Dual-direction pre-tensioning system prestressed concrete track slab

A track slab and prestressing technology, applied in tracks, roads, ballast layers, etc., can solve problems such as cracks or fractures of track slabs, increased cost of track slabs, low production efficiency, etc., and achieves improved service life, simple construction, and structural reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

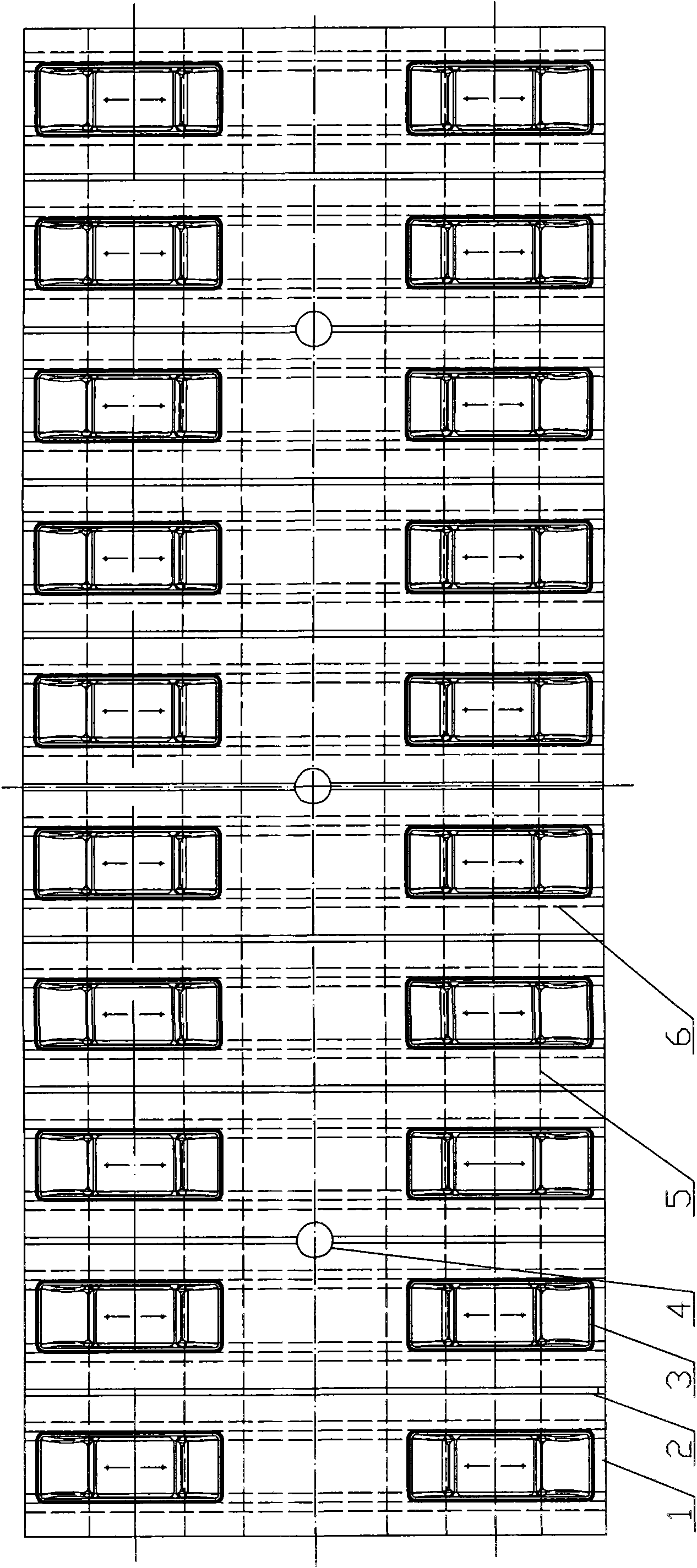

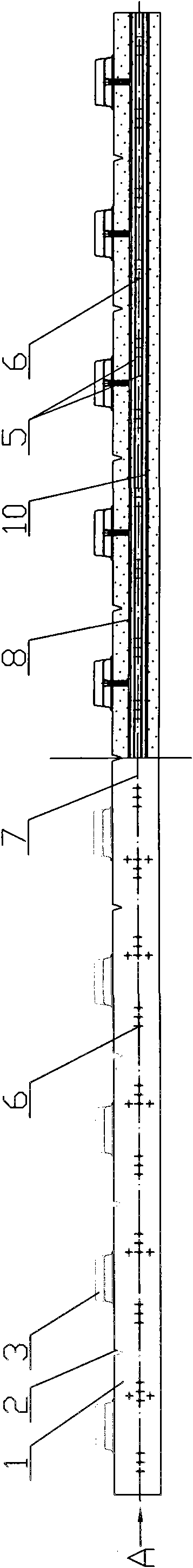

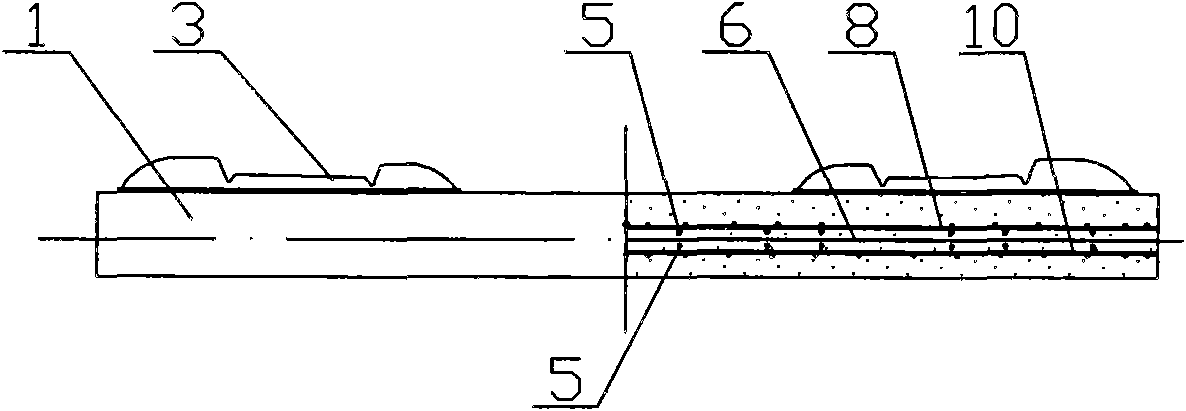

[0013] Depend on Figure 1-Figure 3 A two-way pre-tensioning method prestressed concrete track slab is shown, including a rectangular track slab body 1, and the upper surface of the track slab slab body 1 is provided with a rail part 3 and a groove 2 at intervals, and the groove 2 is arranged in the adjacent Between the two supporting rail parts 3, a structure 4 is reserved on the track plate body 1, and a steel bar layer is horizontally arranged in the track plate body 1, and the steel bar layer includes a longitudinal steel bar layer and a transverse The reinforcing bars 5 and 6 in the layers are arranged at intervals, the reinforcing bars 5 in the longitudinal reinforcing bar layer extend along the length direction of the track plate body 1, and the reinforcing bars 6 in the horizontal reinforcing bar layer extend along the width direction, including the upper and lower steel meshes arranged evenly and horizontally. 8, 10, the upper steel wire mesh 8, the longitudinal reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com