Magnetic-field modulated-type magnetic screw

A magnetic screw and magnetic field modulation technology, which is applied to permanent magnet clutches/brakes, electric brakes/clutches, electrical components, etc., can solve the problems of large amount of permanent magnets, single magnetic field modulation of magnetic screw screws, and short movement strokes. Achieve the effects of improved linear travel, low maintenance costs, and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

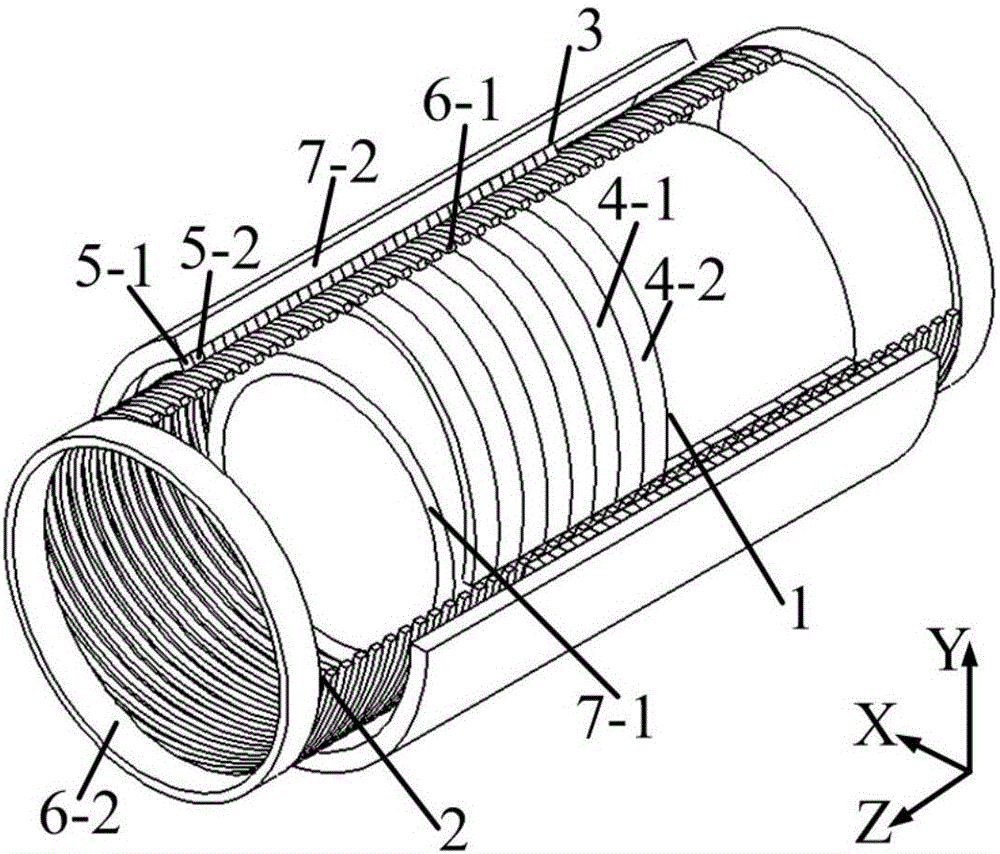

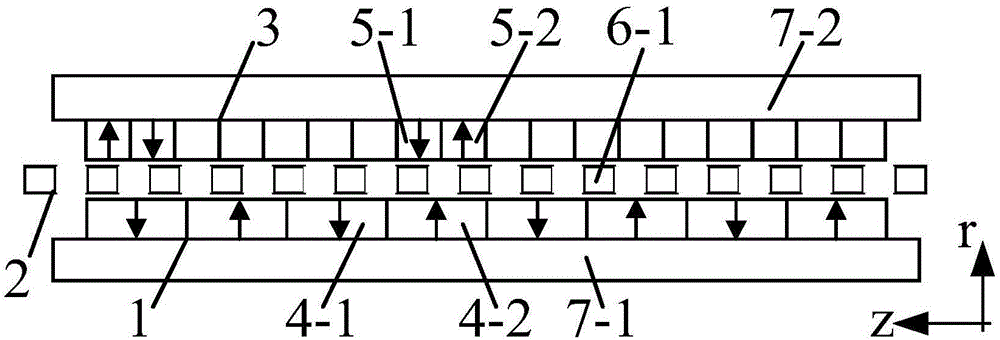

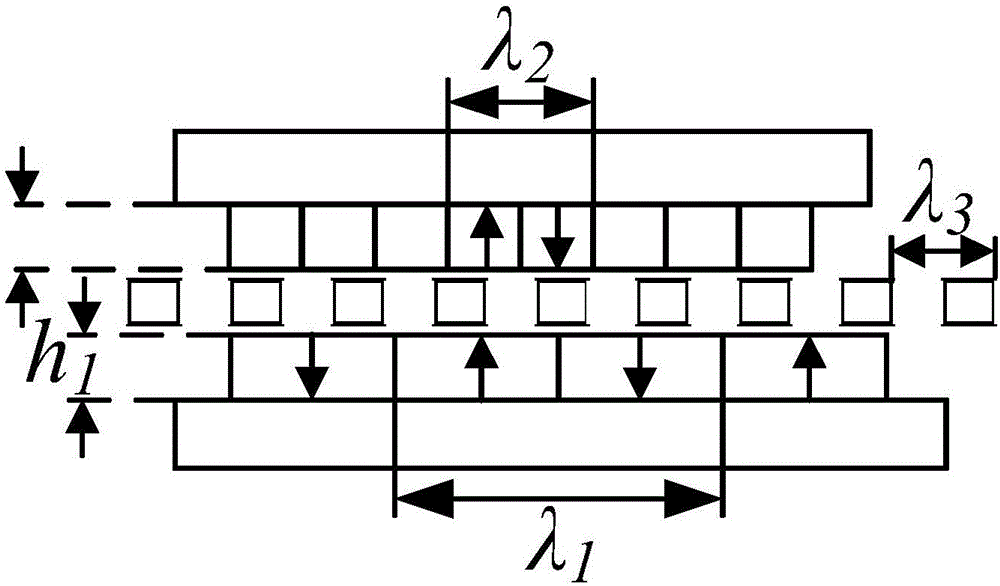

[0028] like Figure 1-2 A magnetic field modulation type magnetic lead screw is shown, including rotor magnetic screw 1, mover iron ring 2 and stator magnetic nut 3, the three are coaxially installed in sequence from inside to outside, mover iron ring 2 and rotor There is an air gap between the magnetic screw 1, between the mover iron ring 2 and the stator magnetic nut 3, the thickness of the air gap is selected according to the size and requirements of the screw, the rotor magnetic screw 1 performs a helical movement along the Z axis, and the stator magnetic The nut 3 is fixed, and the mover iron ring 2 moves linearly along the Z axis.

[0029] The rotor magnetic screw 1 includes a spiral permanent magnet a4-1, a spiral permanent magnet b4-2 and an electrical iron ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com