Manual arc welding simulated welding gun

A technology of manual arc welding and welding torches, applied in the direction of teaching models, educational tools, instruments, etc., can solve problems such as unfavorable training programs, strong arc light, large quantities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are described in conjunction with accompanying drawings:

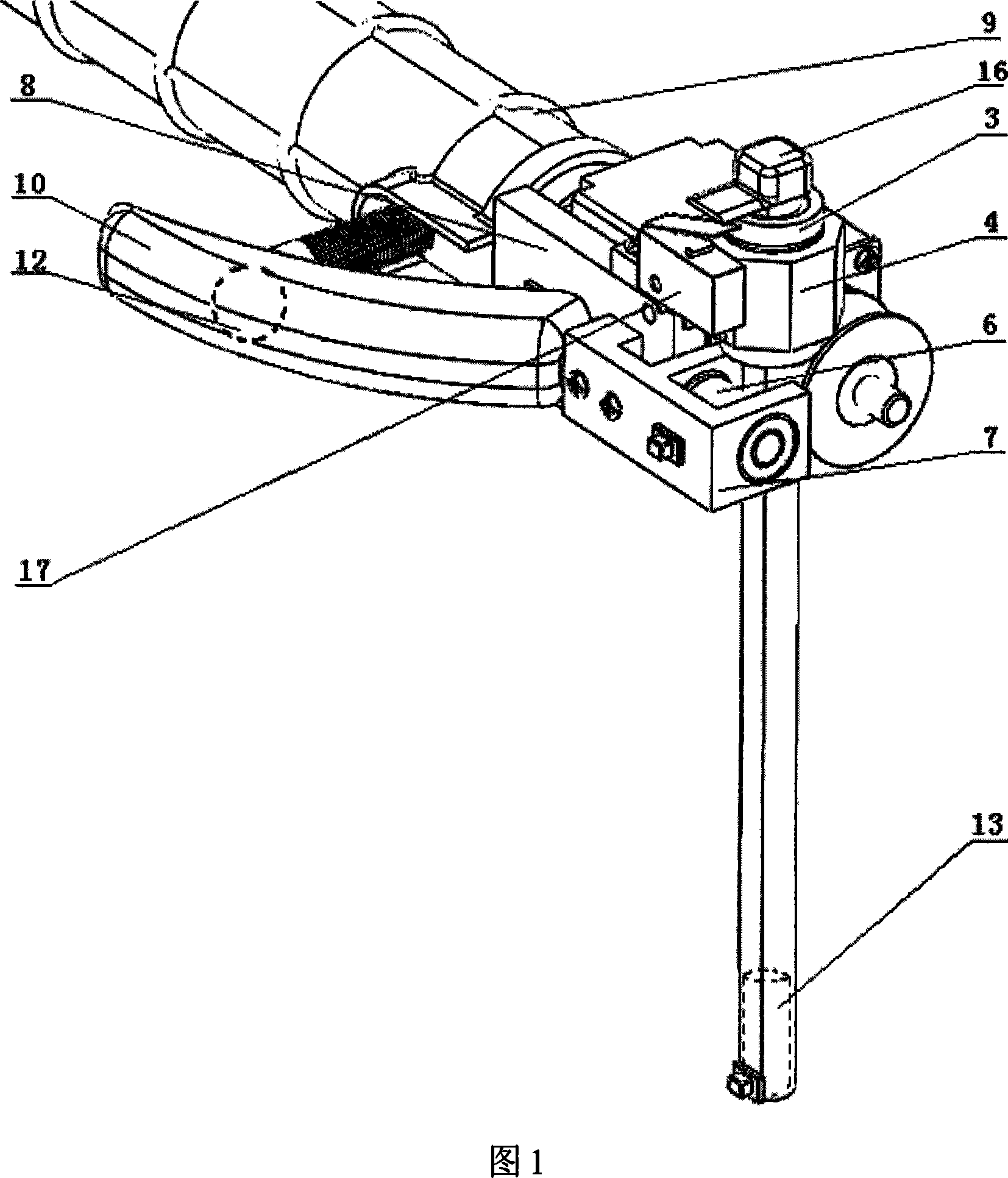

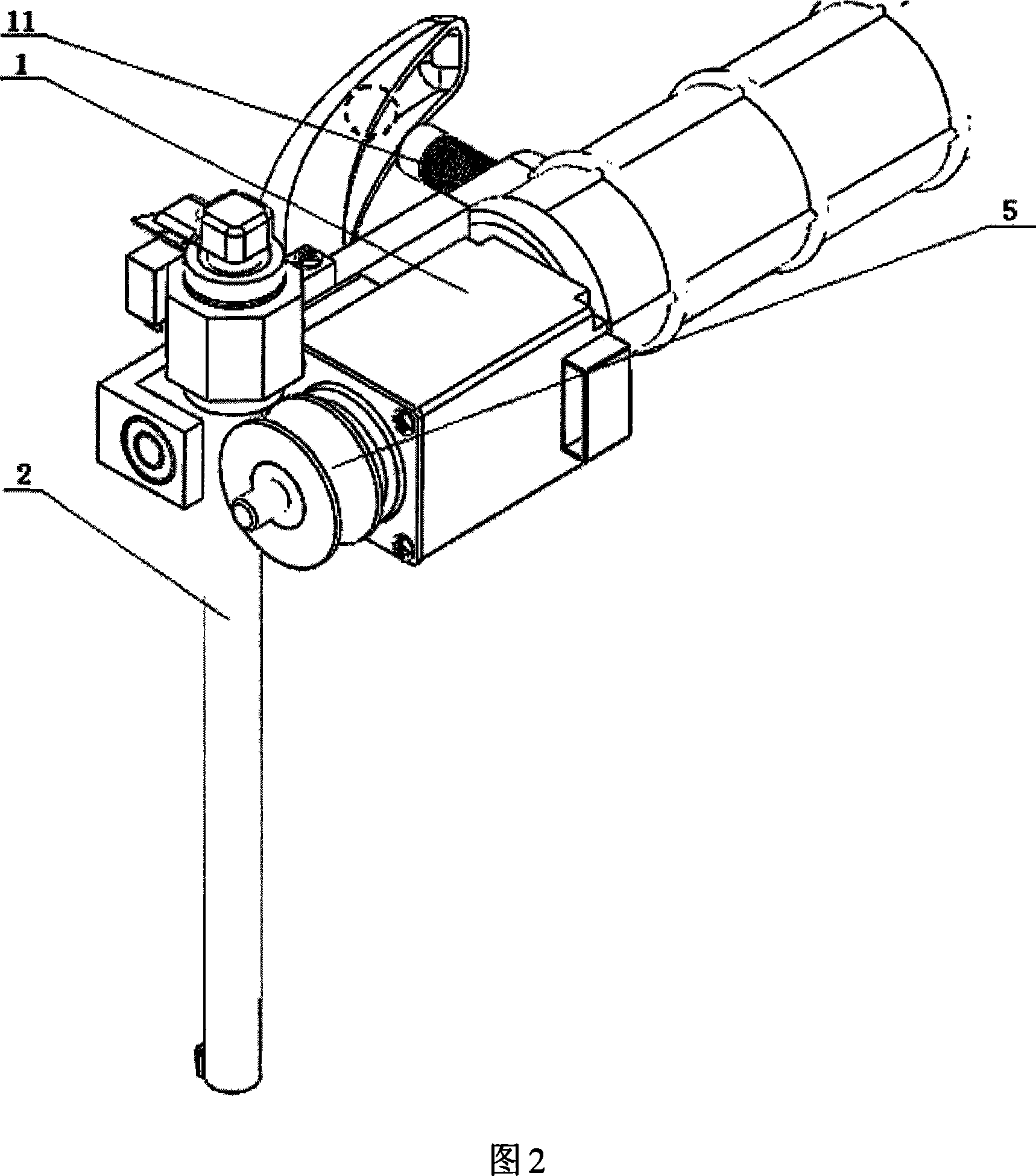

