Method for producing environment-friendly baking-free hollow brick from oil-containing sludge and construction wastes

A construction waste and hollow brick technology is applied in the field of industrial waste resource utilization and environmental protection energy, which can solve problems such as difficult disposal of oily sludge, reduce groundwater and soil opportunities, highlight environmental benefits, and reduce landfill loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

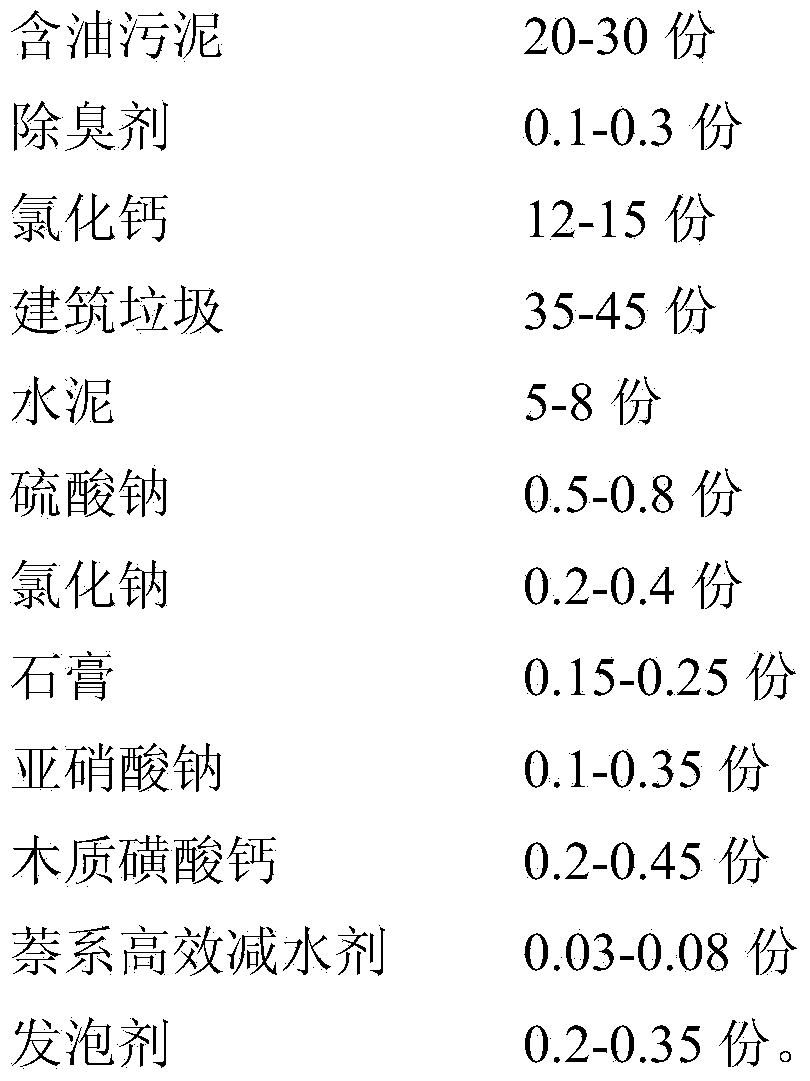

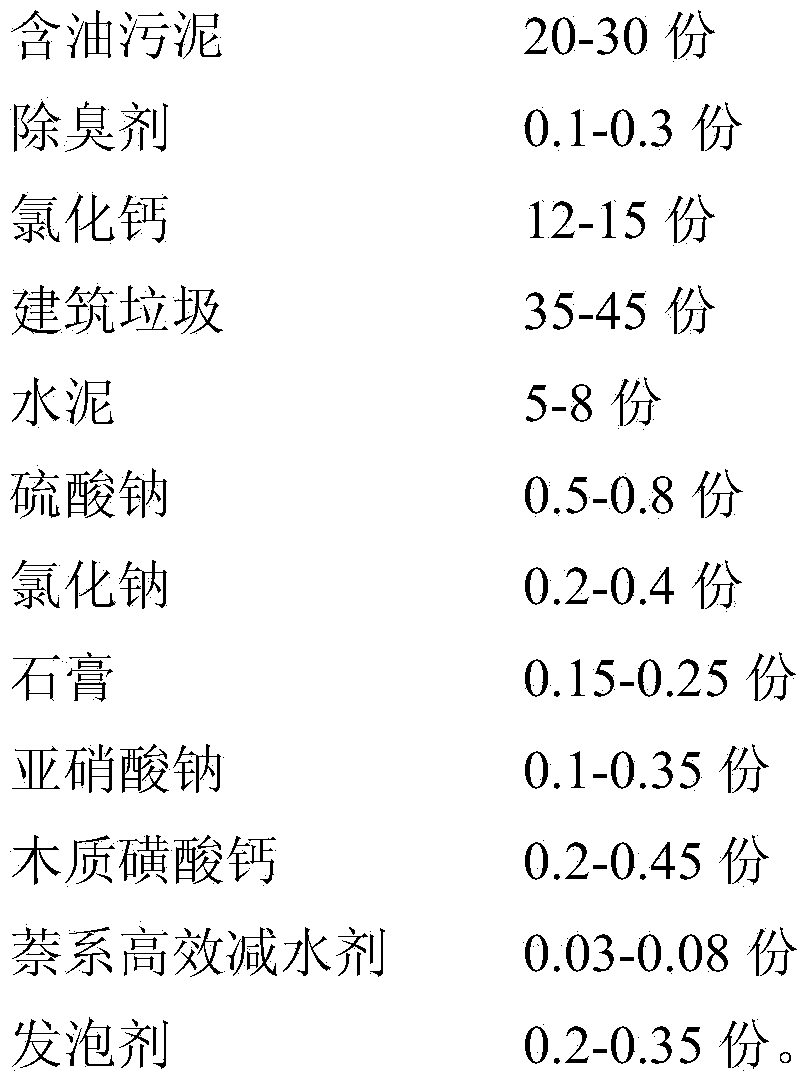

Method used

Image

Examples

Embodiment 1

[0028] Take 40kg of oily sludge from a petrochemical enterprise, with an oil content of 12.3% and a water content of 80%, add 0.2kg of sodium hypochlorite and 12kg of calcium chloride, and mix and stir for 5 minutes; take 60kg of recycled fine aggregate, 10kg of cement, and Calcium chloride 12kg, aluminum powder 0.4kg, sodium sulfate 1.0kg, sodium chloride 0.4kg, gypsum 0.25kg, sodium nitrite 0.2kg, calcium lignosulfonate 0.4kg and naphthalene superplasticizer 0.1kg through automatic feeding The system enters the mixing mixer and stirs evenly for 20 minutes; the mixture is made into a non-fired hollow brick with a specification of 390mm*190mm*190*mm under a pressure of 25MPa, and the finished product is made after natural curing for 20 days.

[0029] The average compressive strength of the 5 non-fired hollow bricks prepared by testing is 10.23Mpa, the flexural strength is 5.62Mpa, the relative moisture content is 27%, and the height of the water surface drop of the 3 bricks is ...

Embodiment 2

