Pre-cast concrete column and method of fabrication

a pre-cast concrete and column technology, applied in the field of concrete columns, can solve the problems of weakening the concrete column formed therefrom, voids and pockets between the five pieces of rebar, and crevices that are difficult to fill with concrete, and achieve the effect of easy flow and easy flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

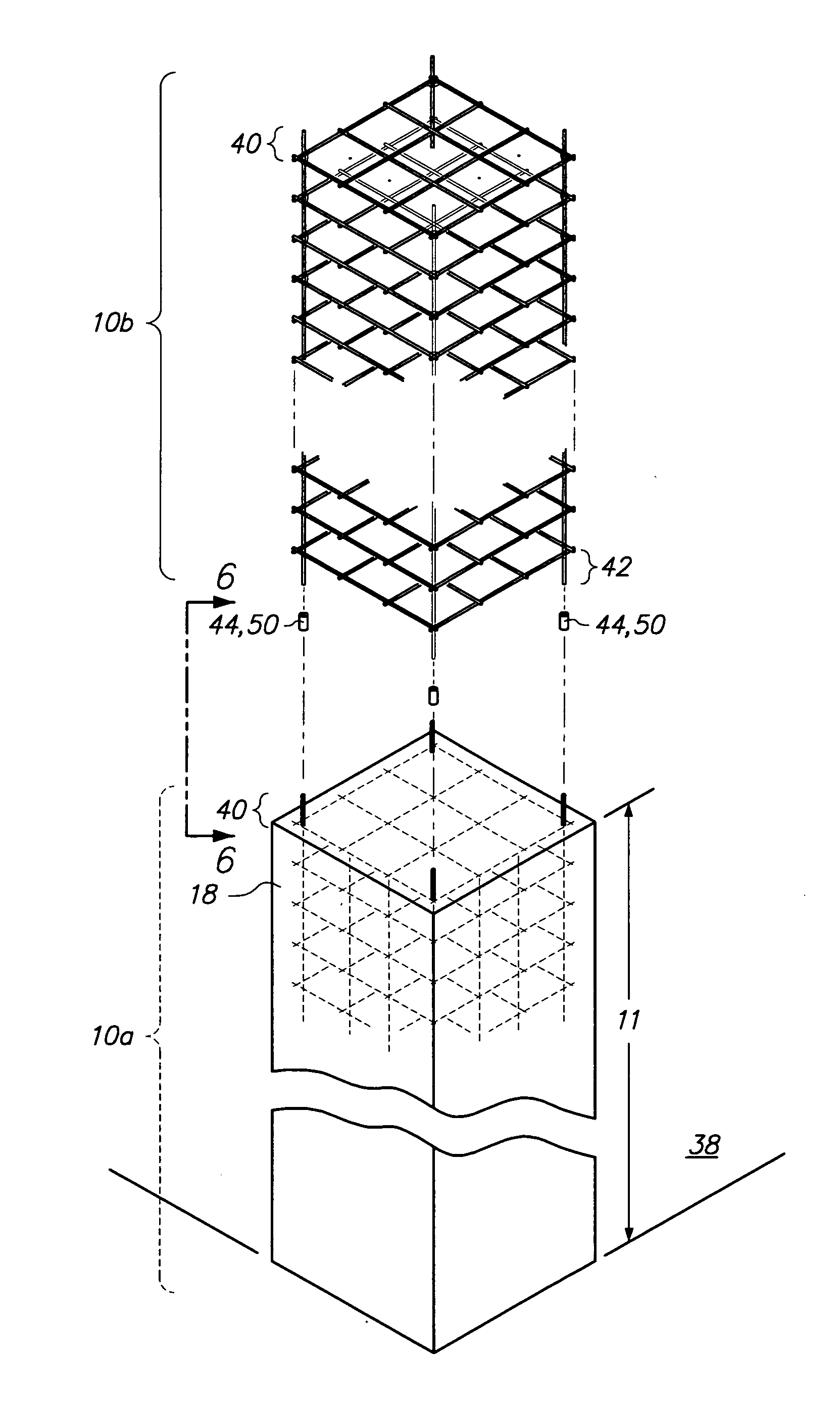

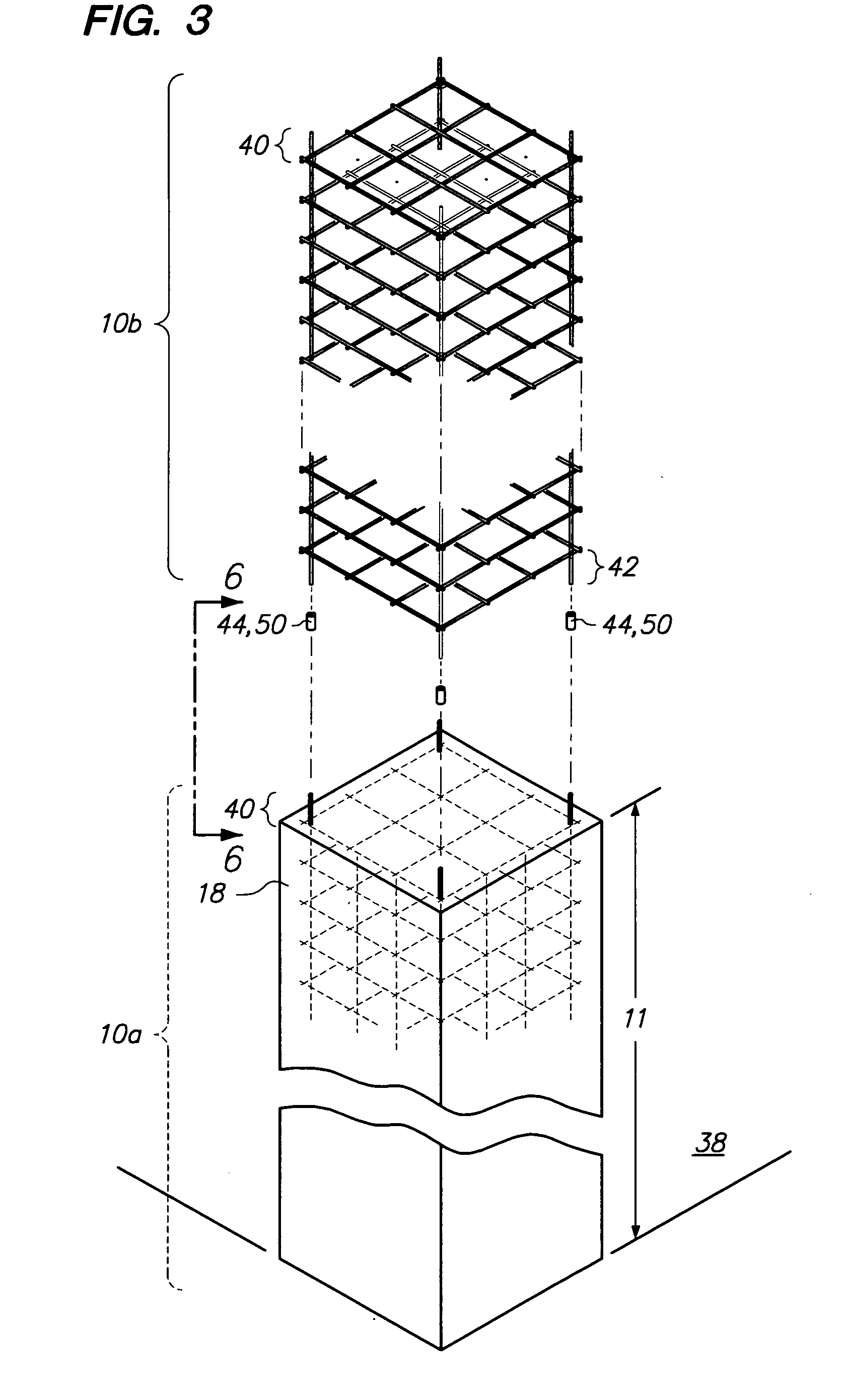

[0023]Referring now to FIG. 3, column cages 10a, b are shown. Each of the column cages 10a, b may be fabricated in a manner so as to be longer than a standard prior art column cage. In particular, prior art column cages are typically fabricated in thirty feet length. In contrast, the column cages 10a, b shown in the drawings may be fabricated in lengths 11 longer than thirty feet. Since rebar is typically provided in sixty feet length, the column cages 10a, b may each be fabricated up to sixty feet long. However, in the event that rebar greater than sixty feet can be provided, the column cages 10a, b may each be fabricated greater than sixty feet and up to the length of the rebar. Since the column cages 10a, b may be fabricated in a length 11 longer than standard prior art column cages, fewer column cages 10a, b are interconnected to each other to reach a required height. Accordingly, less rebar couplers 44, 50 are needed to couple column cages 10a, b together and also greater heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com