Continuous box girder made of corrugated steel web pre-tensioned prestressed concrete and construction method

A corrugated steel web and precast concrete technology, which is applied in bridges, bridge materials, bridge construction, etc., can solve problems affecting construction quality and structural durability, affecting material utilization, and insufficient bearing capacity of prestressed concrete continuous girder bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

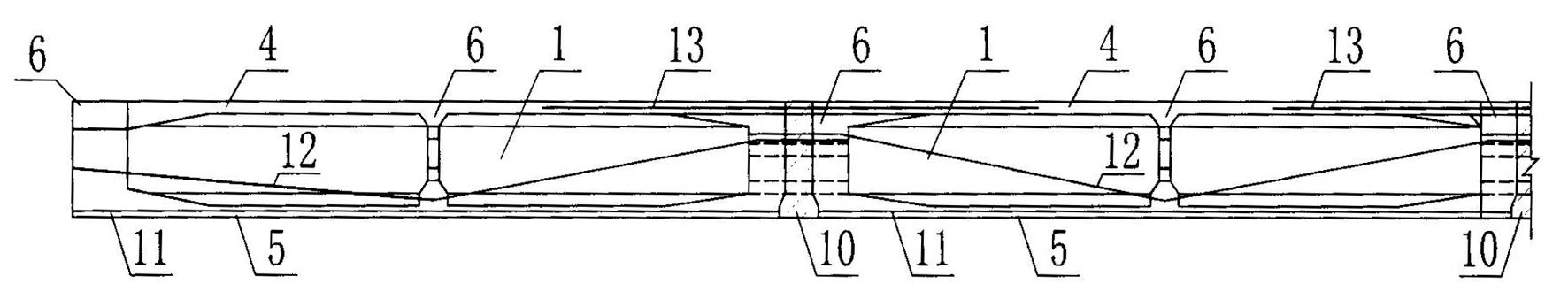

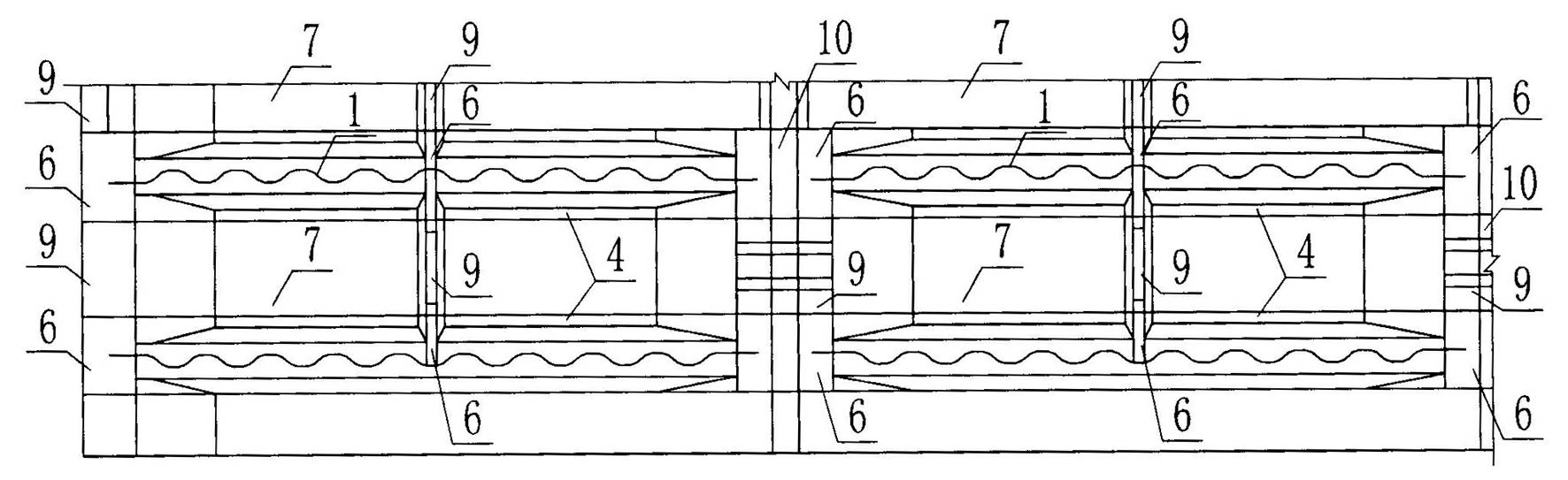

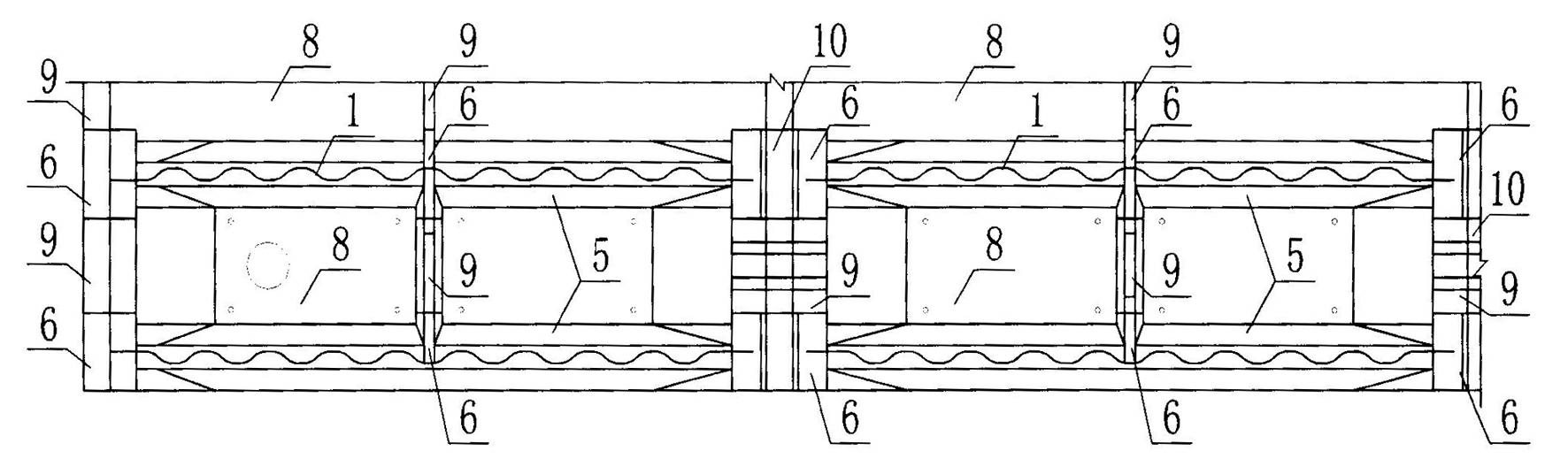

[0025] Such as Figure 1~4 Shown: A corrugated steel web pretensioned prestressed concrete continuous box girder includes multiple prefabricated I-beam units arranged in the transverse and longitudinal directions of the bridge. Among them, there are at least two horizontal spans and at least two vertical spans. In this way, at least four I-beams are required to form a two-span single-box single-room continuous box girder. Similarly, multi-span continuous box girders can be formed. When the bridge is wider, more than four I-beams are needed to form more than two box girders in each horizontal span.

[0026] Such as Figure 5As shown: each I-beam unit is mainly composed of corrugated steel web 1, upper connector 2, lower connector 3, precast concrete roof 4, precast concrete bottom slab 5, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com