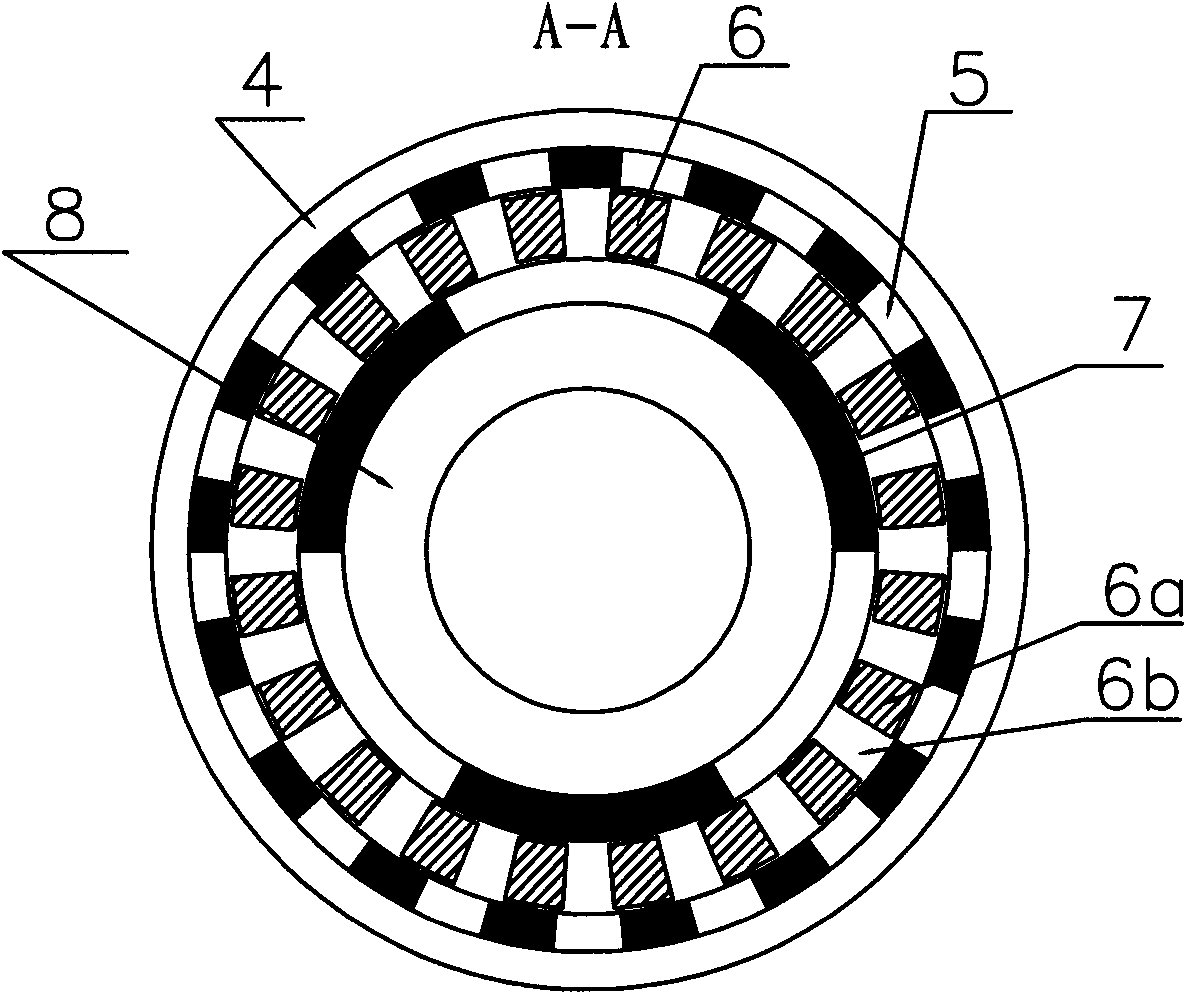

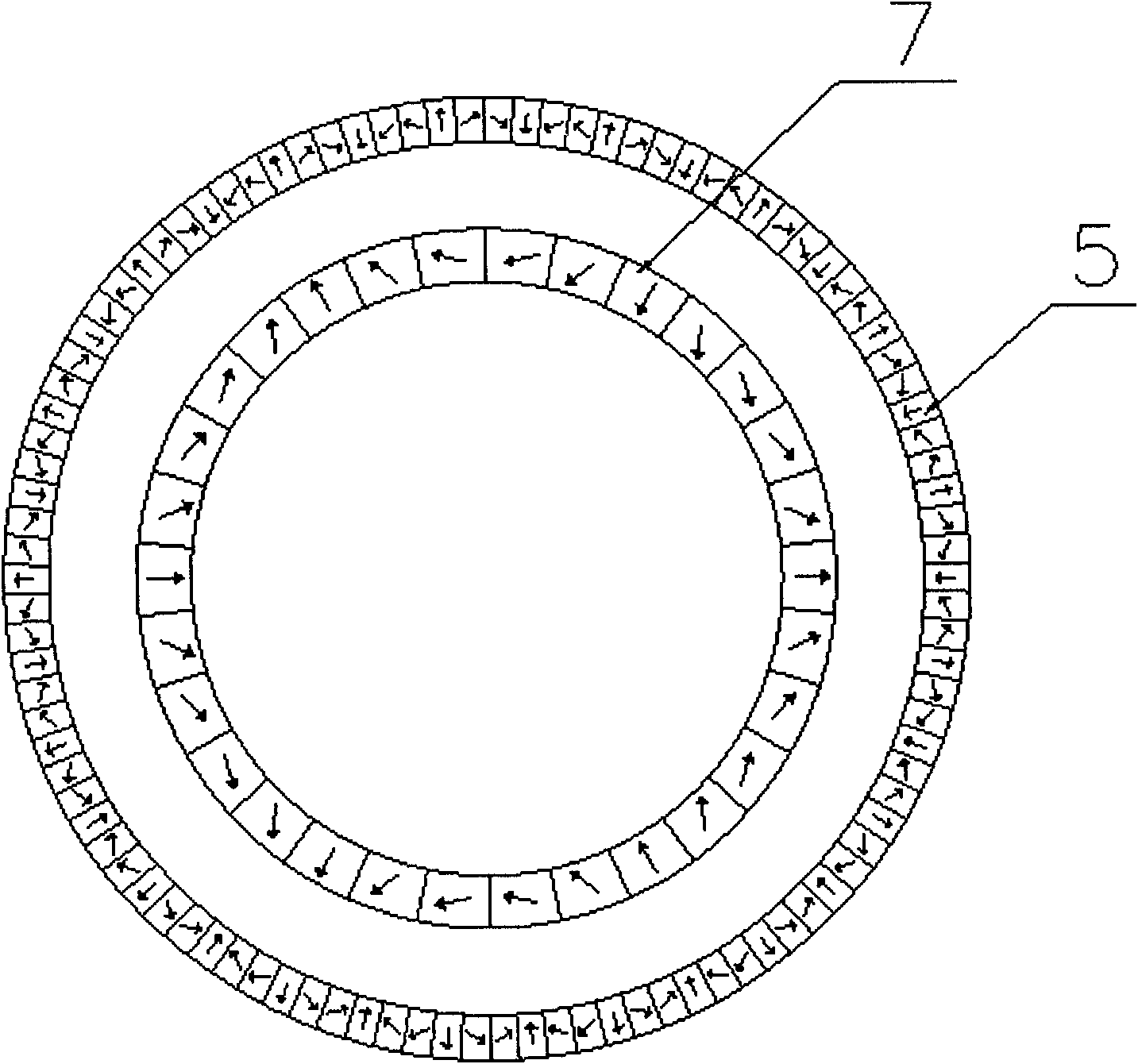

[0026] see figure 1 , figure 2 and image 3 , The Halbach magnet structure magnetic field modulation concentric magnetic gear transmission device includes a housing 1, a cantilevered outer rotor and an inner rotor installed in the inner cavity of the housing 1.

[0027] The outer rotor is a cup-shaped rotor, and an outer rotor core 4 is fixedly installed on the inside of the cup-shaped sleeve 3 at the inner end. 2 The permanent magnet poles constitute the outer rotor magnet ring, and the adjacent permanent magnet poles have different polarities, so there is a total of P 2 For permanent magnet poles, P 2 It is a natural number, and the bottom of the cup at the outer end is connected with an output shaft 11 supported by a bearing.

[0028] The inner rotor is another output shaft 10 supported by bearings, the inner end is fixedly installed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com