Simulative training device for manual arc welding operation

A technology of manual arc welding and welding torches, applied in teaching models, educational tools, instruments, etc., can solve problems such as adverse effects on welders' health, strong arc light, and consumption of large welding rod power resources, so as to reduce training costs and improve training efficiency. The effect of improving welding skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with accompanying drawing:

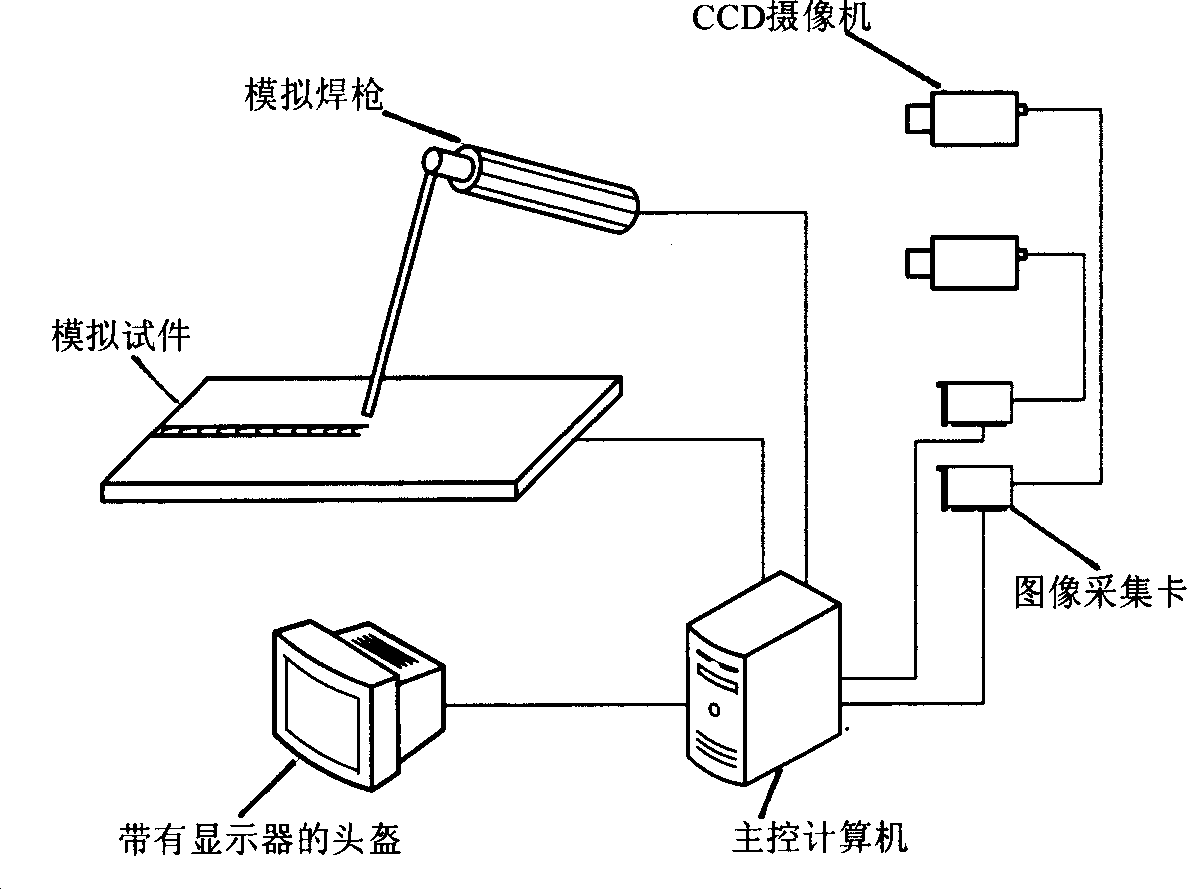

[0035] The present invention adopts virtual reality technology as the core of the platform. In essence, virtual reality is an advanced computer user interface. means to maximize the convenience of user operations, thereby reducing the burden on users and improving the work efficiency of the entire system. Usually the user wears a headset (a head-mounted display used to display stereoscopic images) and holds a sensory glove, as if in a hallucinatory world, roaming in the virtual environment and allowing the manipulation of "objects" in it.

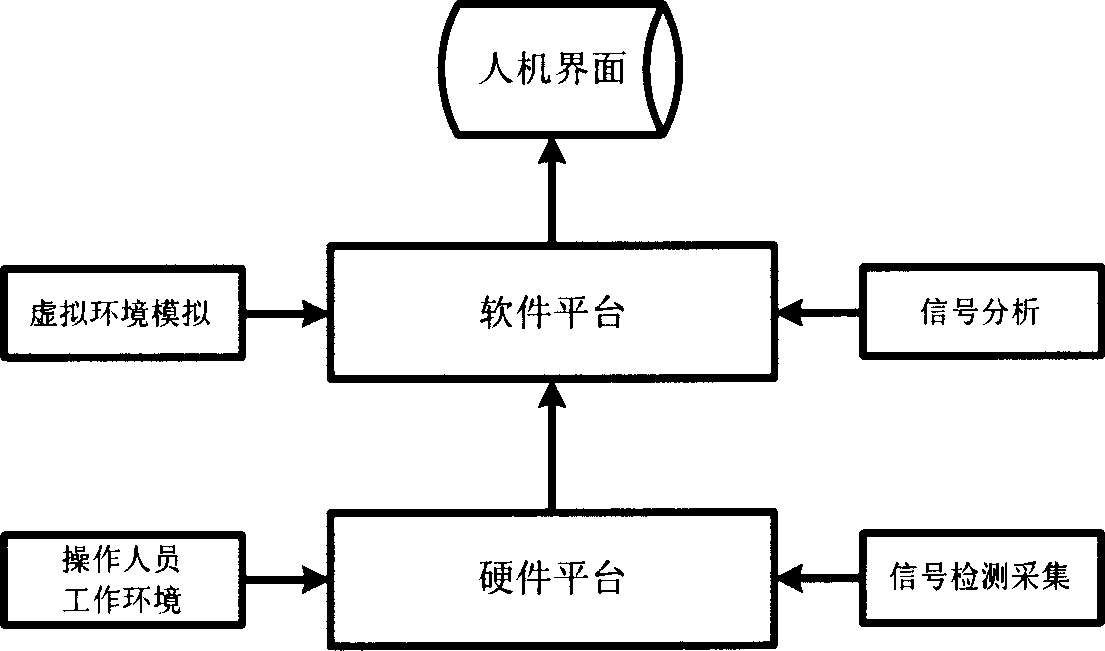

[0036] figure 1 It is the overall principle block diagram of the system, which is divided into two parts: the hardware platform and the software platform. The work of the software platform is to analyze and calculate the signals collected by the hardware platform, and reconstruct the 3D scene. This 3D scene interacts with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com