Corrugated steel web prestressed concrete continuous box girder and construction method thereof

A corrugated steel web, precast concrete technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems that conventional construction equipment is difficult to meet installation requirements, the installation weight of each box girder increases, and the promotion and application difficulties are difficult to achieve. The effect of expanding the scope of application of span, small deformation and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

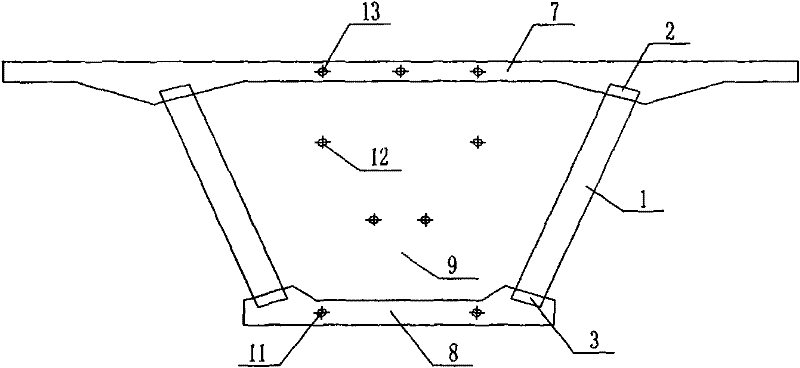

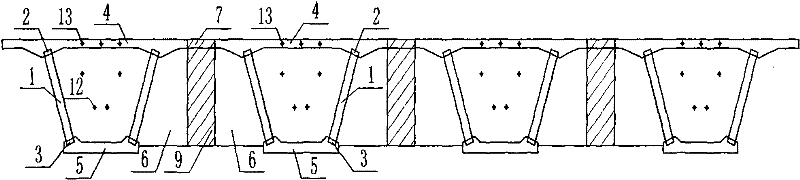

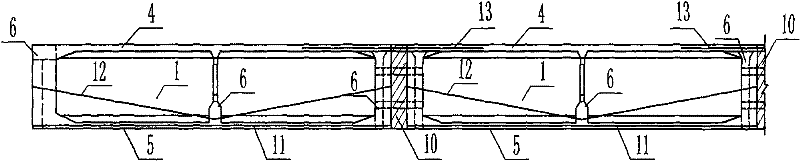

[0021] Such as Figure 3-6 Shown: a corrugated steel web prestressed concrete continuous box girder. Concrete beams or diaphragms 6 and prestressed tendons 11 in the bottom plate. The upper connector 2 is located on the upper end of the corrugated steel web 1 . It is welded and fixed with the corrugated steel web 1 and embedded in the precast concrete roof 4 . The upper connector 2 consists of an upper wing plate, double-holed steel ribs, and transverse perforated steel bars. The upper wing plate is made of steel. Pass through the openings of the double-opened steel ribs. The lower connecting piece 3 is located at the lower end of the corrugated steel web 1 and is embedded in the precast concrete bottom plate 5 . The lower connector 3 can be a hole at the bottom of the corrugated steel we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com