Magnetic force assistant slide locating mechanism

A positioning mechanism and magnetic technology, applied in the direction of telephone structure, electrical equipment structural parts, casing/cabinet/drawer parts, etc. Small overall size, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

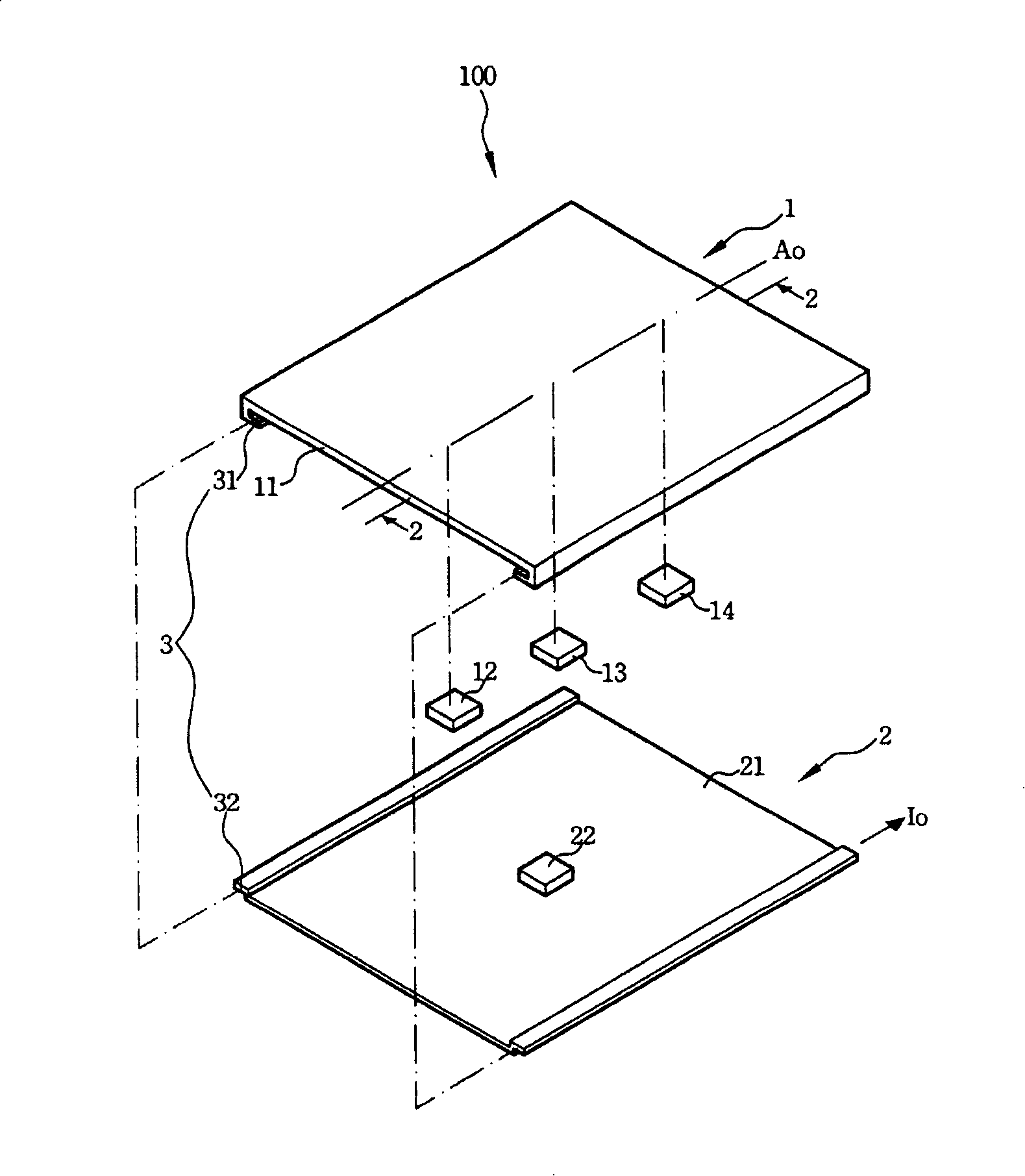

[0078] see image 3 , which shows an exploded perspective view of the first embodiment of the present invention. As shown in the figure, a magnetic-assisted sliding positioning mechanism 200 includes a first platform 4 , a second platform 5 and a sliding guide assembly 6 .

