Welding method for stainless steel one-side welding double-side forming

A technology of single-sided welding and double-sided welding, which is applied in the field of steel welding, can solve the problems of high cost, achieve beautiful shape, reduce welding deformation and carburizing, and reduce welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

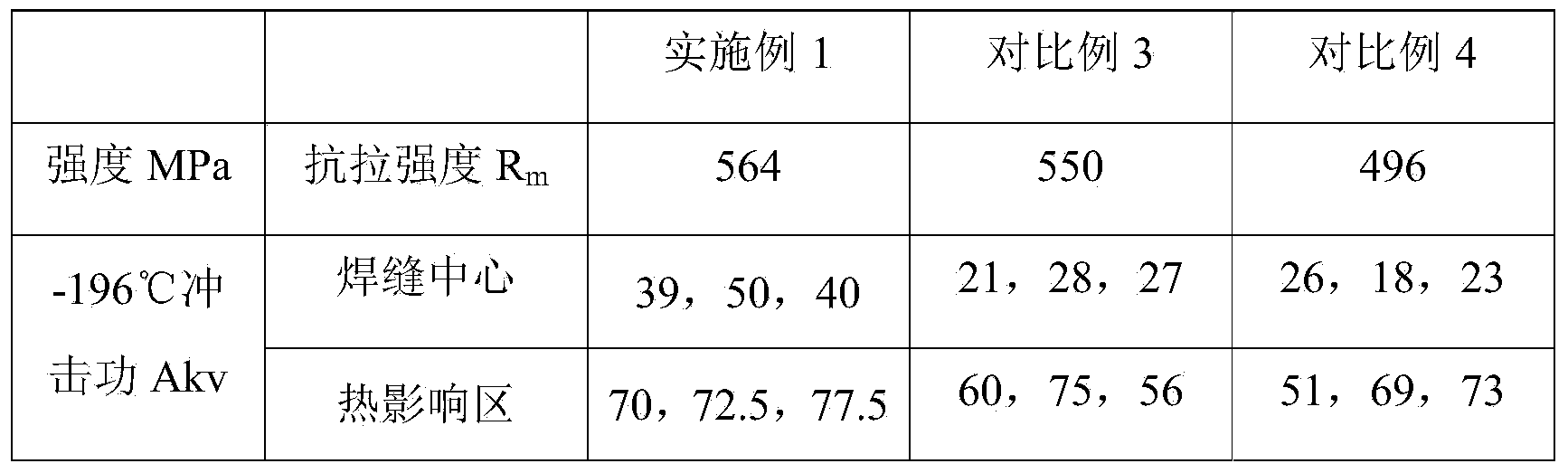

[0025] This embodiment provides a welding method for single-sided welding and double-sided forming of S30408 stainless steel, the method comprising the following steps:

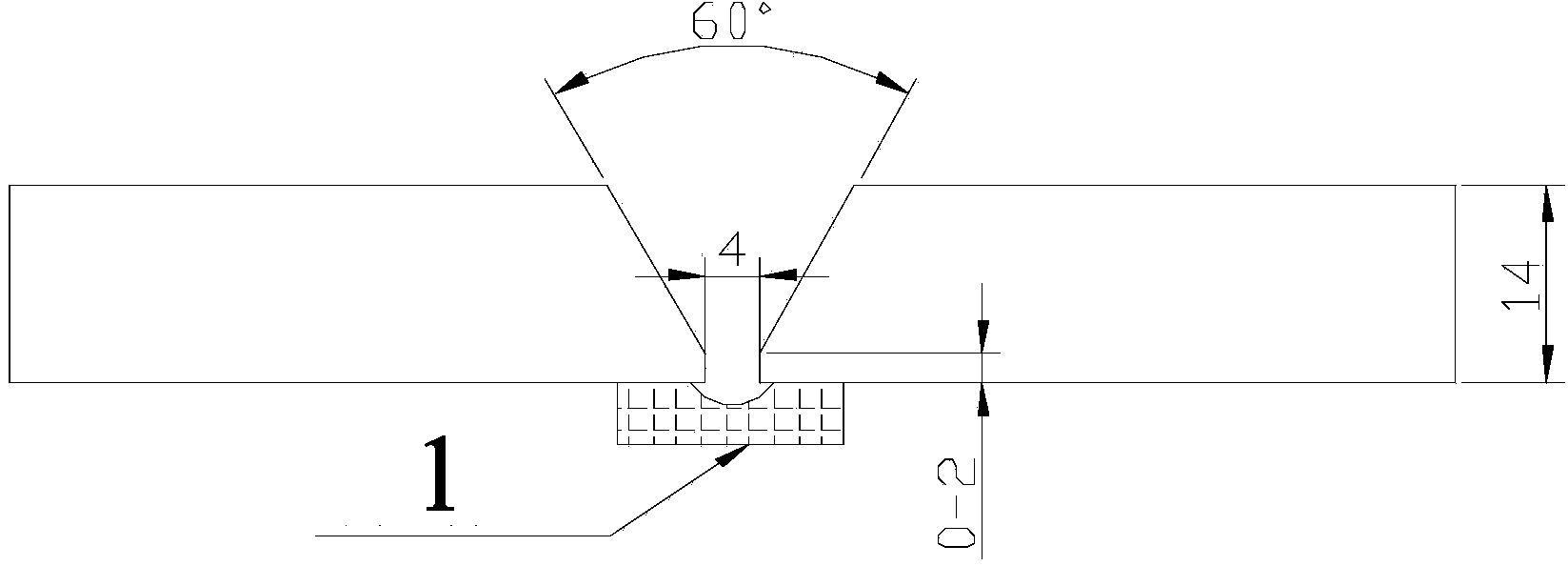

[0026] 1) The groove adopts a unilateral V-shaped groove, the groove angle is 60°, and the groove gap is 4mm; the back of the groove adopts a ceramic liner 1;

[0027] 2) The front of the groove is made of argon arc welding with self-shielding argon arc welding wire with coating, and then the cover is filled by electrode arc welding; the welding process parameters of argon arc welding are welding current 125-130A, arc voltage 12-14V , welding speed 14cm / min, welding heat input 8KJ / cm; the technological parameters of described electrode arc welding are welding current 150~160A, arc voltage 22~24V, welding speed 8cm / min, welding heat input 25KJ / cm, The electrode baking system is 350℃×2h.

[0028] The electrode type used in the step 2) is E308L-16, and its composition is as follows: C≤0.04%, Si≤0.9%, 0.5%≤Mn≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com