Method for preventing overlaying sealing surface from cracking

A sealing surface and crack technology, which is applied in the field of preventing cracks on the sealing surface of surfacing welding, can solve problems such as cracks, seriousness, and restrictions, and achieve the effects of simplifying the process, improving production efficiency, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

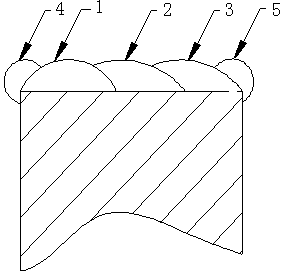

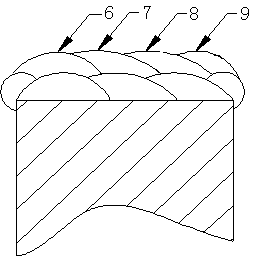

Image

Examples

Embodiment 1

[0022] 1. The welding equipment is DC arc welding machine. The welding power supply has a rated welding current of 350 amps.

[0023] 2. Overlay welding of cast steel valve body. Before the surfacing welding, the surface of the surfacing welding part of the cast steel valve body is polished, and the metallic luster can be seen; the surface of the workpiece must not have oil or moisture; after each layer of surfacing welding, a wire brush is required to remove the oxides on the surface of the surfacing layer.

[0024] 3. The transition layer electrode meets the requirements of GB / T983-2012 "Stainless Steel Electrode". Drying was carried out, and the drying temperature was 100°C. When welding, the workpiece is connected to the negative pole of the power supply, and the welding wire is connected to the positive pole of the workpiece.

[0025] 4. When welding, the ambient temperature is 5°C, and there is no preheating before welding.

[0026] 5. First surfacing the transition ...

Embodiment 2

[0031] 1. The welding equipment is DC arc welding machine. The welding power supply has a rated welding current of 350 amps.

[0032] 2. Overlay welding on the cast steel valve port. Before surfacing welding, the surface of the surfacing welding part of the cast steel valve port is polished, and the metallic luster can be seen; the surface of the workpiece must not have oil or moisture; after each layer of surfacing welding, steel wire brushes are required to remove oxides on the surface of the surfacing layer.

[0033] 3. The transition layer electrode meets the requirements of GB / T983-2012 "Stainless Steel Electrode". Drying was carried out, and the drying temperature was 100°C. When welding, the workpiece is connected to the negative pole of the power supply, and the welding wire is connected to the positive pole of the workpiece.

[0034] 4. When welding, the ambient temperature is 10°C, and there is no preheating before welding.

[0035] 5. First surfacing the transit...

Embodiment 3

[0040] 1. The welding equipment is DC arc welding machine. The welding power supply has a rated welding current of 350 amps.

[0041] 2. Overlay welding on the track of a certain product. Before surfacing, the surface of the surfacing of the torpedo track is polished, and the metallic luster can be seen; the surface of the workpiece must not have oil or moisture; after each layer of surfacing, it is necessary to use a wire brush to remove oxides on the surface of the surfacing layer.

[0042] 3. The transition layer electrode meets the requirements of GB / T983-2012 "Stainless Steel Electrode". Drying was carried out, and the drying temperature was 100°C. When welding, the workpiece is connected to the negative pole of the power supply, and the welding wire is connected to the positive pole of the workpiece.

[0043] 4. When welding, the ambient temperature is 10°C, and there is no preheating before welding.

[0044] 5. First surfacing the transition layer, the welding metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com