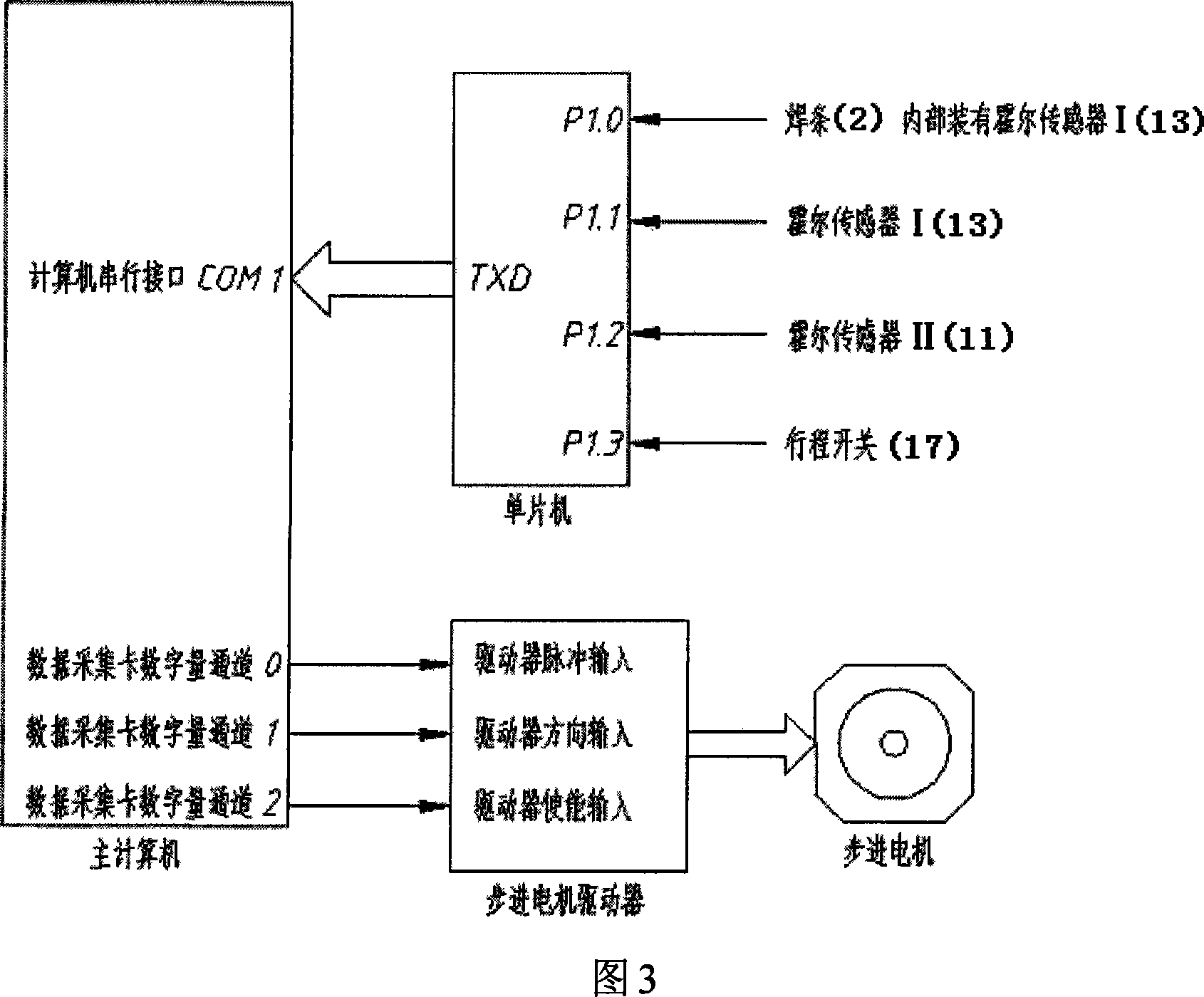

[0015] As shown in Figure 1, the present invention mainly is made of stepper motor 1, simulated electrode 2 and drive wheel 5, welding torch handle 9 and clamping handle 10, wherein, simulated electrode 2 is installed in the linear bearing 3, and drive wheel 5 and The driven wheel 6 frictionally clamps the welding rod from both sides; the linear bearing 3 is installed in the bearing seat 4, the bearing seat 4 is connected with the motor seat 8 through screws, and the driving wheel 5 is installed on the motor shaft of the stepping motor 1, The stepper motor 1 is installed on the motor base 8, the driven wheel 6 is installed in the roller support 7, the support 7 is connected with the motor base 8 through screws, and the clamping part installed as a whole is finally inserted into the welding torch handle 9 as a whole middle. The simulated welding rod 2 is made of stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com