Aluminum, plastic and wood composite window sections

A technology of aluminum profiles and composite windows, which is applied in the direction of wing and leaf frames, etc., can solve the problems of poor thermal insulation performance, high production energy consumption, poor weather resistance, etc., and achieve good thermal insulation performance, low production energy consumption and decorative effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

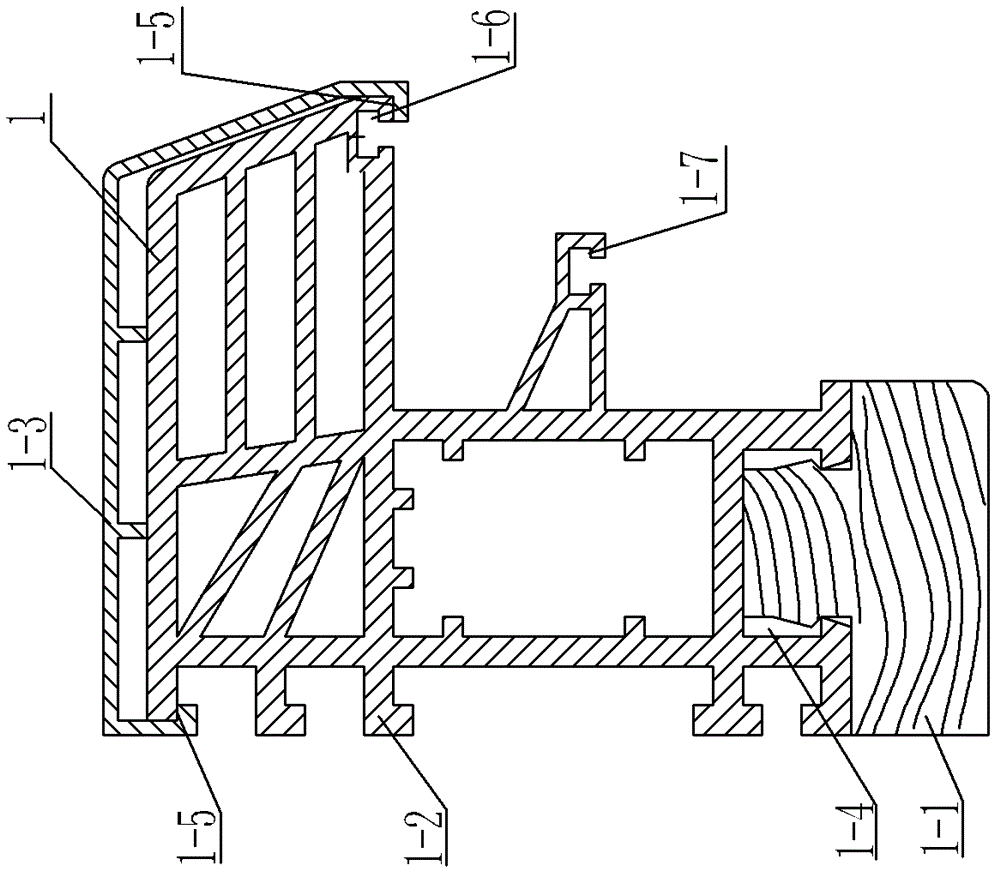

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment. An aluminum-plastic-wood composite window frame profile in this embodiment is composed of a frame wood profile 1-1, a frame plastic profile 1-2, and a frame aluminum profile 1-3. The frame plastic profile 1-2 is set on the frame The wood profile 1-1 and the frame aluminum profile 1-3 are detachably connected.

[0013] The frame plastic profile 1-2 of this embodiment is a hollow structural member with special-shaped cross-section, which has a high cross-section rigidity, and is respectively connected with corresponding wood profiles and aluminum profiles to form a firm and stable frame profile.

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the lower end of the frame plastic profile 1-2 described in this embodiment is provided with a groove 1-4, and the section of the frame wood profile 1-1 is convex, and the frame wood profile 1-1 is convex. The protruding end of 1-1 is plugged into the groove 1-4 of the frame molding profile 1-2. With such arrangement, the assembly is convenient and meets the design requirements. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the two sides of the frame aluminum profile 1-3 described in this embodiment are each provided with an insertion groove 1-5, and the frame plastic profile 1-2 is inserted into the insertion groove of the frame aluminum profile 1-3 1-5, the upper right side of the frame plastic profile 1-2 is provided with an upper sealant strip groove 1-6, and the lower right side of the frame plastic profile 1-2 is provided with a lower sealant strip groove 1 -7. With such arrangement, the assembly is convenient and fast, and meets the design requirements. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com