Printing and dyeing wastewater treatment system

A printing and dyeing wastewater treatment system technology, applied in textile industry wastewater treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effect of stable effluent water quality and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

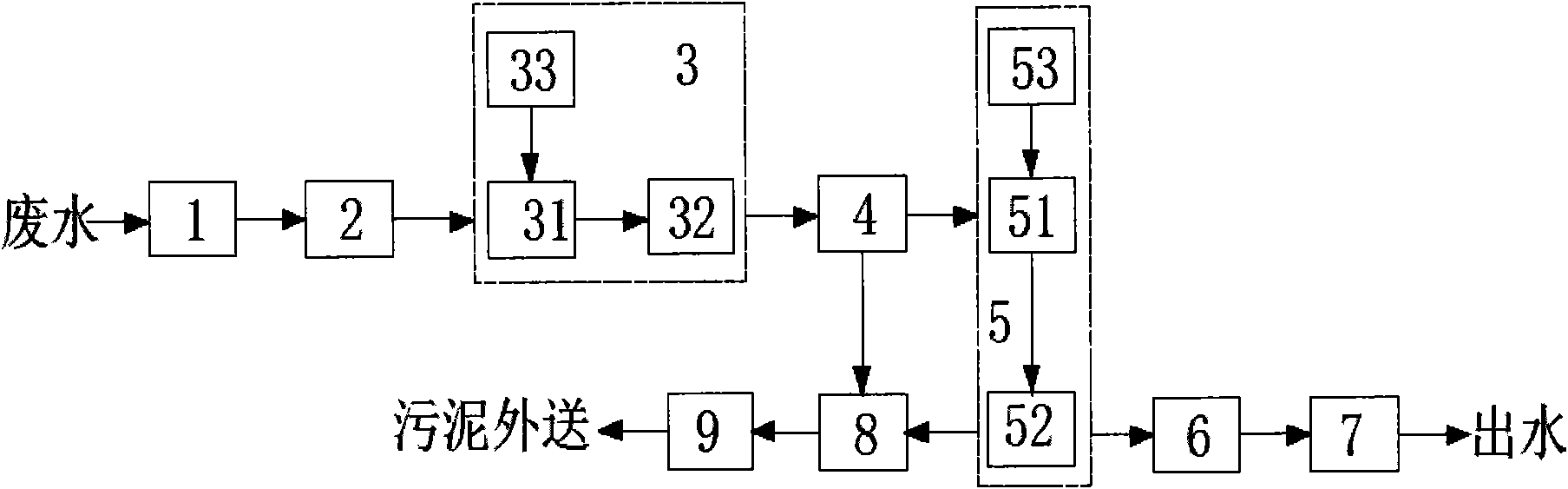

[0019] Such as figure 1 As shown, a printing and dyeing wastewater treatment system consists of a regulating tank 1, a lifting pump 2, a coagulation system 3, a primary sedimentation tank 4, a contact oxidation precipitation system 5, a sand filter 6, an activated carbon adsorption tank 7, a sludge pump 8, and a sewage The mud thickening pool consists of 9 nine parts.

[0020] The present invention will be described in further detail in conjunction with the accompanying drawings.

[0021] A printing and dyeing wastewater treatment system consists of the following parts in turn:

[0022] (1) Regulating pool 1: The waste water enters the regulating pool 1, where the water quantity is adjusted and the water quality is balanced. The multilateral water inlet method is adopted to make the wastewater flow out at the same time and not at the same time. The tank is equipped with an air-filled pipe. Due to the full agitation, the homogenization effect of the regulating tank 1 is fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com