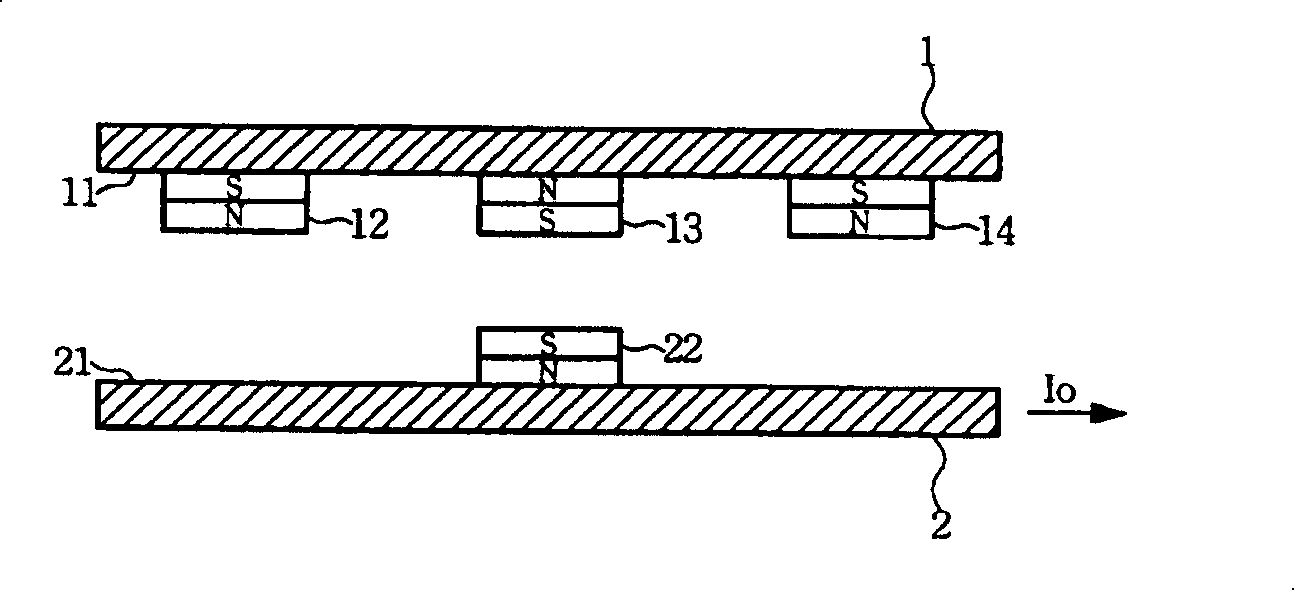

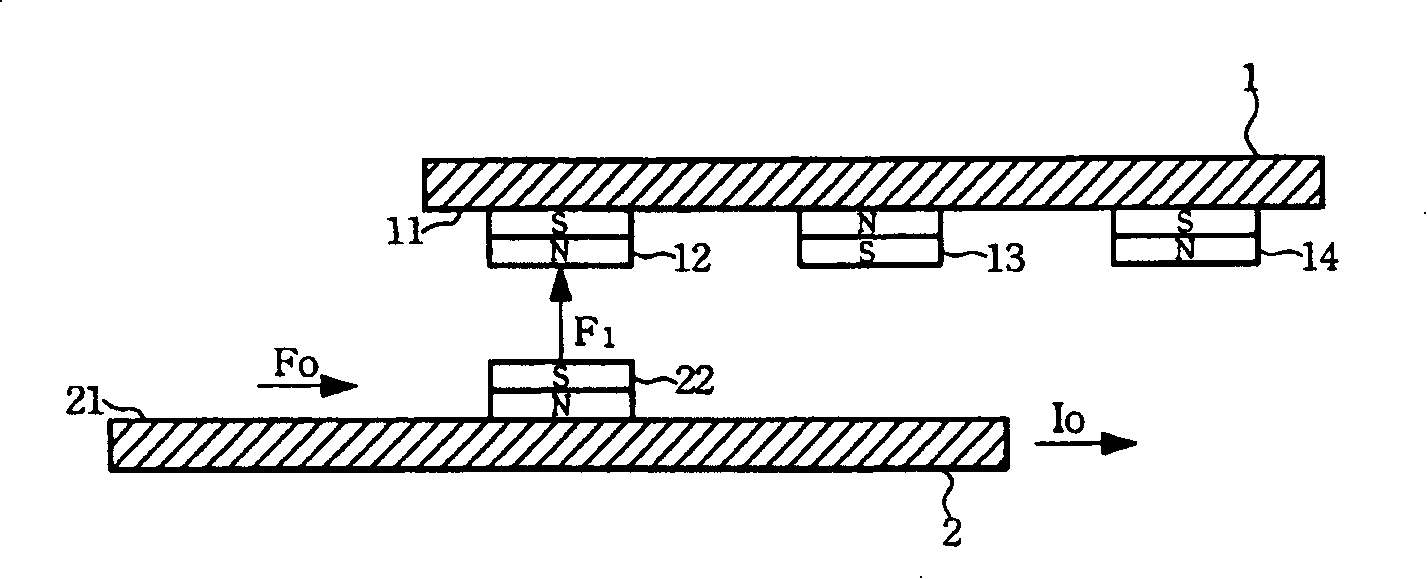

[0079] The first platform 4 has a first working surface 41 on which a double-sided rack 42 and two first magnets 43 and 44 are disposed. Wherein, the first magnets 43 and 44 are disposed at both ends of the double-sided rack 42, and they all have a first magnetic pole (N pole in this embodiment, hereinafter replaced by N pole) and a second magnetic pole (in the In this embodiment, it is the S pole, which will be replaced by S pole below), and the first magnetic poles of the first magnets 43 and 44 are arranged facing each other, and the two sides of the double-sided rack 42 respectively have a rack portion 421 and 422 .

[0080] The second platform 5 has a second working surface 51 , and the second worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com