Method for welding thin layer iron nickel base alloy carbon steel composite tube

An iron-nickel-based alloy, welding method technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve problems such as incompatibility, changes in metallographic structure and chemical composition, cracks, etc., to improve welding quality and avoid defects The formation of the structure, the effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The relative welding of bimetal composite pipes with an outer diameter of 168 mm is taken as an example to illustrate. The material of the base layer is L360NCS, the thickness of the base layer is 16 mm, the material of the inner lining layer is UNS NO8028, and the thickness of the inner lining layer is 1.5 mm.

[0028] According to the technical scheme of the present invention, it is implemented according to the following steps:

[0029] The specific welding main parameters of Embodiment 1 are shown in Table 1.

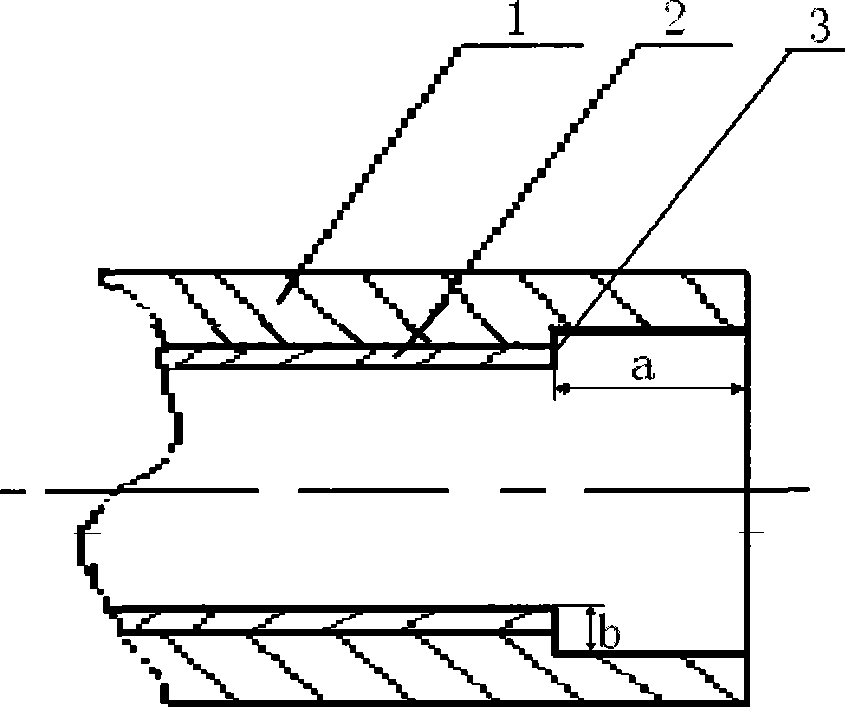

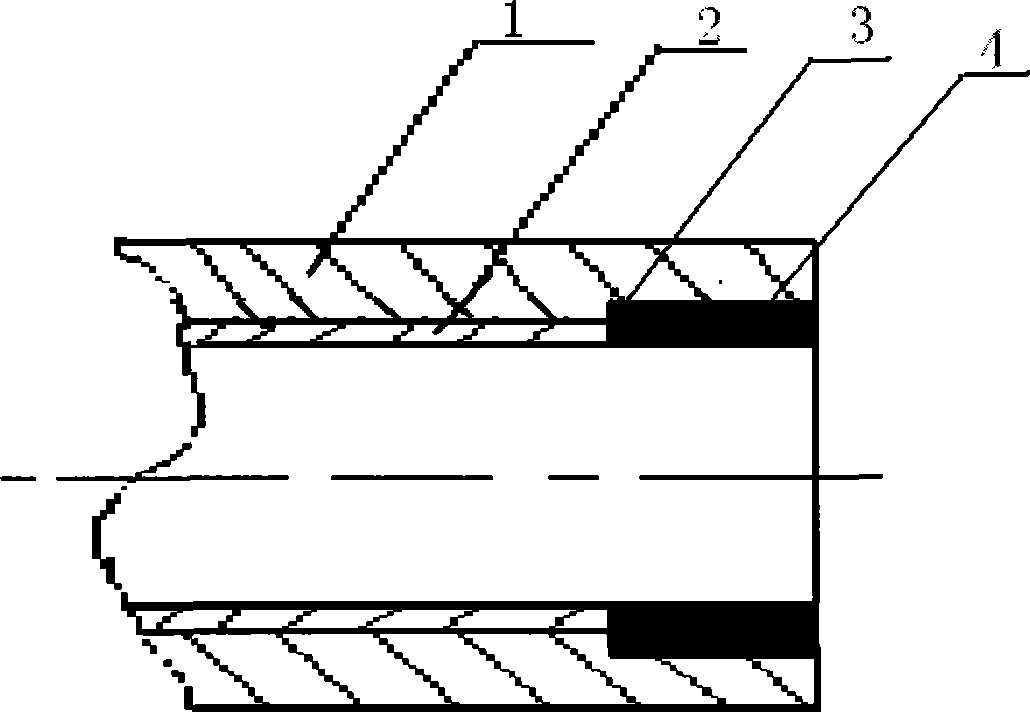

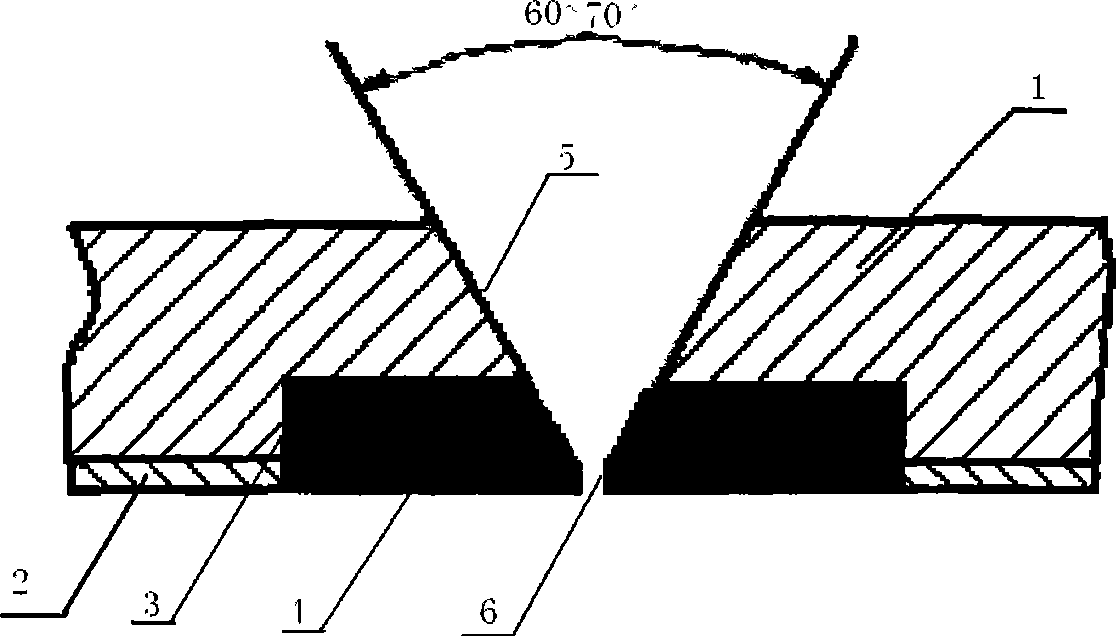

[0030] (1) Step processing: A step 3 is processed at the ends of two bimetallic composite pipes to be welded by machining methods (such as figure 1 shown), the width a of the step is twice the wall thickness of the base layer 1, namely 32 millimeters, and the height of the step is three times the thickness of the lining layer 2, namely 4.5 millimeters. After the steps are processed, use a polishing machine to remove the burrs, and use acetone to clean the oi...

Embodiment 2

[0040] The relative welding of bimetal composite pipes with an outer diameter of 114 mm is taken as an example for illustration. The material of the base layer is L360QC, the thickness of the base layer is 12mm, the material of the inner lining layer is UNS NO8825, and the thickness of the inner lining layer is 0.5mm.

