Advanced dyeing wastewater treatment and reclaimed water reuse system and method thereof

A technology for advanced treatment of printing and dyeing wastewater, applied in textile industry wastewater treatment, biological water/sewage treatment, degassed water/sewage treatment, etc. Achieve the effects of stable and reliable operating costs, automatic control, and pollution elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

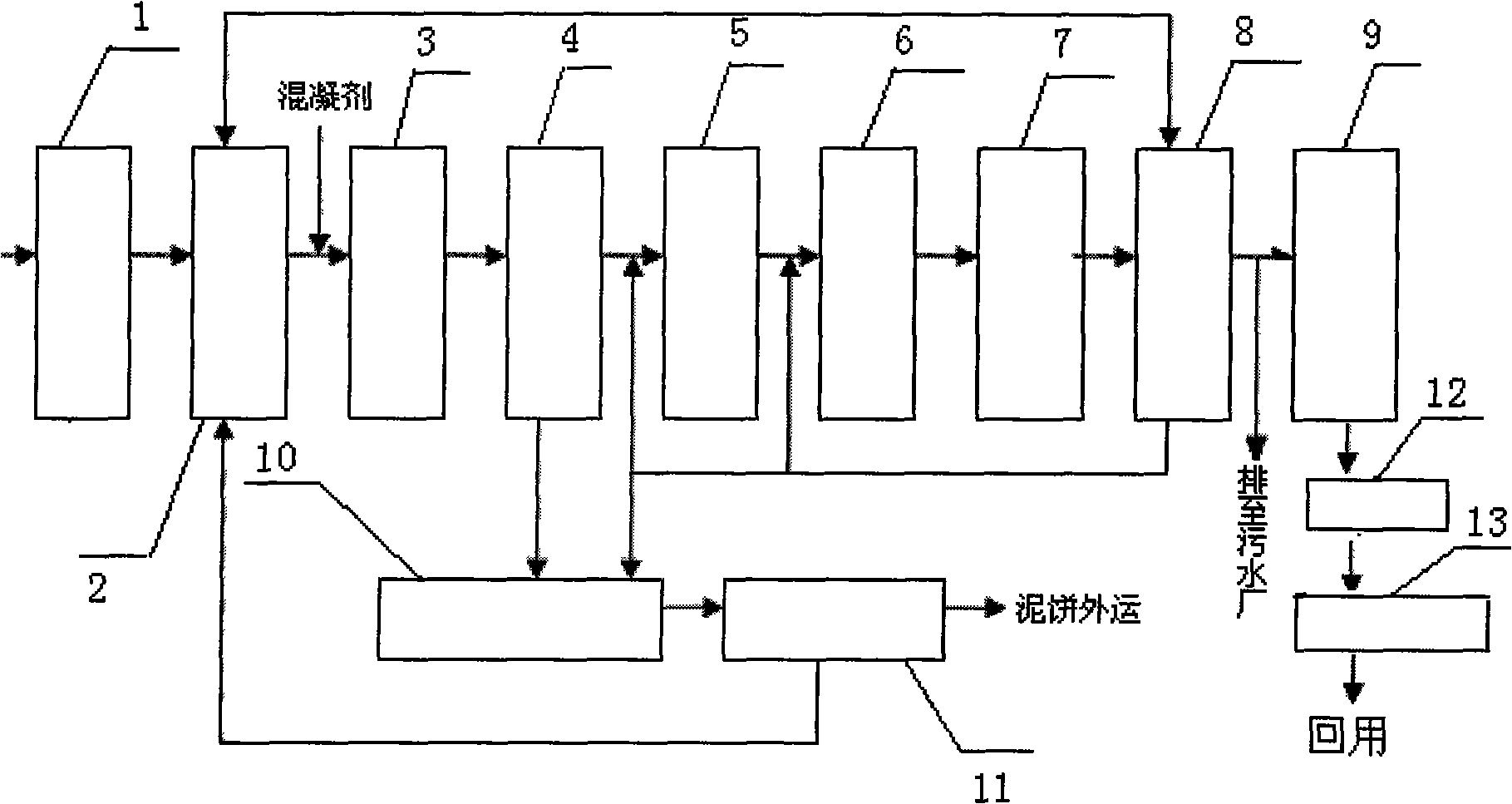

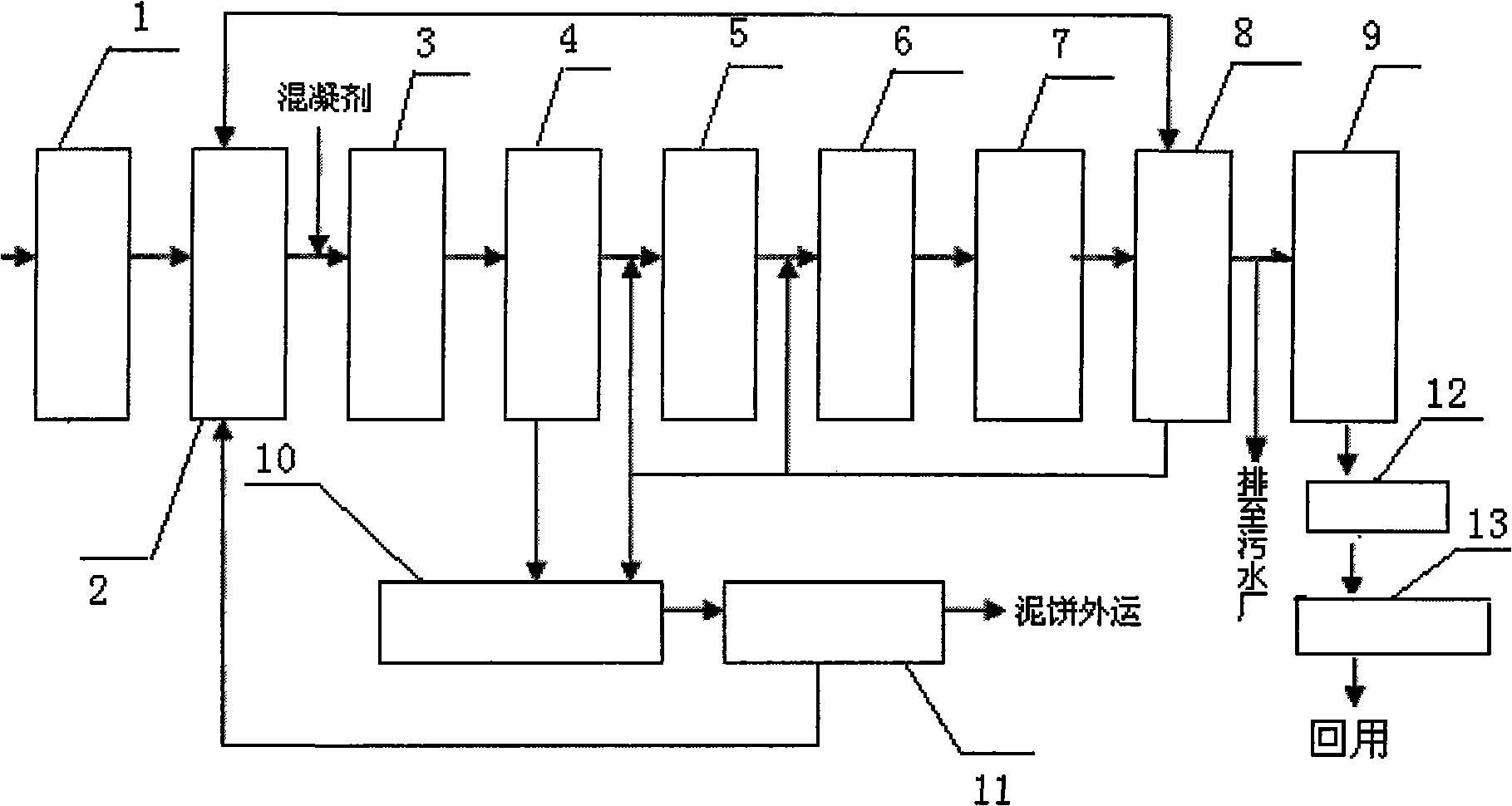

[0041] The printing and dyeing wastewater advanced treatment and reclaimed water reuse system is characterized in that it consists of a regulating tank (2), a coagulation tank (3), a pre-sedimentation tank (4), an acidification hydrolysis tank (5), a deep well (6), a degassing tank Pool (7), secondary settling tank (8), biologically activated carbon pool (9), sludge thickening tank (10), sludge dehydration tank (11), filter tank (12), and ozone oxidation tank (13).

[0042] Regulating pool: wastewater quality and quantity regulation;

[0043] Coagulation tank: used for coagulation of waste water, under rapid stirring, add coagulant to make coagulation reaction with waste water;

[0044] Pre-sedimentation tank: used for solid-liquid separation of wastewater after coagulation;

[0045] Acidification and hydrolysis tank: used for pretreated wastewater and microbial acidification and hydrolysis treatment. Aeration pipes are installed in the tank, and a small amount of aeration is...

Embodiment 2

[0063] The printing and dyeing wastewater advanced treatment and reclaimed water reuse system is characterized in that it consists of a regulating tank (2), a coagulation tank (3), a pre-sedimentation tank (4), an acidification hydrolysis tank (5), a deep well (6), a degassing tank Pool (7), secondary settling tank (8), biologically activated carbon pool (9), sludge thickening tank (10), sludge dehydration tank (11), filter tank (12), and ozone oxidation tank (13).

[0064] Regulating pool: wastewater quality and quantity regulation;

[0065] Coagulation tank: used for coagulation of wastewater dosing;

[0066] Pre-sedimentation tank: used for solid-liquid separation of wastewater after coagulation;

[0067] Acidification and hydrolysis tank: used for pretreated wastewater and microbial acidification and hydrolysis treatment. Aeration pipes are installed in the tank, and a small amount of aeration is used to mix wastewater and activated sludge, and maintain dissolved oxygen i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com