Assembling type plate-beam connecting joint and construction method thereof

A node-connecting and prefabricated technology, applied in floors, building components, buildings, etc., can solve the problems of high labor intensity of workers, low level of industrialization of hollow floors, and poor integrity, so as to overcome poor overall performance and insignificant increase in cost. , The effect of flat and beautiful exterior facade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

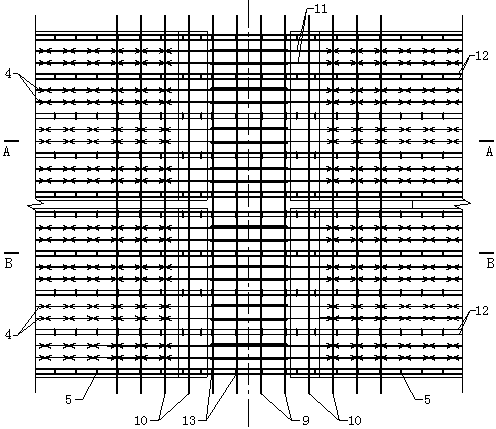

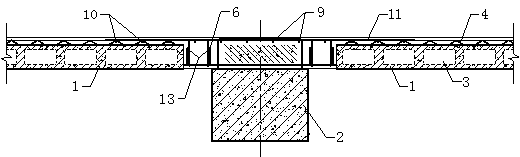

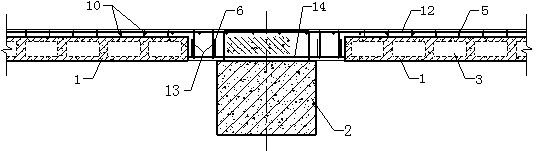

[0029] In order to further describe the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0030] Such as Figure 1-7 As shown, a prefabricated slab-beam connection node includes: densely ribbed box-type composite floor 1 and laminated beam 2, characterized in that: the densely ribbed box-type composite floor 1 and laminated beam 2 pass through Floor rib beam stirrups 5, floor protruding bent steel bars 6, composite beam longitudinal reserved ribs 7, truss bars transverse connecting bars 11, rib beam transverse linking bars 12, slab girder contact area stirrups 13, U-shaped lap joints The steel bars 14 are connected in sequence, and are connected in sequence through the horizontally reserved ribs 7 of the composite beam, the longitudinal ribs 9 in the upper area of the beam, and the longitudinal ribs 10 in the plate area.

[0031] The densely ribbed box-type composite floor 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com