Prefabricated reinforced concrete component and assembly type building comprising same

A reinforced concrete and component technology, which is applied to buildings, building components, building structures, etc., can solve the problems of inability to guarantee connection strength, inconvenient reinforcement construction, and unfavorable labor efficiency, so as to improve labor efficiency, simplify construction, and connect reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

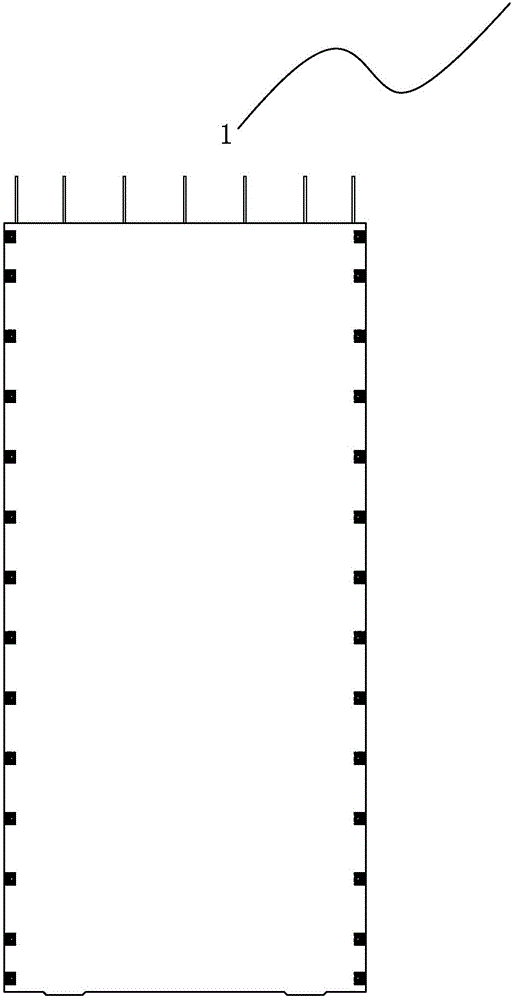

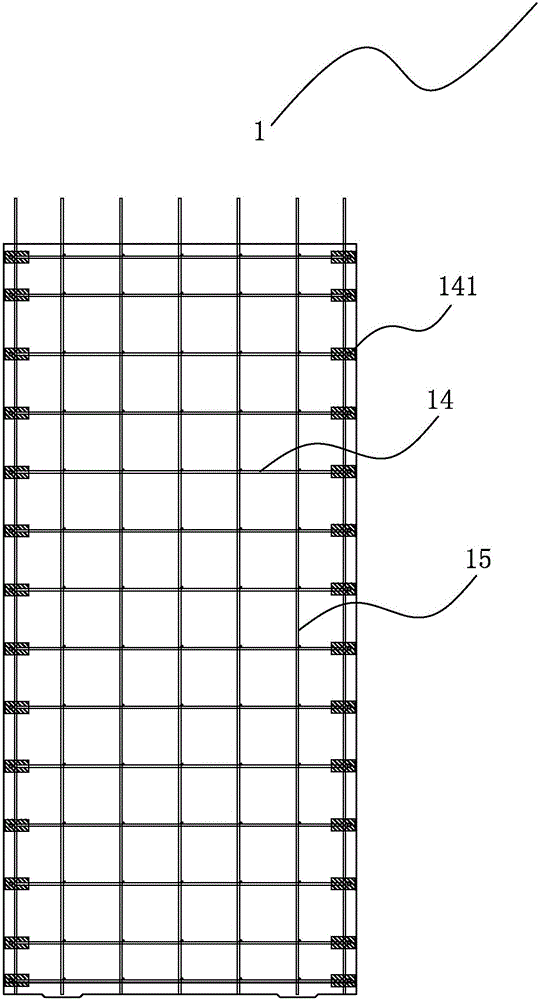

[0037] Such as figure 1 As shown, the prefabricated reinforced concrete member 1 of the present invention is prefabricated with concrete. Such as Figure 5As shown, the component 1 is provided with a through hole 11 running through its length direction. Both side plates of the component 1 are provided with grooves 12 parallel to the through holes 11 . This embodiment only takes the through hole 11 as a round hole and the cross section of the groove 12 as an example for illustration. The shape of the above-mentioned through hole 11 can also be set as an oval hole, a square hole or a semicircle at both ends according to actual operation requirements. There is a rectangular hole in the middle, and the cross section of the groove 12 can also be in the shape of a semi-ellipse, a rectangle, or a combination of a semi-circle and a rectangle.

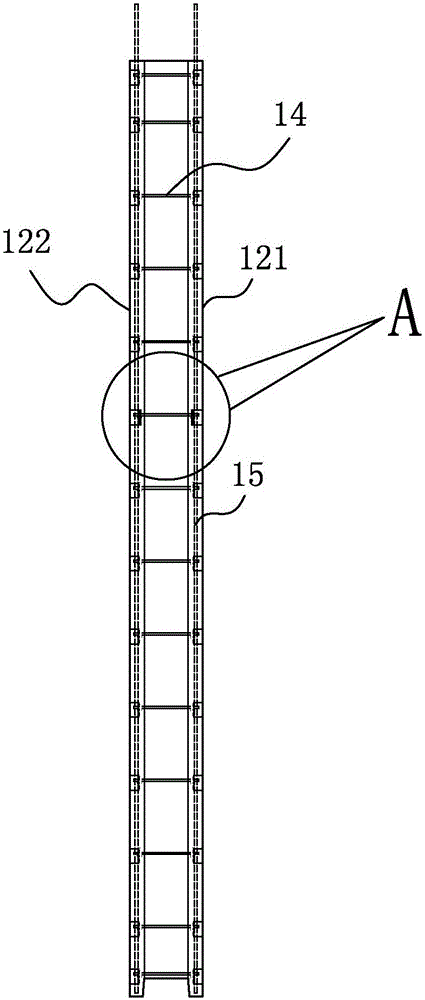

[0038] Such as Figure 2 to Figure 6 As shown, the component 1 includes an outer wall panel 121 adjacent to the above-mentioned side panel...

Embodiment 2

[0047] Such as Figure 12 As shown, the difference between this embodiment and the first embodiment is that the component 1' is only provided with a groove 12' on one side plate.

Embodiment 3

[0049] Such as Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that the component 1 "is only provided with an embedded part 141 " at the left end of the transverse steel bar 14 ", and when in use, the operation on the right side with the embedded part 141 "is the same as The same as the first embodiment, the left end of the transverse steel bar 14 ″ without the embedded part 141 ″ is inserted into the floor concrete, which greatly increases the strength of the transverse connection between the member 1 ″ and the floor slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com