Welding operation simulator for CO2 gas shield arc welding

A gas shielded welding and simulator technology, which is applied to simulators, simulation devices and instruments of space navigation conditions, etc., to reduce training costs and improve welding skills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

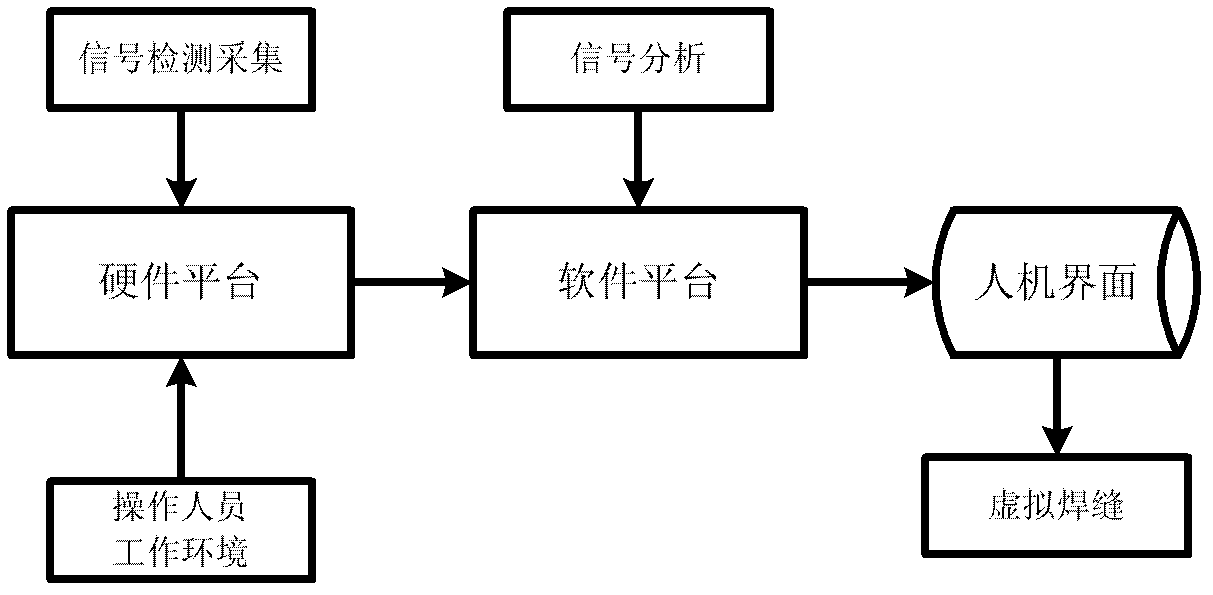

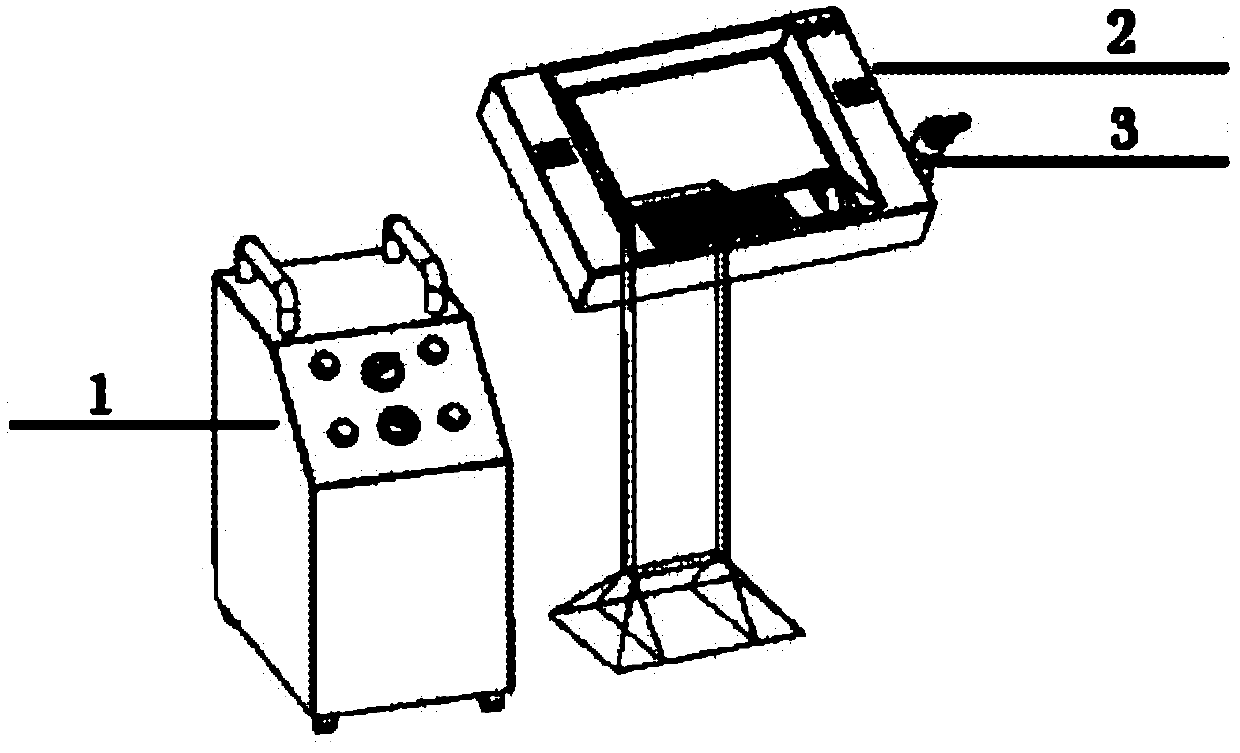

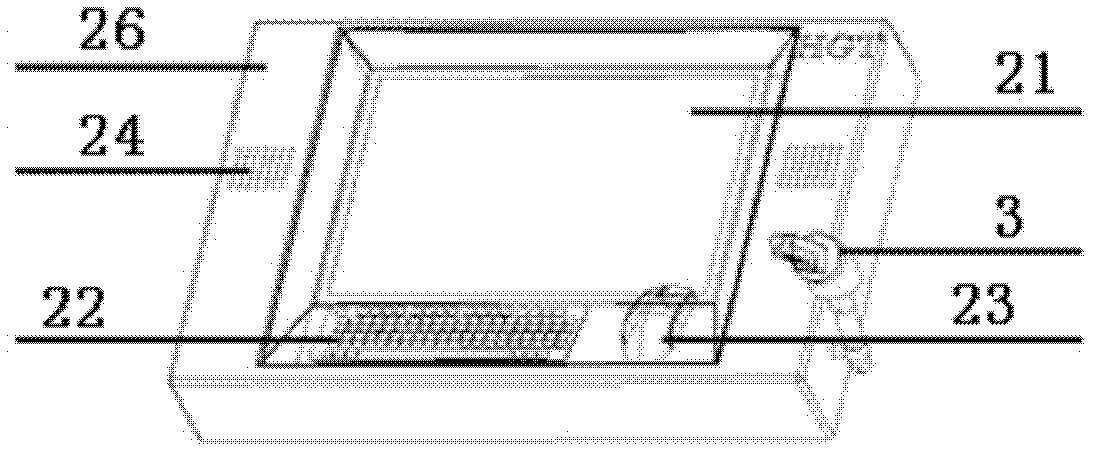

[0024] The present invention combines technologies such as virtual reality, sensor technology and visual simulation, in the research of CO 2 On the basis of the principle and characteristics of gas shielded welding operation, a two-dimensional mouse-type detection system based on touch screen is designed. In addition, through the inductive proximity switch and inclination sensor installed in the simulated welding torch, the distance between the end of the welding torch and the touch screen (that is, the length of the simulated arc) and the inclination data of the welding torch are obtained, and finally the detection of the five degrees of freedom of the welding torch is completed. Under a specific molten pool model, through the processing and analysis of the above welding parameters collected, a real-time virtual welding scene based on OpenGL is generated, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com