Expanded-polystyrene plate insulation packaging box

A foam plastic board and packaging box technology, applied in the field of foam plastic board thermal insulation packaging box, can solve the problems of reducing the capacity of the packaging box, poor fresh-keeping effect, etc., and achieve the effect that the cost will not increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

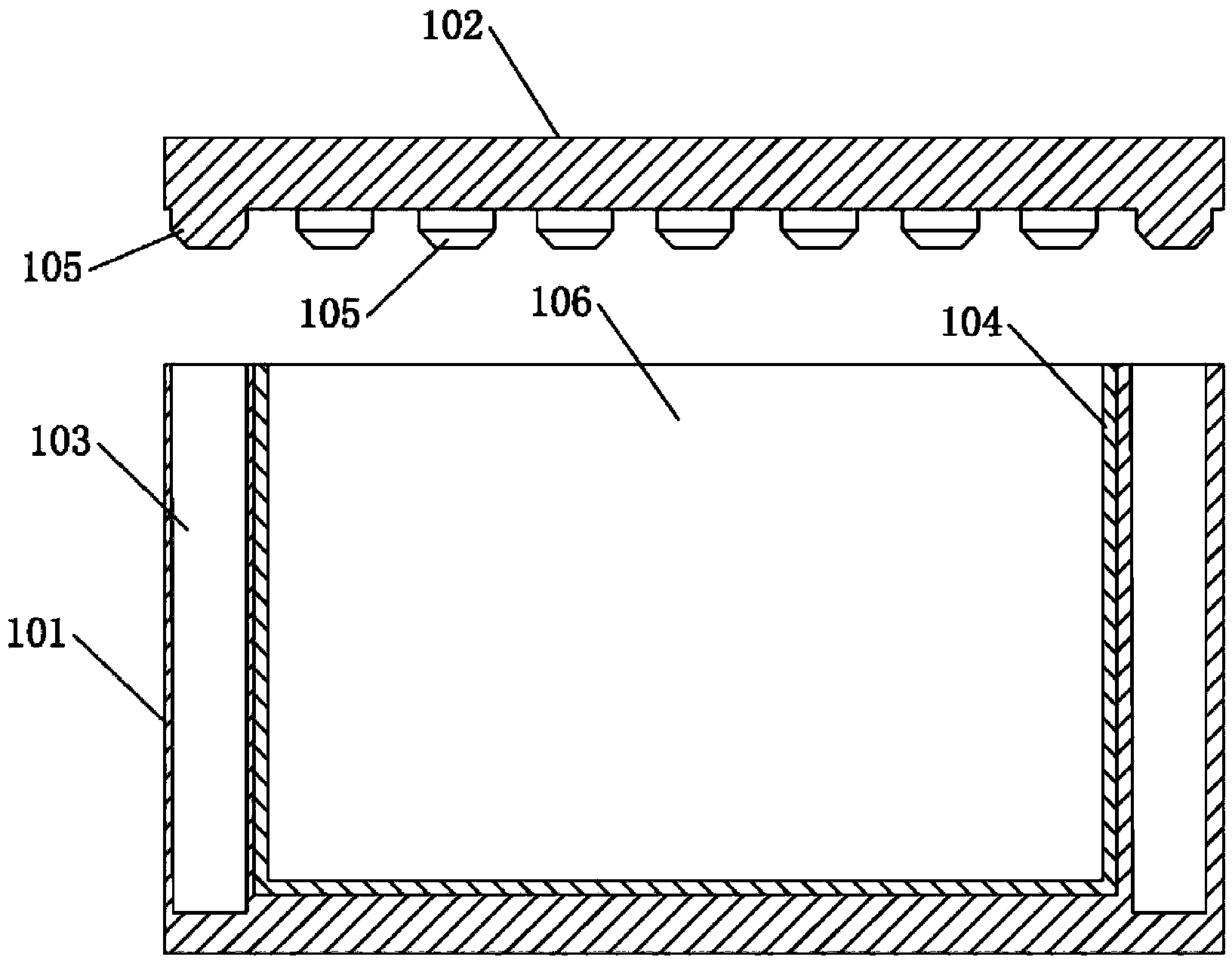

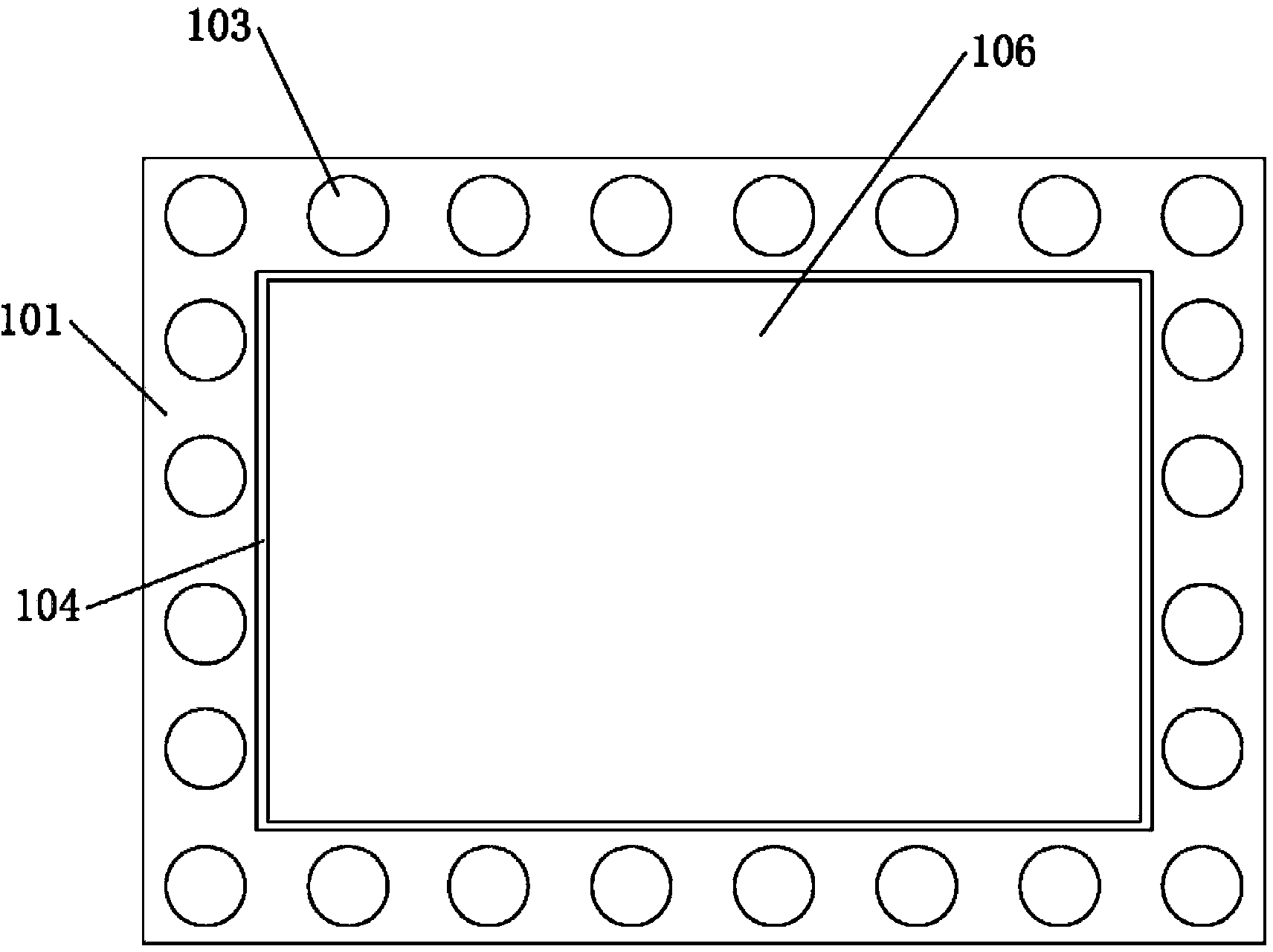

[0017] see figure 1 and figure 2 , the preferred embodiment of the present invention provides a foam plastic board heat preservation packaging box, comprising a foam plastic board box body 101 and a box cover 102 covering the foam plastic board box body 101, and the side plate of the foam plastic board box body 101 is opened There are a plurality of blind holes 103 for placing fresh-keeping media, and the blind holes 103 are arranged at equal intervals on the side plate of the foam plastic board box body 101, and the depth of the blind holes 103 is greater than or equal to the inner cavity 106 of the foam plastic board box body 101 The depth of the box cover 102 is provided with a hole plug 105 corresponding to the blind hole 103, and the end of the hole plug 105 is conical.

[0018] When transporting articles, the article is directly placed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com