Carbon material-supported copper-cobalt bimetallic sulfide composite material and its preparation method and application in waste water treatment

A technology of composite materials and carbon materials, which is applied in the fields of chemical industry, environmental protection, and materials. It can solve the problems of limited pH value of catalytic environment and low catalytic activity, and achieve the effect of improving pollutant degradation ability, high pollutant degradation effect, and accelerated rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

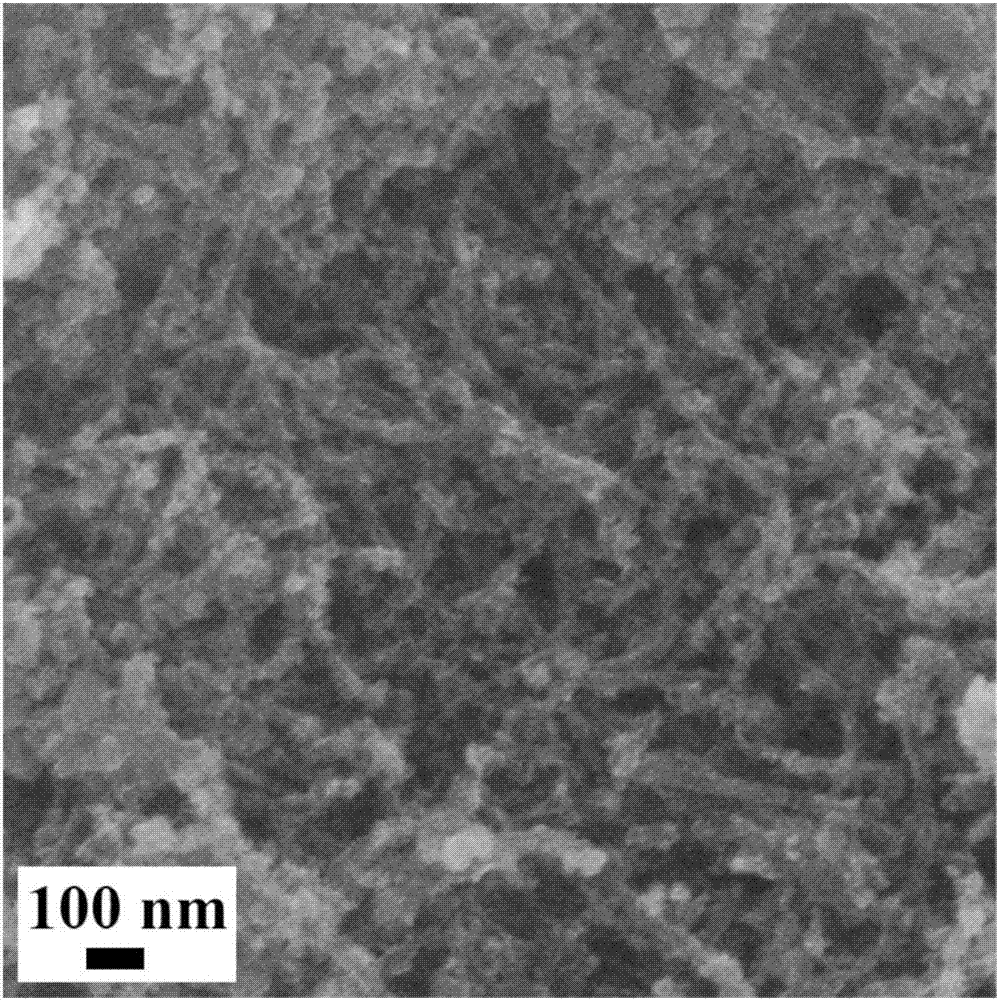

[0049] After the carbon nanotubes are treated with acid, acidified carbon nanotubes are obtained after washing with water, separation and drying. Take 20.0 mg of acidified carbon nanotubes, add 10.0 ml of distilled water, and perform ultrasonic dispersion treatment to obtain a carbon nanotube dispersion, which is set aside.

[0050] Add 64.5 mg of copper acetate monohydrate and 161.0 mg of cobalt acetate tetrahydrate into 10.0 ml of water, and stir to obtain a copper-cobalt aqueous solution, which is set aside.

[0051] Dissolve 32.0mg of sodium carbonate in 1.0ml of water to obtain sodium carbonate solution, set aside.

[0052] Dissolve 75.0 mg of cysteine in 10.0 ml of water to obtain a cysteine solution, set aside.

[0053] Prepare the required materials by a two-step method:

[0054] S1. Add the prepared carbon nanotube dispersion to the copper-cobalt aqueous solution, and add sodium carbonate solution; add 0.5ml triethylamine solution to obtain the mixed solution; t...

Embodiment 2

[0059] After the carbon nanotubes are treated with acid, acidified carbon nanotubes are obtained after washing with water, separation and drying. Take 20.0 mg of acidified carbon nanotubes, add 10.0 ml of distilled water, and obtain a carbon nanotube dispersion after ultrasonic dispersion treatment, which is set aside.

[0060] Add 64.5 mg of copper acetate monohydrate and 161.0 mg of cobalt acetate tetrahydrate into 10.0 ml of water, and stir to obtain a copper-cobalt aqueous solution, which is set aside.

[0061] Dissolve 155.3 mg of cysteine in 10.0 ml of water to obtain a cysteine solution, set aside.

[0062] Prepare the required materials by a one-step method:

[0063] Add the prepared carbon nanotube dispersion to the copper-cobalt aqueous solution, and then add the cysteine solution to obtain a mixed solution; transfer the mixed solution to a hydrothermal reactor, and perform a hydrothermal reaction at a temperature of 180°C for 12 hours . After the reaction, ...

Embodiment 3

[0067] After the carbon nanotubes are treated with an acid, acidified carbon nanotubes are obtained after washing with water, separation and drying. Take 20.0 mg of acidified carbon nanotubes, add 10.0 ml of distilled water, and perform ultrasonic dispersion treatment to obtain a carbon nanotube dispersion, which is set aside.

[0068] Add 64.5 mg of copper acetate monohydrate and 161.0 mg of cobalt acetate tetrahydrate into 10.0 ml of water, and stir to obtain a copper-cobalt aqueous solution, which is set aside.

[0069] Dissolve 32.0mg of sodium carbonate in 1.0ml of water to obtain sodium carbonate solution, set aside.

[0070] Dissolve 75.0 mg of cysteine in 10.0 ml of water to obtain a cysteine solution, set aside.

[0071] Prepare the required materials by a three-step method:

[0072] S1'. Add the prepared carbon nanotube dispersion to the copper-cobalt aqueous solution, then add the sodium carbonate solution; add 0.5ml triethylamine solution to the above dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com