[0031] Take 50kg of oily sludge from a petrochemical enterprise, with an oil content of 14.1% and a water content of 76%, add 0.3kg of sodium hypochlorite and 15kg of calcium chloride, and mix and stir for 5 minutes; take 70kg of recycled fine aggregate, 13kg of cement, chlorine Calcium 15kg, aluminum powder 0.7kg, sodium sulfate 1.25kg, sodium chloride 0.6kg, gypsum 0.4kg, sodium nitrite 0.35kg, calcium lignosulfonate 0.5kg, naphthalene superplasticizer 0.1kg through the automatic feeding system Put it into the mixing mixer and stir evenly for 20 minutes; make the mixture under the pressure of 30MPa into a non-fired hollow brick with a specification of 390mm*190mm*190*mm, and make it into a finished product after natural curing for 20 days.

[0032] The average compressive strength of the 5 non-fired hollow bricks prepared by testing is 12.37Mpa, the flexural strength is 6.11Mpa, the relative moisture content is 22%, and the water surface drop height of the three bricks is not...

Embodiment 3

[0034]Take 40kg of oily sludge from petrochemical enterprises, with an oil content of 12.3% and a water content of 80%, add 0.2kg of sodium hypochlorite and 12kg of calcium chloride, and mix and stir for 5 minutes; take 60kg of recycled fine aggregate, 10kg of cement, chlorine Calcium 12kg, ferrosilicon alloy 0.4kg, sodium sulfate 1.6kg, sodium chloride 0.4kg, gypsum 0.25kg, sodium nitrite 0.2kg, calcium lignosulfonate 0.4kg, naphthalene superplasticizer 0.1kg through the automatic feeding system Enter the mixing mixer and stir evenly for 20 minutes; the mixture is made into a non-fired hollow brick with a specification of 390mm*190mm*190*mm under a pressure of 25MPa, and the finished product is made after natural curing for 20 days.

[0035] The average compressive strength of 5 unfired hollow bricks prepared by testing 5 pieces is 11.58Mpa, the flexural strength is 7.13Mpa, the relative moisture content is 19.7%, and the water surface drop height of the three bricks is not mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com