[0041] According to the technical scheme of the present invention, it is implemented according to the following steps:

[0042] The main welding parameters are shown in Table 2.

[0043] (1) Step processing: A step 3 is processed at the ends of two bimetallic composite pipes to be welded by machining methods (such as figure 1 shown), the width a of the step is 3 times the thickness of the base layer, that is 36 mm, and the height of the step is 6 times the thickness of the lining layer, that is 3 mm. After the steps are processed, use a polishing machine to remove the burrs, and use acetone to clean the oil stains on the steps.

[0044] (2) Seal welding: sur...

Embodiment 3

[0053] The relative welding of bimetal composite pipes with an outer diameter of 114 mm is taken as an example for illustration. The material of the base layer is L360QC, the thickness of the base layer is 12 mm, the material of the inner lining layer is UNS NO6985, and the thickness of the inner lining layer is 1.0 mm.

[0054] According to the technical scheme of the present invention, it is implemented according to the following steps:

[0055] The main welding parameters are shown in Table 3.

[0056] (1) Step processing: A step 3 is processed at the ends of two bimetallic composite pipes to be welded by machining methods (such as figure 1 shown), the width a of the step is three times the thickness of the base layer, that is, 36 mm, and the height of the step is four times the thickness of the lining layer, that is, 4 mm. After the steps are processed, use a polishing machine to remove the burrs, and use acetone to clean the oil stains on the steps.

[0057] (2) Seal w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com