Preparation method of hydrated calcium silicate early strength agent and self-compacting concrete

A technology of self-compacting concrete and calcium silicate hydrate, which is applied in the field of building materials, can solve the problems of high production energy consumption, high price, and increased production cost of calcium silicate hydrate, and achieve the improvement of early strength and later strength, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

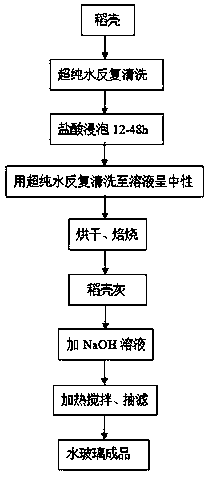

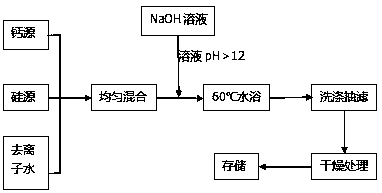

[0039] Such as figure 1 , 2 Shown, a kind of preparation method of calcium silicate hydrate accelerator, the method comprises the following steps:

[0040] Get silicon source:

[0041] (1) Choose rice husk as the silicon source, and wash the rice husk repeatedly with distilled water for 3 to 5 times;

[0042] (2) Soak the washed rice husks in 0.5-1mol / L hydrochloric acid solution for 12-48 hours, wash the rice husks repeatedly until the solution is neutral, and then filter out;

[0043] (3) Dry the rice husks cleaned in step (2) in a blast drying oven at 100°C for 24 h;

[0044] (4) Put the acidified pretreated rice husk in step (3) into a box-type resistance furnace, heat up from 25°C to 400-800°C at a heating rate of 10°C / min, roast for 1 hour, take it out, and grind it to obtain white rice husk ash ;

[0045] The rice husk is fully burned in an oxidizing environment at 400-800°C, especially at 400-800°C. The rice husk ash contains less carbon, has a larger specific sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com