Tearing-proof high temperature resisting conveyer belt

A technology of high temperature resistance and conveyor belt, which is applied in the field of transportation engineering, can solve the problems of inconvenient operation, easy tearing, and reduced service life of the conveyor belt, so as to improve the performance of tear resistance and high temperature resistance, uniform and fine cracks, and glue The effect of reasonable ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

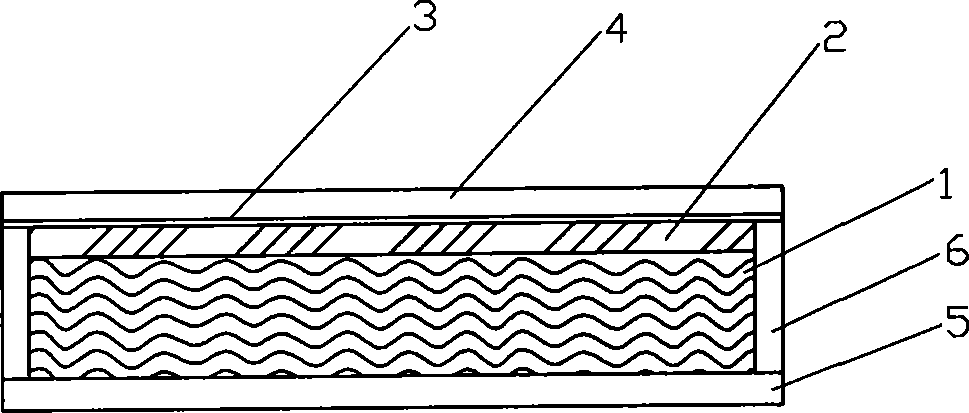

[0015] A schematic cross-sectional view of the present invention as shown in the accompanying drawings. The core of the main body of the present invention is the skeleton layer 1, and the material it adopts is polyester cloth with low heat shrinkage. The shrinkage is small, and the belt body can be kept without deformation. A transverse reinforcement layer 2 is arranged on the top of the skeleton layer 1, and this layer adopts a polyester curtain net, which has the function of enhancing the tear resistance of the belt body and enhancing the endurance resistance of the belt body skeleton layer 1. A buffer rubber layer 3 is arranged between the working surface cover rubber layer 4 and the reinforcing layer 2. The buffer rubber layer 3 is a blend of EPDM rubber and natural rubber. The layer 4 and the transverse reinforcement layer 2 play the role of bridging. On this basis, EPDM special adhesive (R-33) is added for bonding and supplementation, thereby strengthening the working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com