Welding repair method for large nodular iron castings

A welding repair and welding method technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve problems such as hot cracks, cold cracks in ductile iron welded joints, etc., achieve high operability, reduce dilution rate, method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A welding repair method for large ductile iron castings, the specific technical scheme is as follows:

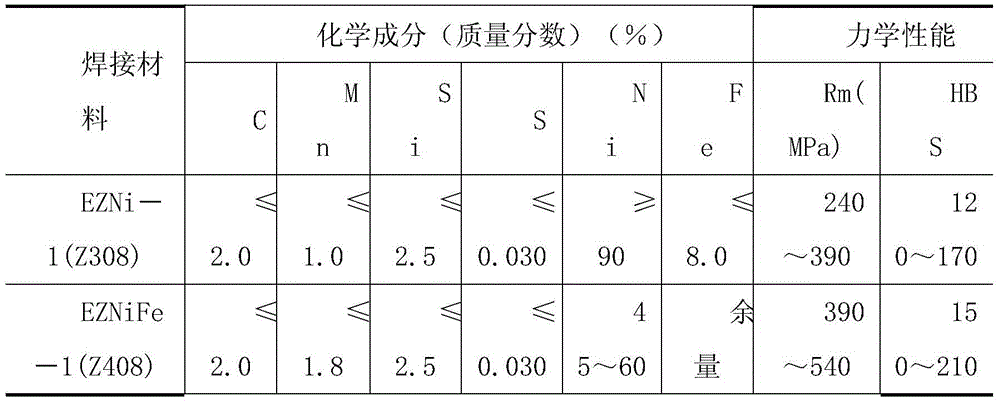

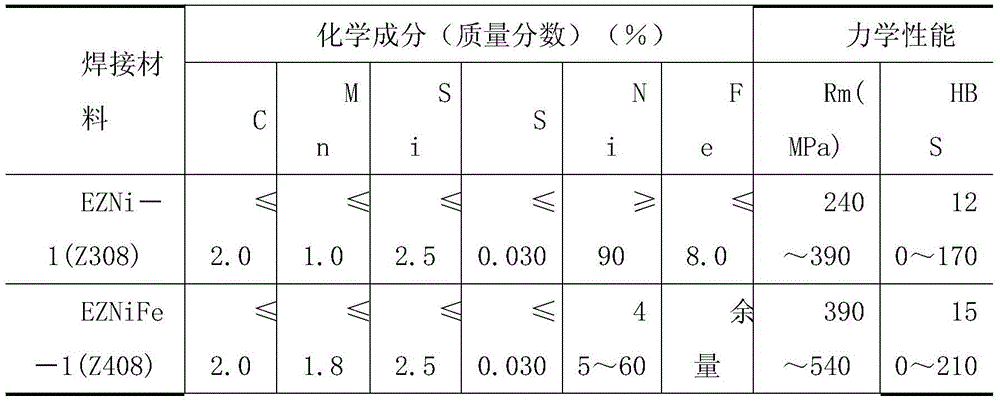

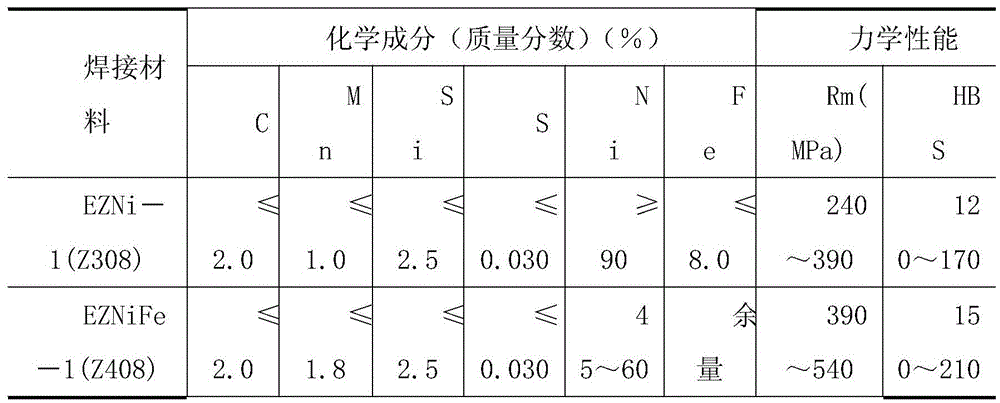

[0019] 1. Electrode arc welding is used, and the welding material is nickel-based electrode EZNi-1 (Z308) or nickel-iron alloy electrode EZNiFe-1 (Z408);

[0020] 2. Preheating before welding, the preheating temperature is 120~150℃;

[0021] 3. Use small line energy and narrow bead welding operation to reduce the dilution rate and reduce the width of the white layer in the semi-melting zone;

[0022] 4. Take measures such as short section welding, intermittent welding, scattered welding and hammering the weld immediately after welding to reduce welding stress;

[0023] 5. Choose a reasonable welding direction and sequence. The principle of welding from the part with high rigidity to the part with small rigidity should be mastered. When repairing cracks, the welding direction is segmented welding from the end of the closed crack to the open end of the crack;

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com