Pipeline welding method

A welding method and pipeline technology, which is applied in welding equipment, welding/welding/cutting items, pipeline systems, etc., can solve problems such as difficult quality assurance and stability, and achieve the effect of suppressing the tendency of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

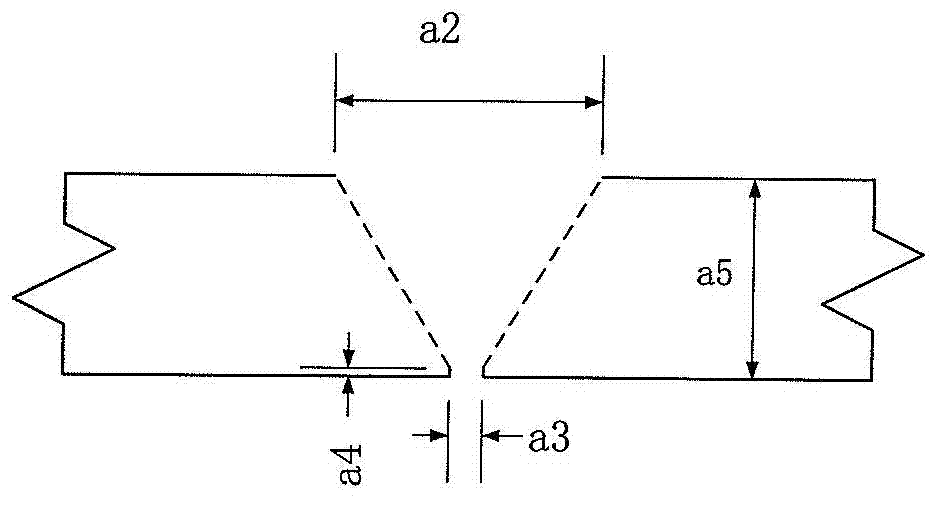

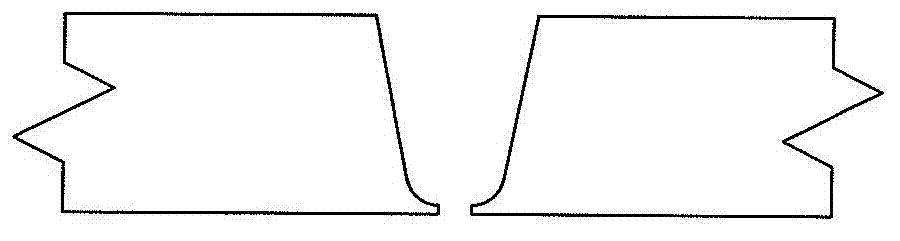

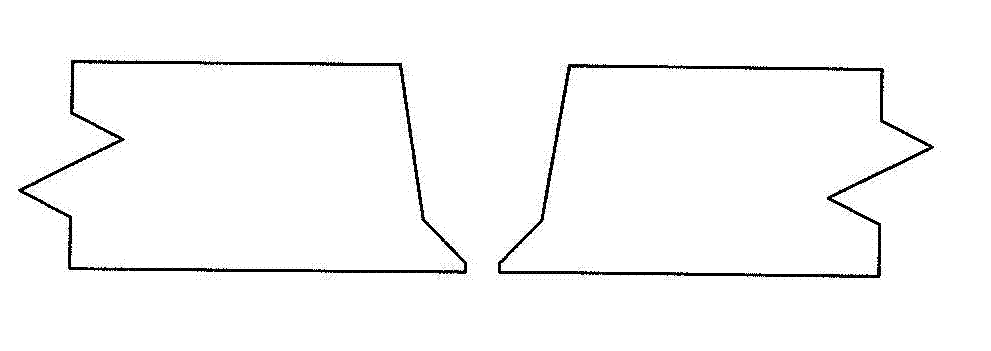

Method used

Image

Examples

Embodiment 1

[0071] On an ultra-deepwater semi-submersible drilling platform, the high-pressure mud pipeline used is: ASTM A519Gr.4130 material, and the supply state is usually quenched and tempered. The chemical composition range and mechanical performance requirements specified in ASTM specifications are shown in Table 1 and Table 2 .

[0072] Table 1 Chemical composition range of ASTM A519Gr.4130 (%)

[0073] steel grade

C

mn

Cr

Mo

P

S

Si

ASTM A519Gr.4130

0.28-0.33

0.40-0.60

0.80-1.10

0.15-0.25

≤0.04

≤0.04

0.15-0.35

[0074] Table 2 Typical mechanical properties of ASTM A519Gr.4130

[0075] steel grade

state

Tensile (MPa)

Yield (MPa)

Elongation(%)

ASTM A519Gr.4130

Conditioning

724

586

20%

[0076] According to the requirements of offshore platform construction specifications, additional impact toughness requirements are req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com