Assembled bridge deck transverse joint using UHPC grouting material

A technology of transverse joints and bridge decks, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of reducing the width of wet joints, reducing the length of anchoring of steel bars, and complicated welding or binding of steel bars, so as to achieve good bonding. The effect of performance, simple and efficient construction, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

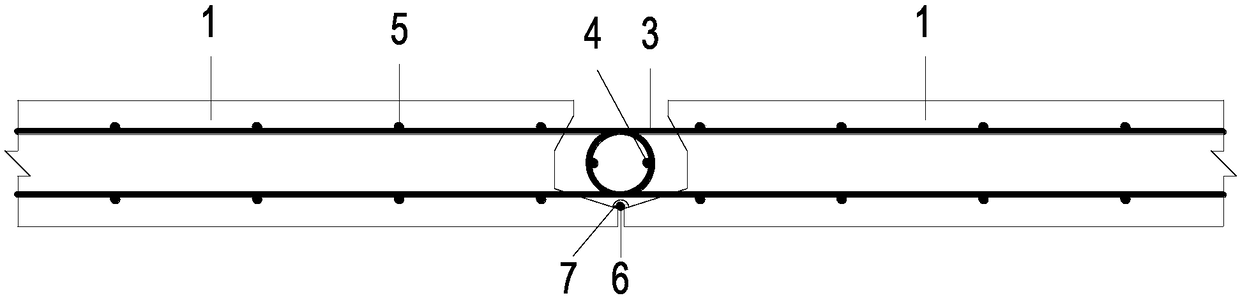

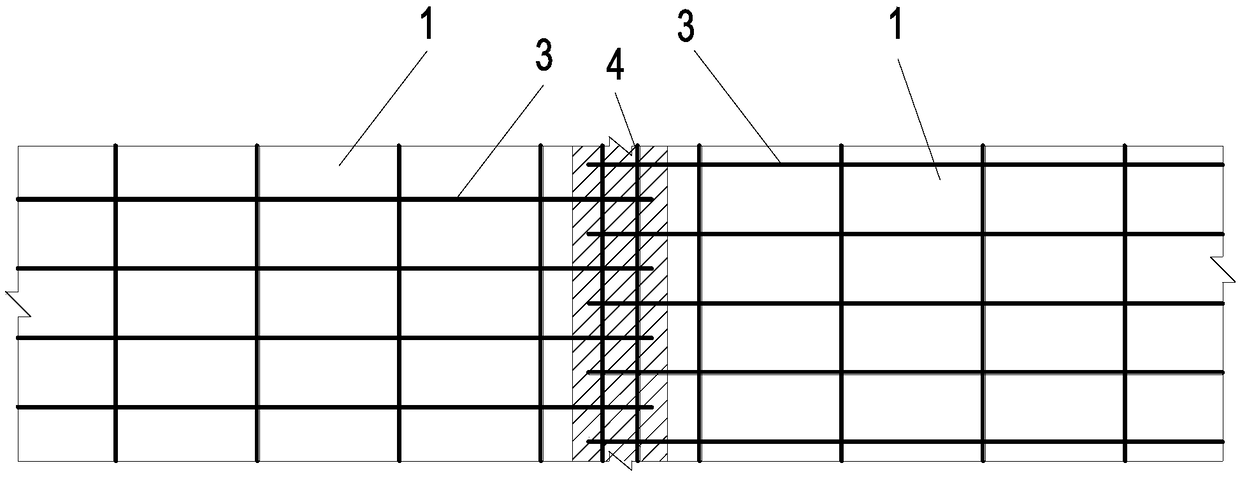

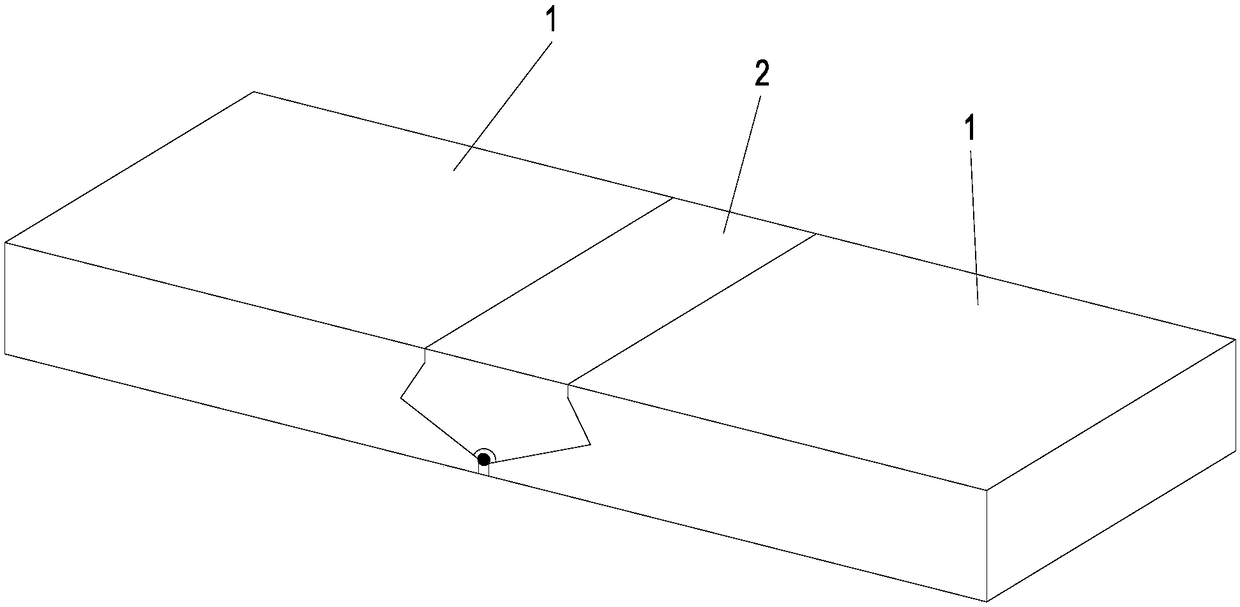

[0022] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-3 As shown, a fabricated bridge deck transverse joint using UHPC grouting material, including two precast concrete bridge decks 1 with grooves and UHPC grouting material 2 poured between the two precast concrete bridge decks, the precast concrete The bridge deck 1 is provided with a steel skeleton spliced by several transverse steel bars and longitudinal steel bars, and pouring concrete on the basis of the steel skeleton in the factory to obtain a prefabricated concrete bridge deck;

[0023] The longitudinal steel bar is a double-layer U-shaped steel bar structure arranged in a U-shaped structure at the rebate end. The U-shaped steel bars at the rebate position between the two precast concrete bridge decks are staggered and interspersed with each other. The rebate of the two precast concrete bridge decks The ends ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top width | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com