Plug welding repair technology for mammoth converter shell perforation

A welding repair, large converter technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of easy cracking, large welding stress, complex process, etc., and achieve high production efficiency, reliable welding quality, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Taking 300 tons of converter shell burning perforation welding repair as an example below, to illustrate the large-scale converter shell perforation plug welding repair process of the present invention, the specific method is as follows:

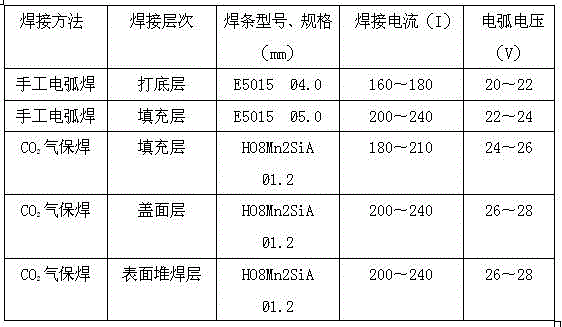

[0012] 1) Welding method: manual arc welding + CO 2 Gas shielded welding plug welding, the thinning position is to use CO 2 Gas shielded welding surfacing.

[0013] 2) Welding sequence: Welding on the inner side of the furnace body, first by manual arc welding plug welding 1 / 3 depth, and then by CO 2 Gas shielded plug welding.

[0014] 3) Welding material: manual arc welding uses J507 ultra-low hydrogen electrode, specifications φ3.2, φ4.0, and the power supply adopts DC reverse connection. Dry the J507 ultra-low hydrogen electrode welding at a temperature of 350-400°C and keep it warm for 2 hours. The baked electrodes are placed in a 100°C heat preservation cylinder and taken out as needed. Wet welding rods are strictly prohibite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com