Spring steel and surface decarbonization control process thereof

A technology of spring steel and process, which is applied in the field of spring steel and its surface decarburization process, can solve the problems that the surface decarburization layer of spring steel cannot reach the uniformity of steel structure, complex production process, poor performance stability, etc., and achieve superior performance , Simple production process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

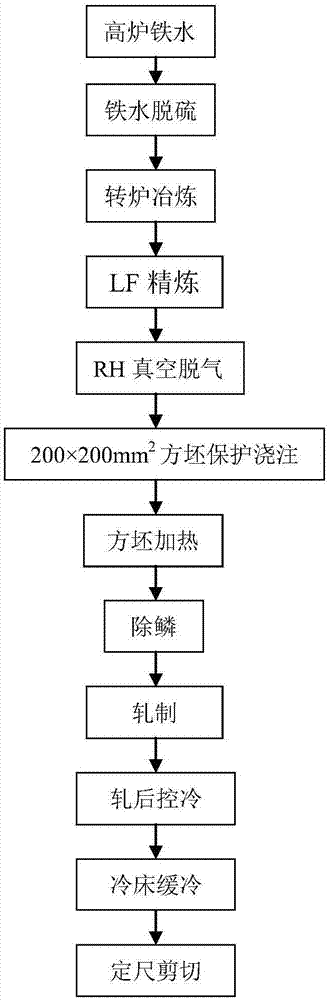

[0037] The preparation method (surface decarburization control process) of spring rigid described in embodiment 1~10 comprises the following steps:

[0038] 1) Desulfurization of molten iron: the magnesium powder desulfurization process is adopted to control the sulfur content of molten iron leaving the station [S]≤0.005wt%;

[0039] 2) Converter oxygen blowing smelting: 120 tons of converter oxygen blowing smelting is adopted to ensure that the carbon temperature is coordinated when tapping, and silicon-manganese alloy, ferrosilicon, high-carbon ferrochrome, ferro-niobium and carbon powder are added when tapping 1 / 3 of the steel, and molten steel Alloy and recarburizer (carbon powder) must be completely added when the output reaches 2 / 3;

[0040] 3) Argon blowing: the obtained ladle molten steel is blown with argon at the argon station, and the blowing time is not less than 3 minutes;

[0041] 4) Refining outside the furnace: refining in the LF furnace, adding active lime an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com