Argon-arc welding operation analog training device

A technology of argon arc welding and detection equipment, applied in teaching models, educational tools, instruments, etc., can solve problems such as strong arc light, adverse effects on welders' health, and consumption of power resources of large welding rods, so as to improve welding skills and reduce training costs , Improve the effect of training efficiency

Inactive Publication Date: 2010-11-10

XI AN JIAOTONG UNIV

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the actual training stage of manual welding in the past, the training was carried out by the master leading the apprentice. The training effect was affected by human factors such as the teacher's operation level and expression ability, and the shortage of teachers has already appeared in the current welding training field. At the same time, the welding operation also has high requirements on the site, equipment and environment. The training process needs to consume a lot of welding rods, test plates, and considerable power resources. Not only that, but as we all know, the welding environment is relatively harsh. A large amount of smoke and dust and strong arc light are very likely to have a negative impact on the health of welders. For those who are new to welding training, the harsh working environment is likely to have a negative impact on their psychology, which is not conducive to follow-up training plans

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

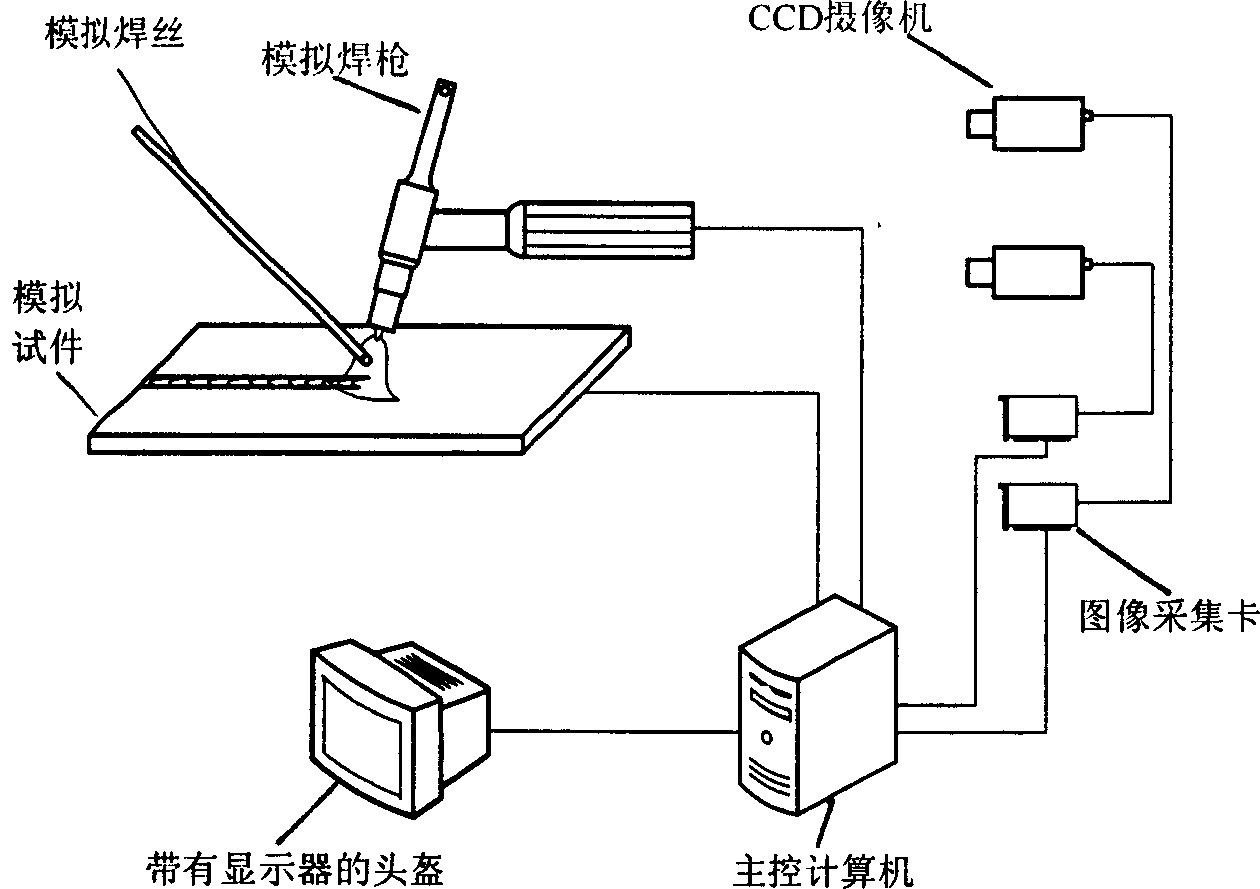

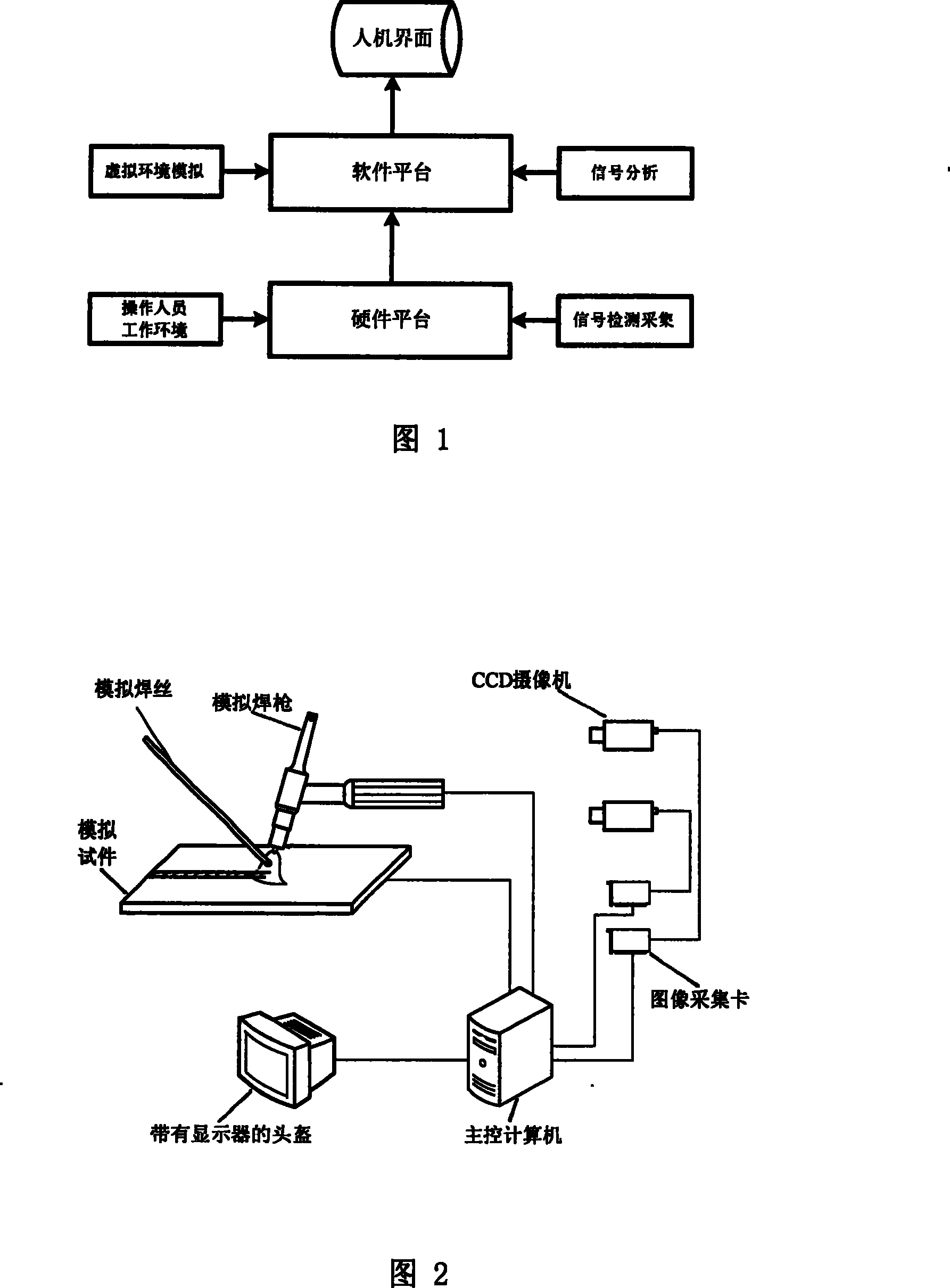

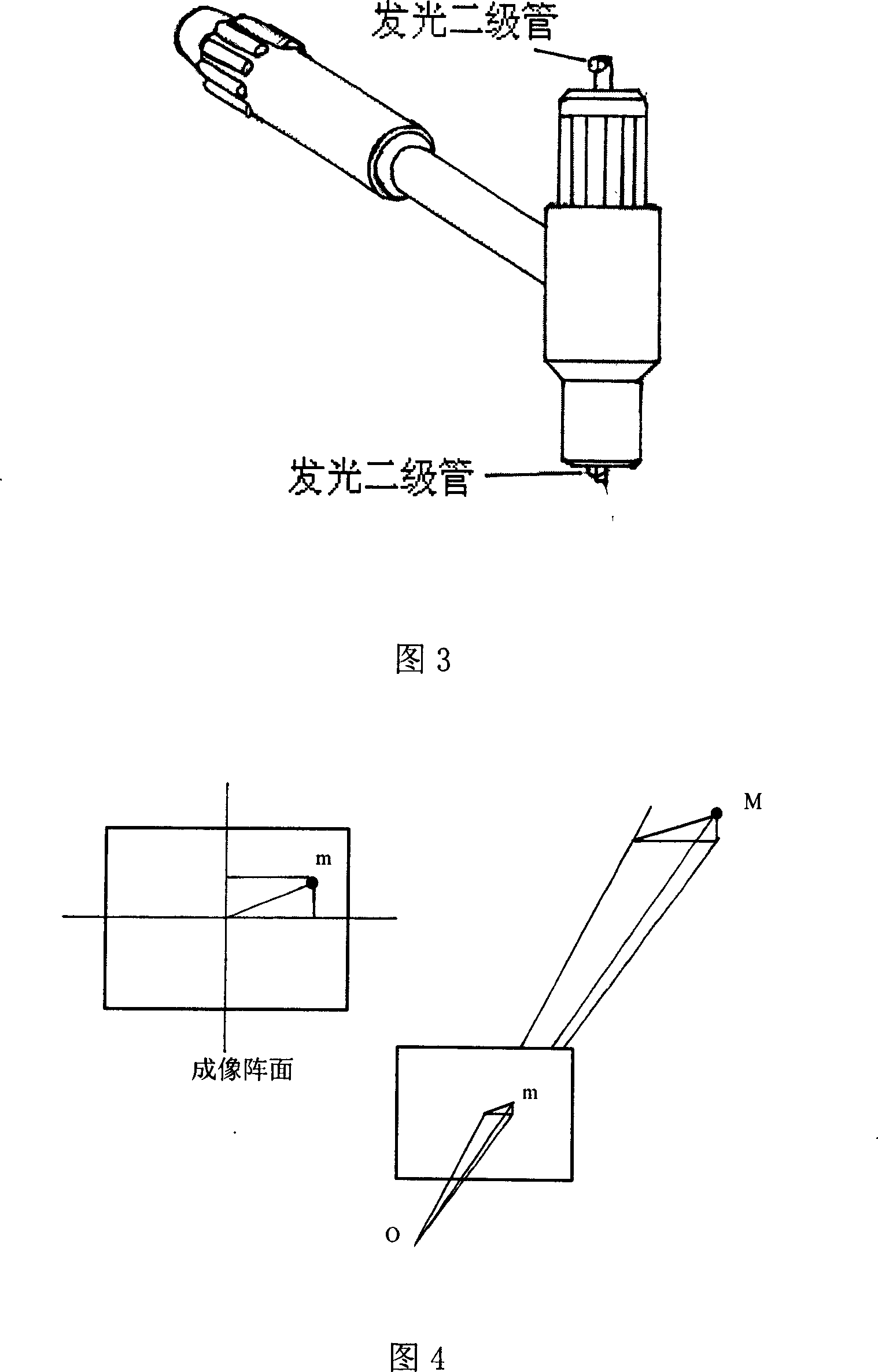

The related simulation training device for Ar-arc welding operation comprises: a simulation torch with arc-striking switch, a simulation solder wire, some pieces, a master-control computer, a detector for the torch and wire position, and a helmet with a display connected with former computer to display the welding process menu. This invention applies new devices to improve current training with less cost and well efficiency.

Description

Argon arc welding operation simulation training device technical field The invention relates to a welding operation simulation training device, in particular to argon arc welding welding operation simulation training device. Background technique Welding is a very popular material processing method. It is widely used in various enterprise production occasions. Typical examples are automobile manufacturing, pressure vessel manufacturing, shipbuilding, etc. Although there are many automatic welding methods that are relatively mature and more and more applied. However, due to the convenience and flexibility of use, manual welding methods such as argon arc welding still have an irreplaceable role, such as welding of various pressure vessel pipes and various maintenance welding occasions. In the manual welding operation process, there are many factors that affect the welding quality, such as the selection of process parameters such as: current, voltage, electrode (welding wire)...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G09B19/24G09B25/00

Inventor 张建勋薛金保梁振新邹林陈小艺裴怡黄挺孙华孙懿敏

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com