Forsterite zirconia brick and producing method thereof

A technology of olivine zirconium brick and manufacturing method, which is applied in the field of refractory materials, can solve problems such as inconvenient design and production of kiln, erosion of glass kiln lattice body, deformation of lattice body, etc., and achieve the goals of eliminating chromium pollution, convenient design and construction, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The manufacture method of a kind of forsterite zirconium brick is as follows:

[0026] 1) Crushing and screening of raw materials: crush magnesia (MgO 95%) and forsterite sand in a crusher or a ball mill, and sieve through a 3mm sieve, a 1mm sieve and a 0.088mm sieve respectively to make a particle size of Magnesia and forsterite sand of 1mm to 3mm, magnesia and forsterite sand with a particle size of 0.088mm to 1mm, fine powder of magnesia and forsterite sand with a particle size of ≤0.088mm; zircon sand ( ZrO 65%) made particle size ≤ 0.088mm;

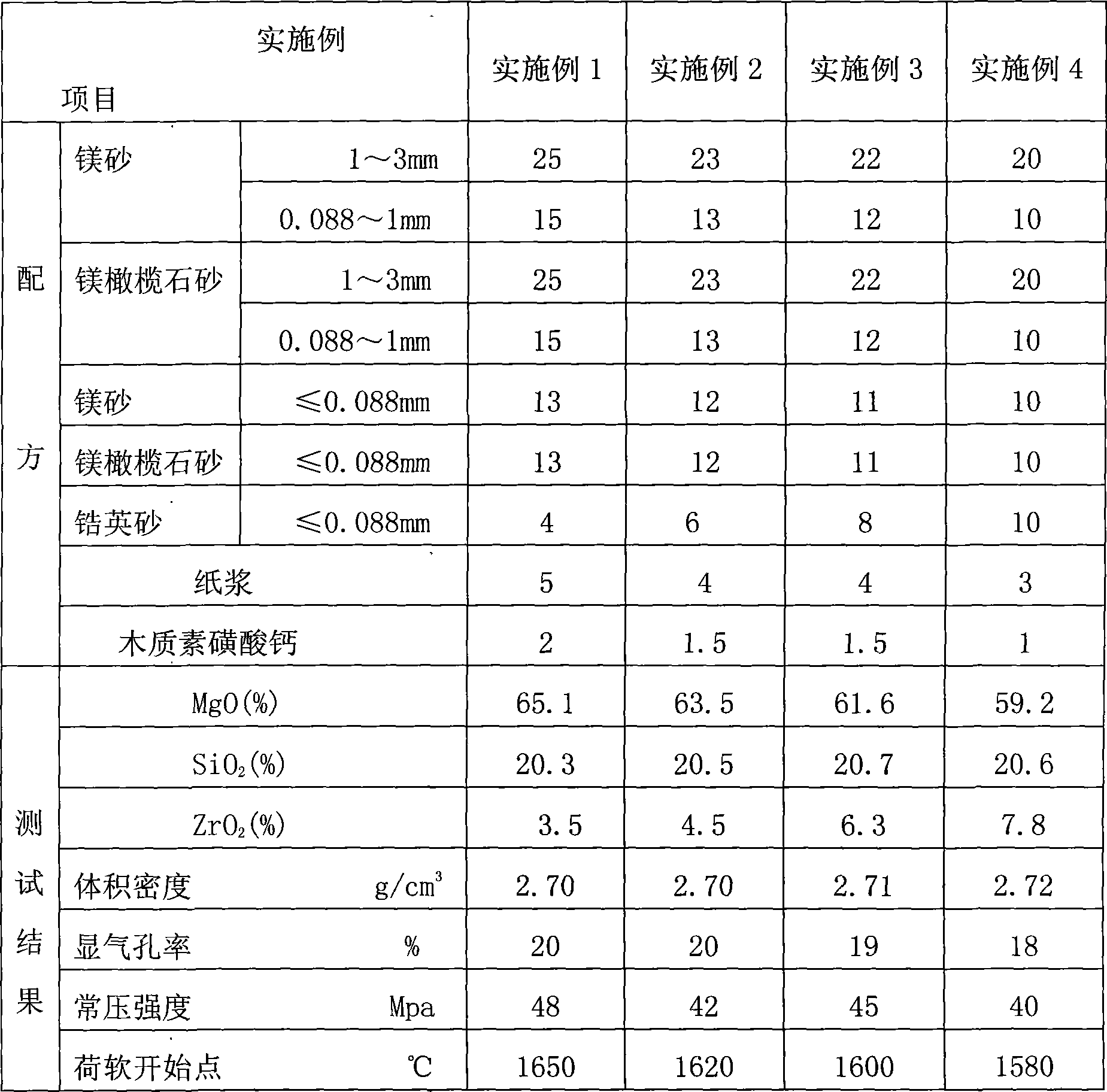

[0027] 2) Mixing: According to the weight ratio in Table 1, weigh the pellets of magnesia and forsterite sand with a particle size of 1 mm to 3 mm and a particle size of 0.088 mm to 1 mm, and add them to the sand mixer for dry mixing for 3 minutes , then add pulp waste liquid and calcium lignosulfonate, wet mix for 3 minutes, then add magnesia fine powder, forsterite sand fine powder and zircon sand fine powder with particle ...

Embodiment 2

[0034] The manufacture method of a kind of forsterite zirconium brick is as follows:

[0035] 1) Crushing and screening of raw materials: crush magnesia (MgO 96%) and forsterite sand in a crusher or a ball mill, and sieve through a 3mm sieve, a 1mm sieve and a 0.088mm sieve respectively to make a particle size of Magnesia and forsterite sand of 1mm to 3mm, magnesia and forsterite sand with a particle size of 0.088mm to 1mm, fine powder of magnesia and forsterite sand with a particle size of ≤0.088mm; zircon sand ( ZrO 66%) made particle size ≤ 0.088mm;

[0036] 2) Mixing: According to the weight ratio in Table 1, weigh the pellets of magnesia and forsterite sand with a particle size of 1 mm to 3 mm and a particle size of 0.088 mm to 1 mm, and add them to the sand mixer for dry mixing for 4 minutes , then add pulp waste liquid and calcium lignosulfonate, wet mix for 5 minutes, then add magnesia fine powder, forsterite sand fine powder and zircon sand fine powder with particle ...

Embodiment 3

[0043] The manufacture method of a kind of forsterite zirconium brick is as follows:

[0044] 1) Crushing and screening of raw materials: crush magnesia (MgO 96.8%) and forsterite sand in a crusher or a ball mill, and sieve through a 3mm sieve, a 1mm sieve and a 0.088mm sieve respectively to make a particle size of Magnesia and forsterite sand of 1mm to 3mm, magnesia and forsterite sand with a particle size of 0.088mm to 1mm, fine powder of magnesia and forsterite sand with a particle size of ≤0.088mm; zircon sand ( ZrO 66.5%) made particle size ≤0.088mm;

[0045] 2) Mixing: According to the weight ratio in Table 1, weigh the pellets of magnesia and forsterite sand with a particle size of 1 mm to 3 mm and a particle size of 0.088 mm to 1 mm, and add them to the sand mixer for dry mixing for 4 minutes , then add pulp waste liquid and calcium lignosulfonate, wet mix for 6 minutes, then add magnesia fine powder, forsterite sand fine powder and zircon sand fine powder with partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com